Hyundai Tucson: When Using the CVVD fixture

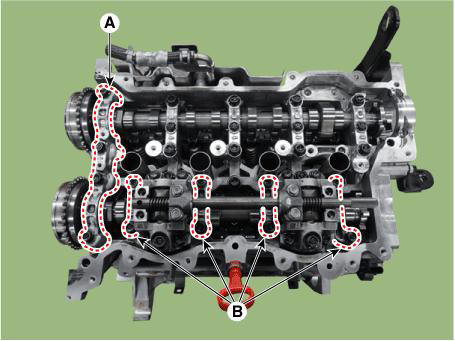

- When installing the CVVD assembly mounting bolts (M6), tighten sequence shown.

Tightening torque : 1ST 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

2nd 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

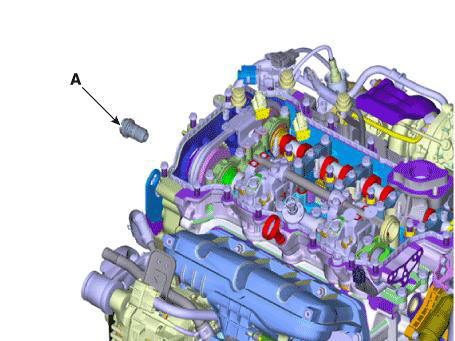

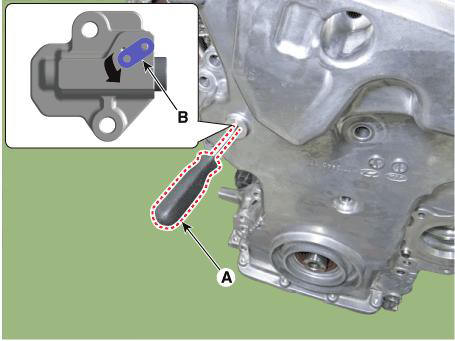

- Remove the CVVD fixture (A).

- Provisionally tighten the CVVD assembly mounting bolts (M8) in sequence shown below.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

- Remove the CVVD assembly mounting bolts (M6) (A).

- Provisionally tighten the CVVD assembly mounting bolts (M6) in sequence shown below.

Tightening torque : 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

- Tighten the CVVD assembly mounting bolts (M8) in sequence shown below.

Tightening torque : 18.6 - 22.6 N.m (1.9 - 2.3 kgf.m, 13.7 - 16.6 lb-ft)

- Tighten the CVVD assembly mounting bolts (M6) in sequence shown below.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

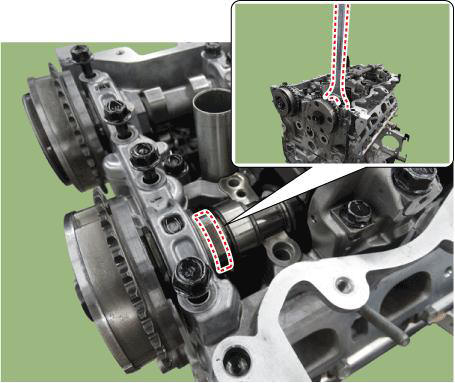

- Measure the clearance between the control shaft bearing cap and the end of control shaft using a clearance gauge.

Clearance : 0.0 - 0.05 mm (0.0 - 0.002 in.)

When not using the CVVD fixture

Provisionally tighten the CVVD assembly mounting bolts (M6) in sequence shown below

Tightening torque : 4.9 - 6.9 N.m (0.5 - 0.7 kgf.m, 3.6 - 5.1 lb-ft)

- Provisionally tighten the CVVD assembly mounting bolts (M8) in sequence shown below.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

- Tighten the CVVD assembly mounting bolts (M8) in sequence shown below.

Tightening torque : 18.6 - 22.6 N.m (1.9 - 2.3 kgf.m, 13.7 - 16.6 lb-ft)

- Tighten the CVVD assembly mounting bolts (M6) in sequence shown below.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

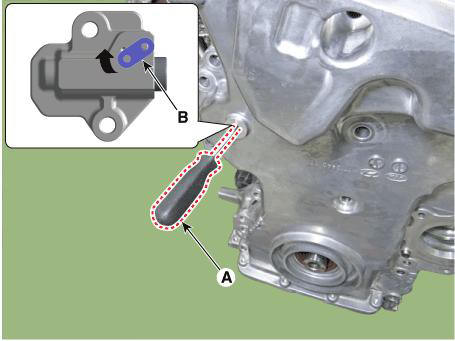

- Release the torque of control shaft bearing cap bolt (A).

- Push the control shaft bearing cap as close as possible in the direction of the arrow

- Install the control shaft bearing cap mounting bolts (A).

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

- Measure the clearance between the control shaft bearing cap and the end of control shaft using a clearance gauge.

Clearance : 0.0 - 0.05 mm (0.0 - 0.002 in.)

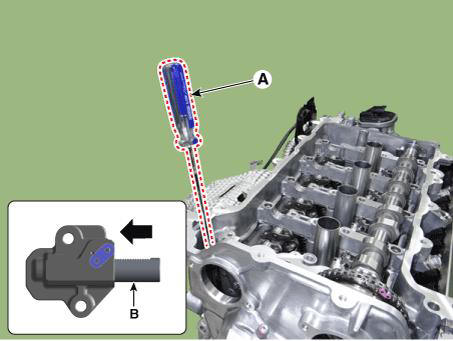

- Install the intake OCV & center bolt (A).

Tightening torque : 22.6 - 26.5 N.m (2.3 - 2.7 kgf.m, 16.6 - 19.5 lb-ft) + 32 - 36º

WARNING

- To prevent impurities from entering intake oil control valve (OCV) & center bolt, wear rubber gloves.

- Intake oil control valve (OCV) and center bolt, hold the

hexagonal portion on the camshaft with a wrench

to prevent the camshaft from rotating.

- Compress the timing chain tensioner piston.

(1) With a pry bar (A), compress the timing chain tensioner piston (B).

(2) With a thin gimlet (A), raise the ratchet plate (B) of the timing chain tensioner and fix the piston.

WARNING

Do not remove the pick (A).

- Install the front bearing cap and camshaft bearing cap

WARNING

If there is enough engine oil on the camshaft front bearing cap and camshaft bearing cap installing bolt and bolt hole, tighten to the minimum required tightening torque.

Apply engine oil the upper part of the intake / exhaust camshaft journal, then install the camshaft front bearing cap and camshaft bearing cap. The amount of application should be enough to flow down both the front and back sides when it is applied to the center.

(1) Install the front bearing cap (A) and intake camshaft bearing cap (B).

- Remove the fine gimlets (A) that hold the timing chain tensioner.

- When installing the timing chain, be sure that the timing mark (A) of each sprocket is matched with the timing mark (B) (color link) of the timing chain.

READ NEXT:

Intake/Exhaust CVVT Timing Mark

Intake/Exhaust CVVT Timing Mark

Intake CVVT Timing Mark

Exhaust CVVT Timing Mark

Install the cam to cam guide (A).

Tightening torque :

9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

Install the intake variable force solenoid (VFS) valve (A).

Tightenin

Cylinder Head

Cylinder Head

Inspect for flatness.

Using a precision straight edge and feeler gauge, measure the contacting

surface of the cylinder block and the

manifolds for warpage

Flatness of cylinder head gasket surface:

Less than 0.05 mm (0.0020 in.) fo

Cylinder Head - Installation

Cylinder Head - Installation

WARNING

Thoroughly clean all parts to be assembled.

Always use a new cylinder head gasket and manifold gasket.

Always use a new cylinder head bolt and cylinder head bolt

washer.

The cylinder head and exhaust manifold is a metal gasket. T

SEE MORE:

Motor Driven Power Steering- Replacement

Motor Driven Power Steering- Replacement

Replacement

Turn the steering wheel so that the front wheels are placed in the

straight ahead position.

Turn the ignition switch OFF and disconnect the battery negative (-)

cable.

Remove the driver airbag (DAB).

(Refer to Restraint -

ECS (Electronic Control Suspension) System

ECS (Electronic Control Suspension) System

Description

Real-time continuous control of the damping force according to vehicle

running conditions and the

state of road surface will enhance ride comfort and steering safety, including

roll / pitch reduction in

case of vehicle dynamics con

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual