Hyundai Tucson: Coupling Assembly - Description

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / Wheel Drive (4WD) System / Coupling Assembly / Coupling Assembly - Description

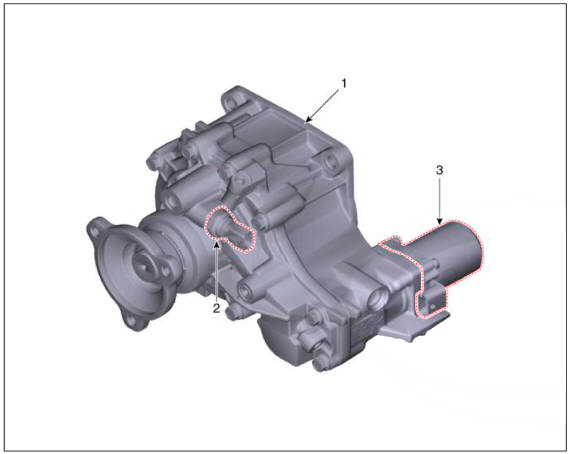

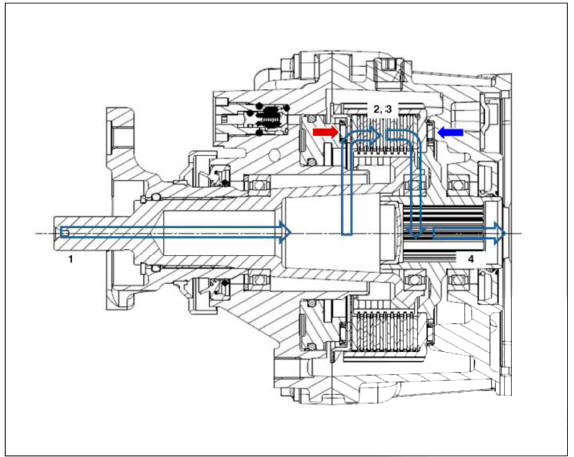

Component Location

- Coupling assembly

- Pressure sensor

- Oil hydraulic motor

Description

4\VD ECU processes signals from various sensors and determines the current road and driving conditions. The ECU then utilizes this information to implement precision control over the 4WD coupling's multi-plate clutch and variably adjust the amount of torque delivered tothe rear wheels.

Four Wheel Drive (4WD) transfer mode selection

- AUTO MODE:

- When driving in 4WD AUTO mode, the vehicle operates similar to conventional 2WD vehicles under normal operating conditions. However, if the system determines that there is a need for the 4WD mode, the engine's driving power is distributedto all four wheels automatically without driver intervention.

- When driving 011 normal roads and pavement, the vehicle moves similar to conventional 2WD vehicles.

- LOCK MODE:

- This mode is used for climbing or descending sharp grades, off-road driving, driving on sandy and muddy roads, etc., to maximize traction.

- However, binding may occur in LOCK MODE when circling and it does not operate when the vehicle speed is over 60 km/h.

Electronic Coupling - 4WD Control (By Driving Condition)

- Cruising (Auto Mode)

- Power is delivered mostly to the front wheels.

- Cornering (Auto Mode)

- Adjusts the amount of power to the rear wheels based on the turning radius and cornering speed.

- Wheel Slip (Auto Mode)

- f one or both of the front wheels lose traction, the system transfers an appropriate amount of power to the rear wheels based 011 the slip amount at the front wheels.

Operation

Electronic Coupling

- The power is delivered in the following order: Transmission -> Transfer -> Propeller shaft

- AWD ECU calculates the necessary amount of rear-wheel torque and sends the corresponding driving current to the actuator (electronic motor and hydraulic pump).

- The piston operates by the oil pressure and the friction is generated. Then, the clutch is engaged.

- The power is delivered to the differential by the engaged clutch and the driving power is generated in to the rear wheel.

READ NEXT:

Coupling Assembly- Removal

Coupling Assembly- Removal

Inspection

WARNING

All units are filled up with coupling fluid (ultra-low viscosity ATF)

prior to shipping. Inspection, fillup,

and replacement of coupling fluid is therefore not necessary (zero maintenance,

lifetime fluid).

Removal

WARNING

Coupling Assembly- Installation

Coupling Assembly- Installation

To install, reverse the removal procedures.

WARNING

Smear the splines (A) with molybdenum type high pressure grease.

When install the coupling, be careful not to damage the oil

seal (B).

After replacing the coupling, reset the 4

Oil Hydraulic Motor (Actuator) Inspection Procedure

Oil Hydraulic Motor (Actuator) Inspection Procedure

Removal

Remove the coupling assembly.

(Refer to 4 Wheel Drive (4WD) System - "Direct Electro Hydraulic Actuator

Coupling")

Keep going perpendicular state after remove the coupling assembly.

WARNING

Keep going perpend

SEE MORE:

Explanation of scheduled maintenance items

Explanation of scheduled maintenance items

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the vehicle

is being driven in severe conditions,

more frequent oil and filter changes are

required.

Drive belts

Insp

PAB ON/OFF Switch

PAB ON/OFF Switch

Components Location

PAB ON/OFF Switch

Removal

Disconnect the battery negative terminal.

WARNING

After disconnecting the cables, wait at least 3 minutes.

Remove the crash pad side cover.

(Refer to Body - "Crash Pad Side C

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual