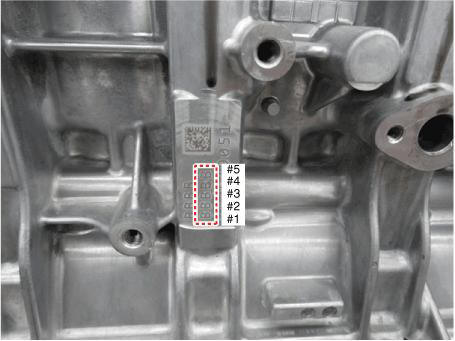

Hyundai Tucson: Cylinder Block Crankshaft Journal Bore Mark Location

Letters have been stamped on the side surface of the block as a mark for the size of each of the 5 main journal bores.

Use them, and the numbers or letters stamped on the crank (marks for main journal size), to choose the correct bearings.

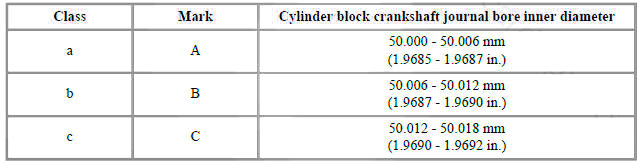

Crankshaft Main Journal Mark Location

Discrimination Of Crankshaft Main Journal

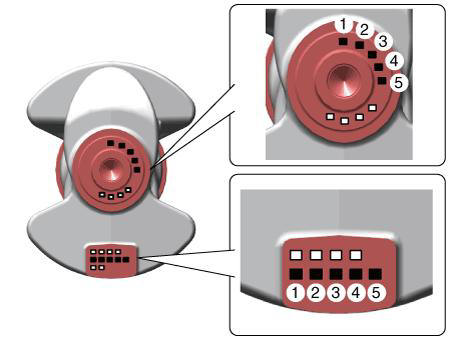

Crankshaft Bearing Identification Mark Location

No. 2, No. 4 Journal Upper Bearing

No. 1, No. 3, No. 5 Journal Upper Bearing

Lower Bearing

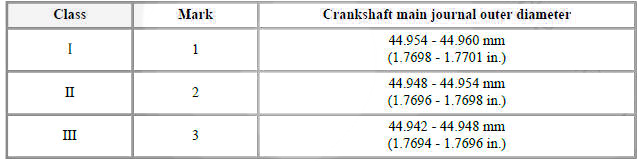

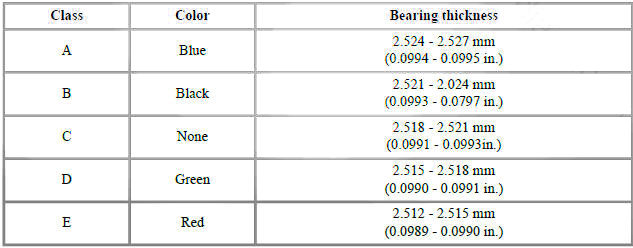

Discrimination Of Crankshaft Bearing

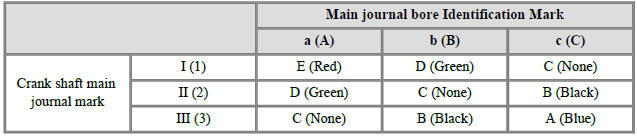

(7) Select the bearing by using selection table.

Crankshaft Main Bearing Selection Table

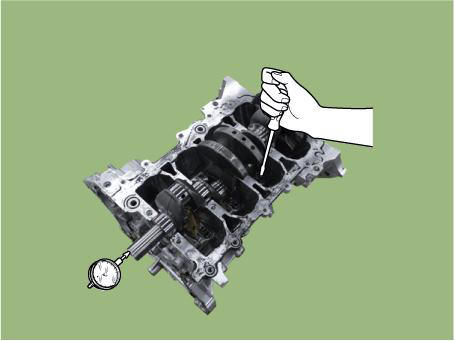

- Check the crankshaft end play.

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

Crankshaft end play 0.100 - 0.280 mm (0.0039 - 0.0110 in.)

If the end play is greater than maximum, replace the thrust bearings as a set.

Thickness of thrust bearing : 2.910 - 2.950 mm (0.1146 - 0.1161 in.)

- Inspect the crankshaft main journals and pin journals.

Using a micrometer, measure the diameter of each main journal and pin journal.

Main journal diameter : 44.942 - 44.960 mm (1.7694 - 1.7701 in.)

Crank pin diameter : 41.954 - 41.972 mm (1.6517 - 1.6524 in.)

READ NEXT:

Piston Pin - Reassembly

Piston Pin - Reassembly

WARNING

Thoroughly clean all parts to assembled.

Before installing the parts, apply fresh engine oil to all

sliding and rotating surfaces.

Always use new gaskets, O-ring and oil seals.

Install the crankshaft position sensor wheel

Cylinder Block/ Disassembly/ Inspection/ Reassembly

Cylinder Block/ Disassembly/ Inspection/ Reassembly

WARNING

Use fender covers to avoid damaging painted surfaces.

To avoid damage, unplug the wiring connectors carefully while

holding the connector portion.

WARNING

Mark all wiring connector and hoses to avoid misconnection.

To releas

Cylinder Head Assembly

Cylinder Head Assembly

Components

Front camshaft bearing cap

Intake camshaft bearing cap

Exhaust camshaft bearing cap

Cam carrier

Fuel pump adaptor

Engine hanger

Cylinder head

Cylinder head gasket

Intake OCV center bolt

Intake OCV center bolt

SEE MORE:

Description of ESP

Description of ESP

Electronic Stability Control (ESC) recognizes critical driving conditions,

such as panic reactions in dangerous situations, and

stabilizes the vehicle by individual wheel braking and engine control input.

ESC adds an additional function known a

Brake Pedal - Removal

Brake Pedal - Removal

Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

Remove the crash pad lower panel.

(Refer to Body - "Crash Pad Lower Panel")

Disconnect the stop lamp switch connector (A).

Pull the locking plate (A)

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual