Hyundai Tucson: Camshaft - Inspection

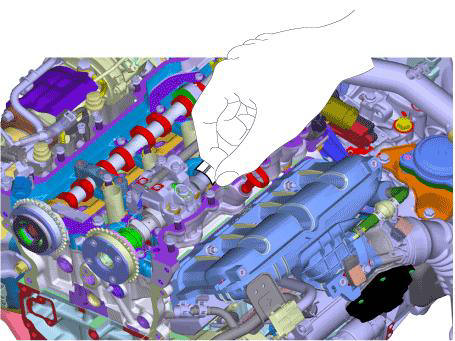

- Measure the height of the cam.

Check the surface of the cam lob for wear and tear. If necessary, replace the camshaft.

Cam height

Intake : 37.33 mm (1.4697 in.)

Exhaust : 37.44 mm (1.474 in.)

- Inspect the camshaft journal clearance.

(1) Clean the camshaft journals and bearing caps.

(2) Place the camshafts on the cam carrier.

(3) Lay a strip of plasticgauge across each of the camshaft journals.

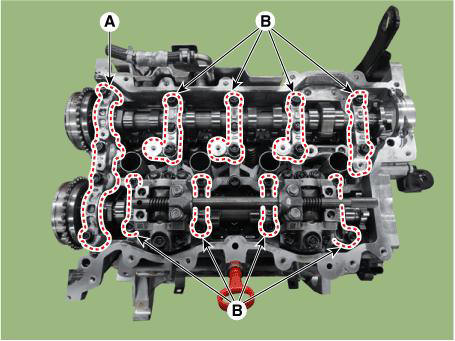

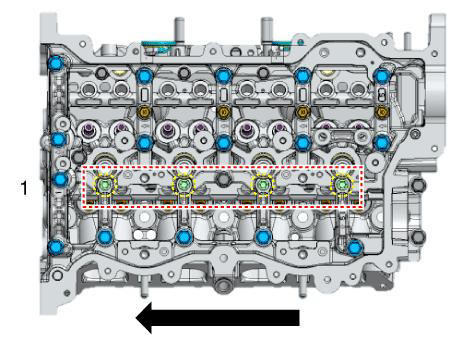

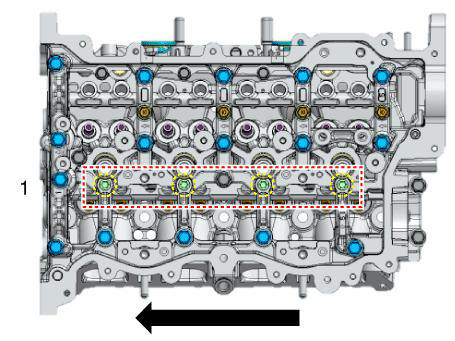

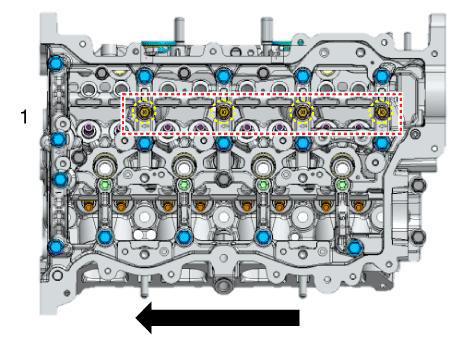

(4) Install the camshaft front bearing cap (A) and camshaft bearing caps (B).

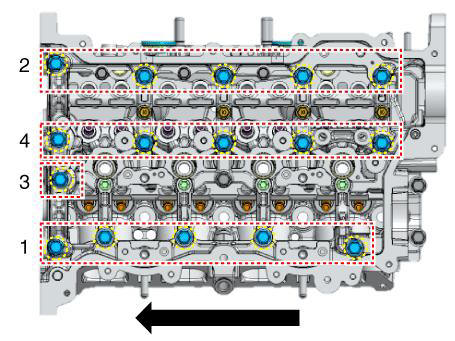

1) Install the camshaft front bearing cap and camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

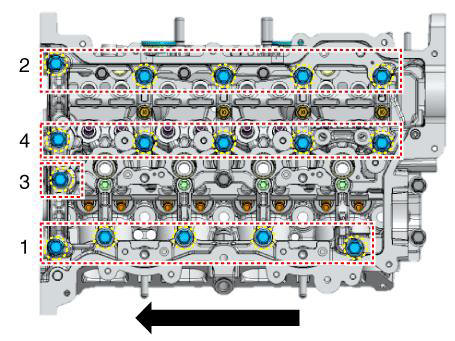

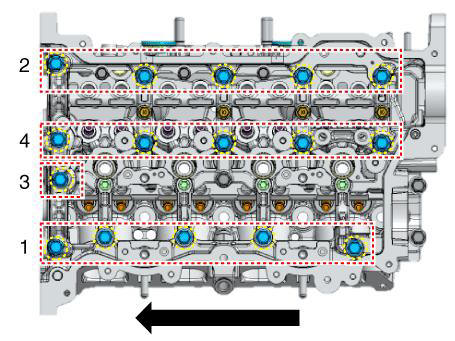

2) Install the camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

3) Install the camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

4) Install the camshaft front bearing cap and camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

5) Install the camshaft front bearing cap and camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 18.6 - 22.6 N.m (1.9 - 2.3 kgf.m, 13.7 - 16.6 lb-ft)

6) Install the camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 11.8 - 13.7 N.m (1.2 - 1.4 kgf.m, 8.7 - 10.1 lb-ft)

7) Install the camshaft bearing cap installing bolt with direction from back of engine to the front of engine according to the procedure at down below.

Tightening torque : 11.8 - 13.7 N.m (1.2 - 1.4 kgf.m, 8.7 - 10.1 lb-ft)

(5) Remove the camshaft bearing caps.

(6) Measure the plasticgauge at the widest point.

If the oil clearance is greater than the specification, replace the camshaft.

If necessary, replace the bearing caps and cam carrier.

Cam height

No.1 : 0.040 - 0.071 mm (0.0016 - 0.0028 in.)

No.2, 3, 4, 5 : 0.035 - 0.065 mm (0.0014 - 0.0026 in.)

(7) Remove the plasticgauge.

(8) Remove the camshafts.

- Inspect the camshaft end play.

(1) Install the camshafts.

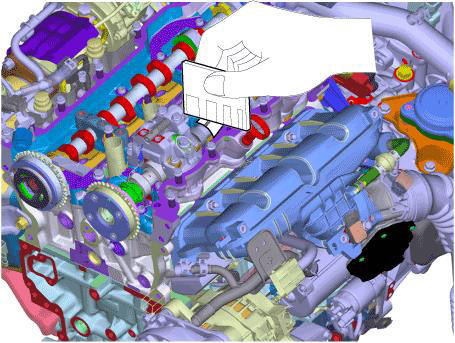

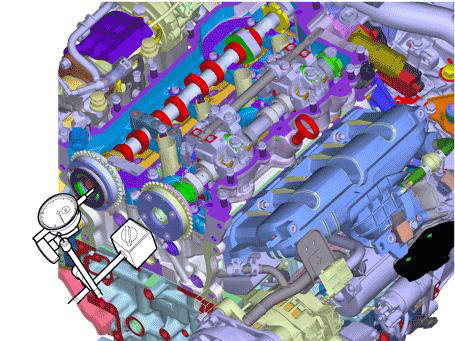

(2) Measure the end play while moving the camshaft back and forth using a dial gauge.

Camshaft end play

Standard value : 0.10 - 0.19 mm (0.0039 - 0.0075 in.)

If the end play is greater than the specification, replace the camshaft. If necessary, replace the cylinder head

READ NEXT:

Camshaft - Installation

Camshaft - Installation

Install the intake CVVT (A).

Install the CVVD assembly (A).

WARNING

After installing the CVVD, check whether the swing arm is

separated or is installed correctly.

When installing the intake camshaft, spray the engine oil

Camshaft - Description

Camshaft - Description

CVVD (Continuous Variable Valve Duration) System is a device to control the

optimum open and close timing according to

the driving mode by changing the valve opening section.

It is composed of cam shaft, CVVD assembly, and CVVD acatuator.

Th

When not using the CVVD fixture

When not using the CVVD fixture

(3) Remove the CVVD assembly.

Remove the Intake CVVT (A).

Installation

Install the Intake CVVT (A).

Install the CVVD assembly (A).

WARNING

After installing the CVVD, check whether the swing arm is

separated

SEE MORE:

Brake Tube Engine Room

Brake Tube Engine Room

Components

Removal

WARNING

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and

canister) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Su

Glass Adjustment

Glass Adjustment

WARNING

Check the glass run channel for damage or deterioration, and replace

it if necessary.

Remove the front door trim.

(Refer to Front Door - "Front Door Trim")

Lower the glass by operating the power window switch until the gl

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual