Hyundai Tucson: Release Residual Pressure in Fuel Line

WARNING

There may be some residual pressure even after "Release Residual Pressure in Fuel Line" work, so cover the hose connection with a shop towel to prevent residual fuel from spilling out before disconnecting any fuel connection.

- Turn the ignition switch OFF and disconnect the battery (-) cable.

- Remove the fuel pump fuse (A).

WARNING

When removing the fuel pump relay, the Diagnostic Trouble Code (DTC) will be occurred.

Therefore delete the code with the diagnostic tool after "Release Residual Pressure in Fuel Line" work.

- Connect the battery (-) cable.

- Start the engine and let idle, and then turn the ignition switch OFF after the engine has stopped on its own.

- Disconnect the battery (-) cable, and then install the fuel pump relay (A).

- Connect the battery (-) cable.

- Delete the Diagnostic Trouble Code (DTC) related the fuel pump relay with the diagnostic tool.

Removal

WARNING

Be careful not to damage the parts located under the vehicle (floor under cover, canister, fuel tank) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Support Points")

- Release the residual pressure in fuel line.

(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line")

- Turn the ignition switch OFF and disconnect the batteiy (-) terminal.

- Remove the rear seat cushion.

(Refer to Body - "Rear Seat Assembly")

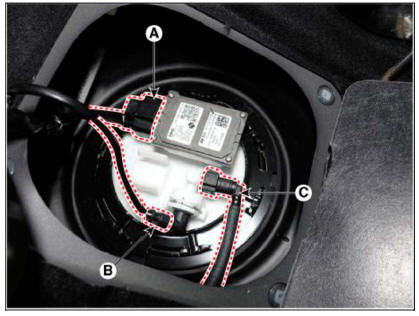

- Remove the fuel pump service cover (A) after loosening the screw.

- Disconnect the Fuel Pump Control Module (FPCM) connector (A).

- Disconnect the Fuel Pressure Sensor (FPS) connector (B).

- Disconnec the fuel feed tube quick-connector (C).

- Lift the vehicle.

- Remove the propeller shaft assembly 4WD.

(Refer to Driveshaft and Axle - "Propeller shaft Assembly")

- Remove the center muffler.

(Refer to Engine Mechanical System - "Muffler")

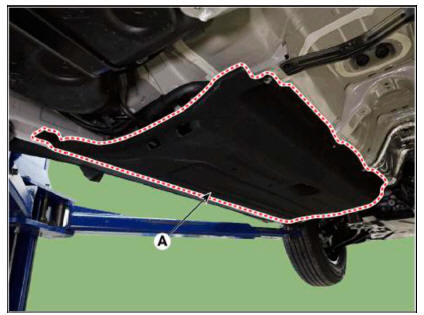

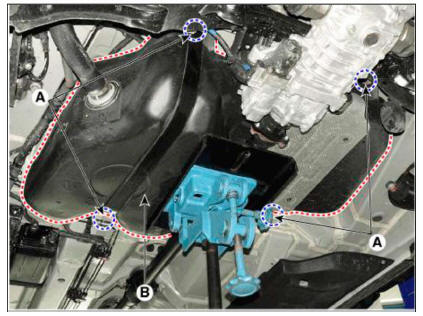

- Remove the floor under cover (A).

Tightening torque : 7.9 - 11.8 N m (0.8 - 1.2 kgf m, 5.8 - 8.7 lb ft)

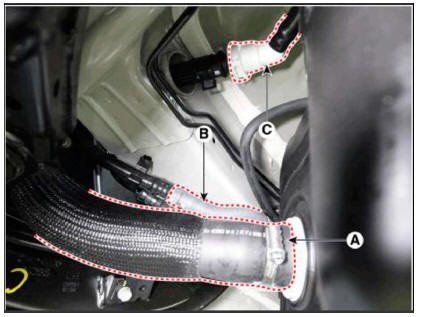

- Separate the fuel filler hose (A).

- Separate the fuel ventilation hose (B) and then remove the fixing clip (D).

- Disconnect the levelling hose quick-connector (C).

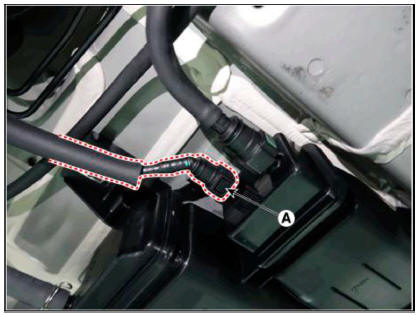

- Disconnect the vapor hose quick-connector (A).

- Support the fuel tank with a jack (A).

WARNING

Insert the rubber block between the fuel tank and jack to prevent damage to the fuel tank.

- Remove the fuel tank (B) after loosening the mounting bolt (A).

Tightening Torque : 39.2 - 53.9 N.m (4.0 - 5.5 kgf.m, 28.9 - 39.8 lb-ft)

Installation

- Install in the reverse order of removal.

READ NEXT:

Fuel pump service

Fuel pump service

Inspection

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Remove the fuel pump assembly.

(Refer to - "Removal" Procesures)

Using an ohmmeter, measure the resistance between terminals 1 and 6 of

sender

Fuel pump service -

Installation

Fuel pump service -

Installation

Installation

Install in the reverse order of removal.

Removal

Remove the fuel pump.

(Refer to Fuel Delivery System - "Fuel Pump")

Disconnect the fuel sender connector (A).

Release the fixing hook (A) and then remo

Low Pressure Fuel Line

Low Pressure Fuel Line

WARNING

Be careful not to damage the parts located under the vehicle (floor

under cover, canister, fuel tank) when

raising the vehicle using the lift.

(Refer to General Information - "Lift and Support Points")

Release the residua

SEE MORE:

Air ventilation seat

Air ventilation seat

The air ventilation seats are provided

to cool the front seats by blowing air

through small vent holes on the surface

of the seat cushions and seatbacks.

When the operation of the air ventilation

seat is not needed, keep the switches in

t

Side airbag (SAB)

Side airbag (SAB)

Components Location

Side airbag (SAB)

Removal

Disconnect the batteiy negative terminal.

WARNING

After disconnecting the cables, wait at least 3 minutes.

Remove the front seat back cover.

(Refer to Body - "Front Seat Back

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual