Hyundai Tucson: Roll rod bracket

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

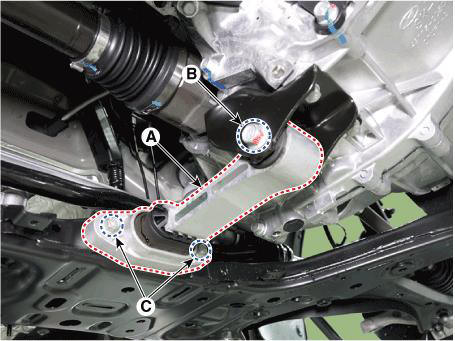

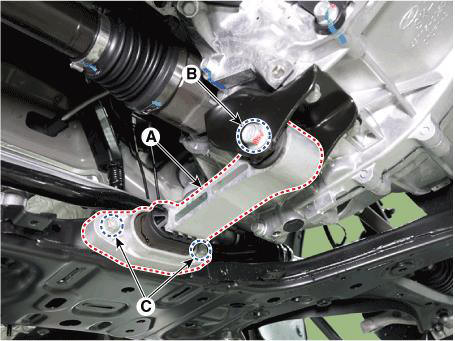

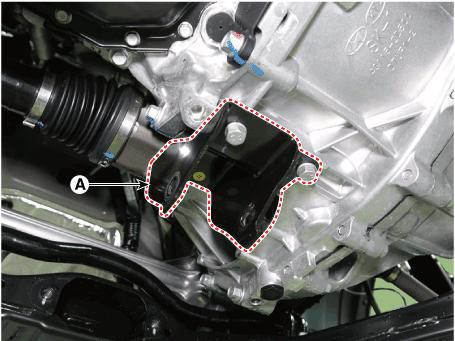

- Remove the roll rod bracket (A).

Tightening torque :

Bolt (B): 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

Bolts (C): 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

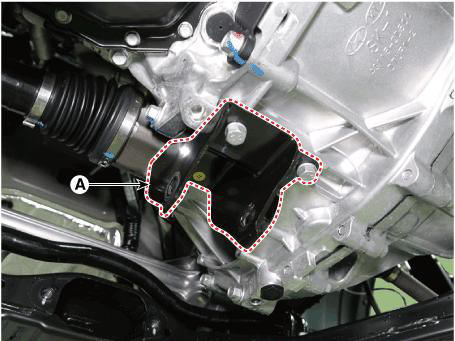

- Remove the roll rod support bracket (A).

Tightening torque : 49.0 - 68.6 N.m (5.0 - 7.0 kgf.m, 36.2 - 50.6 lb-ft)

- Installation is in the reverse order of removal.

Removal

WARNING

- Use fender covers to avoid damaging painted surfaces.

- To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

WARNING

Mark all wiring connector and hoses to avoid misconnection.

- Disconnect the negative battery terminal.

- Remove the engine cover.

(Refer to Engine and Transaxle Assembly - "Engine Cover")

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the coolant.

(Refer to Cooling System - "Coolant")

- Recover the A/C refrigerant and then remove the high & low pressure pipes of A/C compressor.

(Refer to Heating, Ventilation Air conditioning - "Refreigerant Line")

- Remove the air duct and air cleaner assembly.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

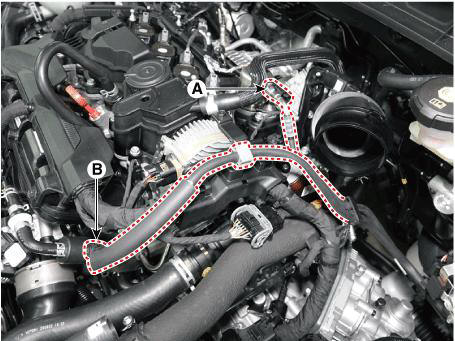

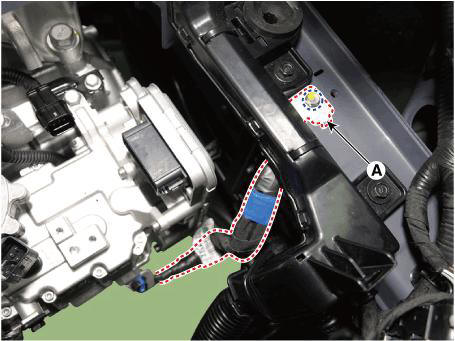

- Disconnect the brake booster vacuum hose (A).

- Disconnect the fuel hose (A) and PCSV hose (B).

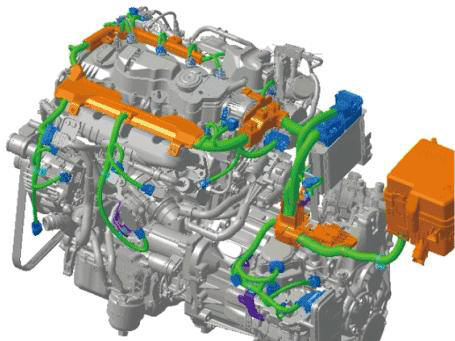

- Disconnect the wiring connectors and harness clamps and remove the connector brackets around the engine and transaxle assembly.

- Disconnect the engine ground cable (A).

Tightening torque : 6.8 - 9.8 N.m (0.7 - 1.0 kgf.m, 5.1 - 7.2 lb-ft)

- Disconnect the transaxle ground cable (A).

Tightening torque : 10.8 - 13.7 N.m (1.1 - 1.4 kgf.m, 8.0 - 10.1 lb-ft)

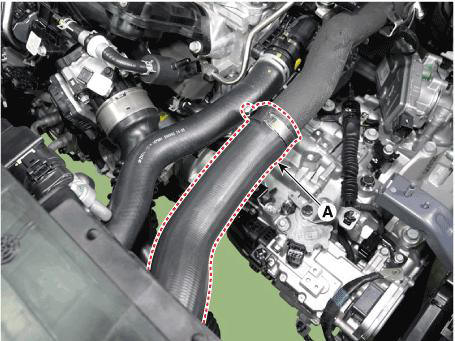

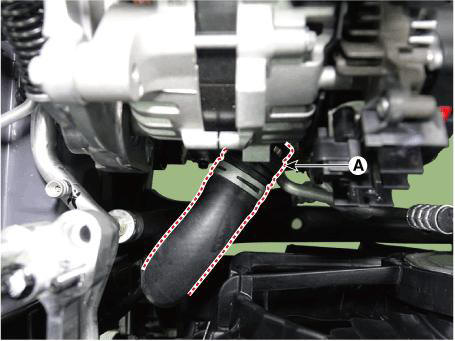

- Disconnect the intercooler inlet hose (A).

Tightening torque : Clamp bolt: 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

WARNING

Insert the hose until it reaches the end of stopper.

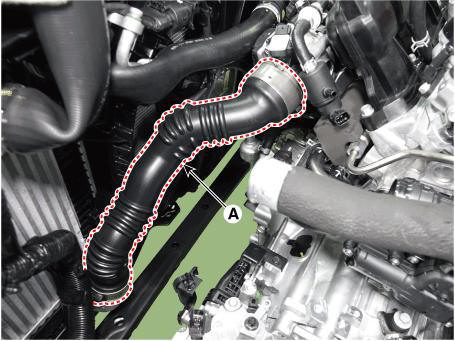

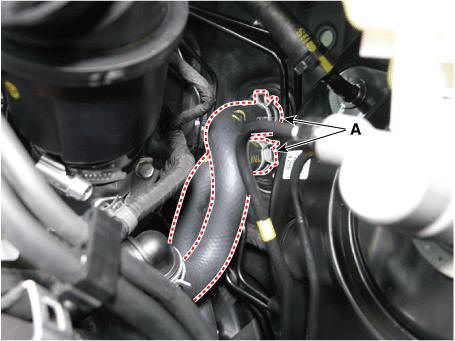

- Remove the intercooler outlet hose (A).

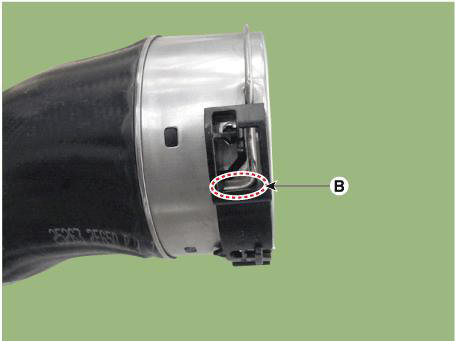

WARNING

1) When disconnecting the intercooler hose, pull the quick connector

clamp (A) in the direction of the

arrow as below.

2) Move the quick connector clamp from B to C position as below and

then disconnect by pulling the

quick connector hose.

- Disconnct the radiator upper hose (A).

- Disconnct the radiator lower hose (A).

- Disconnect the coolant reservoir tank water hoses (A).

- Disconnect the heater hoses (A).

- Remove the universal joint from the shaft joint

(Refer to Steering System - "Steering Gear Box")

- Remove the front muffler.

(Refer to Intake And Exhaust System - "Muffler")

- Remove the propeller shaft. 4WD

(Refer to Driveshaft and Axle - "Propeller Shaft")

- Remove the roll rod bracket (A).

Tightening torque :

Bolt (B): 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

Bolts (C): 49.0 - 63.7 N.m (5.0 - 6.5 kgf.m, 36.2 - 47.0 lb-ft)

- Remove the roll rod mounting support bracket (A).

Tightening torque : 49.0 - 68.6 N.m (5.0 - 7.0 kgf.m, 36.2 - 50.6 lb-ft)

- Remove the sub frame.

(Refer to Suspension System - "Sub frame")

- Support the engine and transaxle assembly safely with a floor jack.

- Remove the engine mounting support bracket (A).

Tightening torque : Bolt and Nut (B, C) : 88.3 - 107.9 N.m (9.0 - 11.0 kgf.m, 65.1 - 79.6 lb-ft)

- Remove the LH front wheel guard.

(Refer to Body (Interior and Exterior) - "Front Wheel Guard")

- Loosen the transaxle support bracket mounting bolts (A).

Tightening torque :

107.9 - 127.5N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

- Remove the engine and transaxle assembly from a vehicle by slowly lifting off the vehicle

WARNING

- Before removing the engine assembly, make sure to check that the hoses and wire connectors are completely disconnected.

- When removing the engine and transaxle assembly, be careful not to damage any surrounding parts or body components.

- Install in the reverse order of removal.

WARNING

- Refill a radiator and a reservoir tank with engine coolant.

(Refer to Cooling System - "Coolant")

- Check the engine oil level.

If necessary, refill engine with engine oil.

- Check the transaxle oil level.

If necessary, refill a transaxle with fluid.

- Charging the refrigerant gas.

- Inspect for fuel leakage.

READ NEXT:

Air Cleaner Assembly

Air Cleaner Assembly

Removal and

Installation

Disconnect the battery negative terminal.

Disconnect the air flow sensor (AFS) connector (A).

Remove the air duct (A).

Disconnect the RCV hose (A).

Remove the air cleaner assembly

Tight

Air Cleaner Element Replacement

Air Cleaner Element Replacement

Open the air cleaner element cover (A) by lifting up the air cleaner

element cover handle.

Unlock the air cleaner element camshaft (A) by turning in the direction

of arrow.

Replace the air cleaner element (A) with a new o

SEE MORE:

Front Suspension System- Removal

Front Suspension System- Removal

Removal

WARNING

When lifting a vehicle using a lift, be careful not to damage the

lower parts of the vehicle (floor under

cover, fuel filter, fuel tank, canister).

(Refer to General Information - "Lift Point")

Loosen the front w

Vehicle settings (infotainment system)

Vehicle settings (infotainment system)

Vehicle Settings in the infotainment

system provides user options for a

variety of settings including door lock/

unlock features, convenience features,

driver assistance settings, etc.

Vehicle Settings menu

Driver Assistance

Clus

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual