Hyundai Tucson: Motor Driven Power Steering - Description

Description

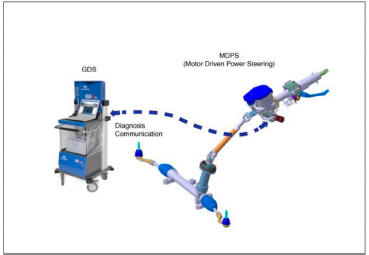

MDPS (Motor Dirven Power Steering) system uses an electric motor to assist the steering force and it is an engine operation independent steering system.

MDPS control module controls the motor operation according to information received from the each sensor and CAN (Controller Area Network), resulting in a more precise and timely control of steering assist than conventional engine-driven hydraulic systems, MDPS system inspection is possible for each component, but replacement is possible only for partial units, and other parts should not be disassembled.

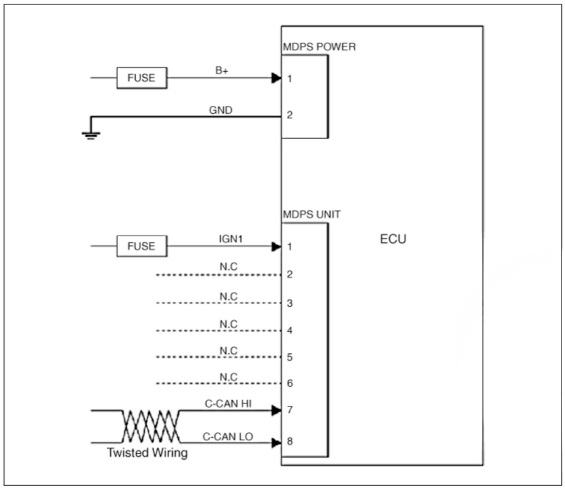

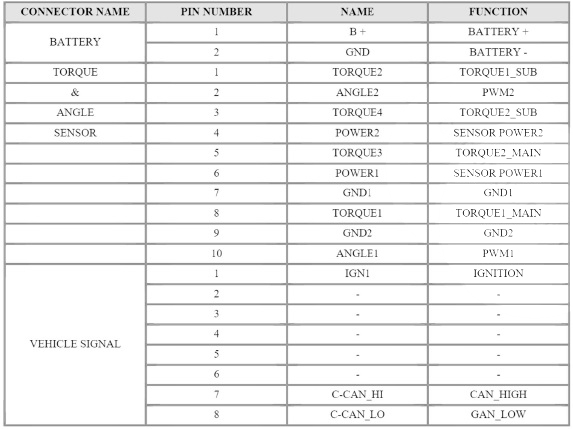

Schematic Diagrams

Harness Connector

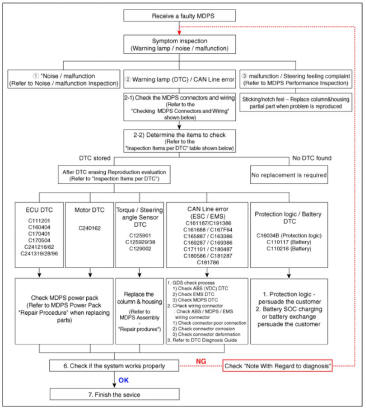

A/S Repair produres CMDPS

MDPS System A/ S Workflow

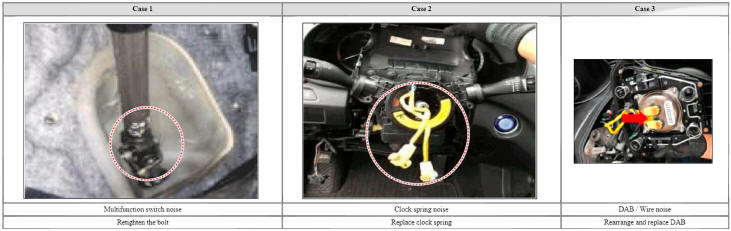

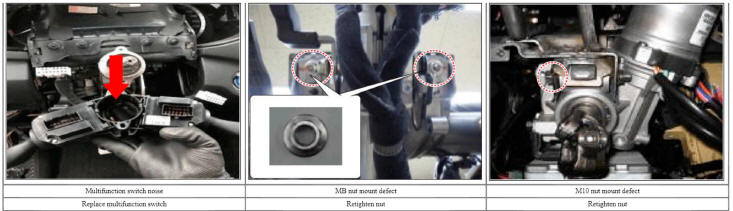

(1) Noise malfunction Inspection

(2) Warning lamp (DTC) / CAN Line error

2 - 1 Checking Connectors and Wiring

- Checking Connectors and Wiring.

Check for damage, push-back, or improper connection in each connector and wiring.

(1) Check the wiring on the vehicle side.

- Check for open short - circuit due to faulty connection, damage, or foreign substance.

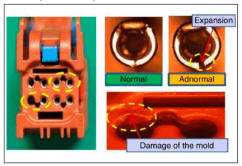

(2) Check the motor connector.

- Terminal Expansion and damage

WARNING

If a problem such as terminal expansion or damage occurs during the wiring inspection process, be sure to replace :he MDPS power pack assembly.

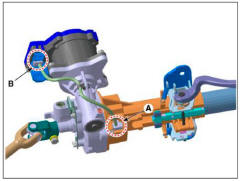

(3) Check TAS side (A) and powerpack side (B) wiring.

- Inspect each connector and wiring for damage, push backs, or incorrect

connections.

WARNING

- For DTC C125901 / C125929 / C125938 / C129002, replace the MDPS

wiring.

(Refer to Motor Driven Power Steering (MDPS) - "MDPS Wiring")

- If no problem is found during the MDPS wiring check, replace

the MDPS column & housing.

(Refer to Motor Driven Power Steering (MDPS) - "MDPS Column & Housing")

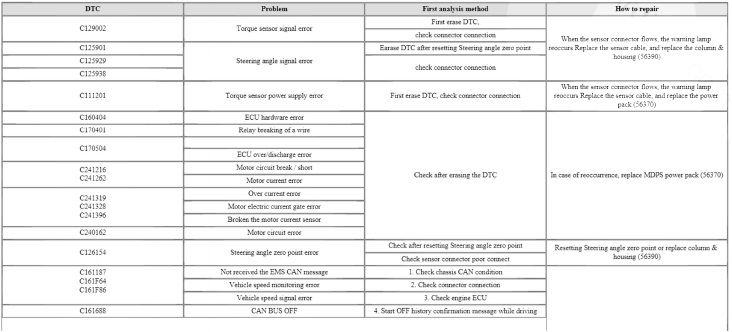

2 - 2 Inspection Items per DTC

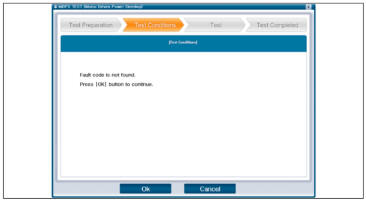

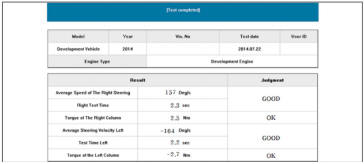

(3) MDPS Performance Inspection

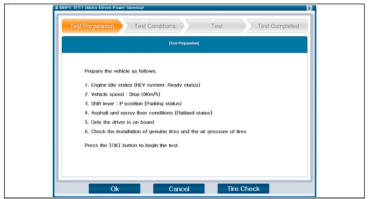

- This bulletin provides Motor Driven Power Steering (MDPS) diagnostic procedure using GDS to diagnose theheavy steering effort, abnormal position of steering parts and MIL illumination in steering system.

- GDS judges the MDPS normal abnormal state by calculating the MDPS motor

torque generated when turning the steering wheel to left and right at 360=

per 3 seconds.

- Connect self - diagnosis connector (16pins) located in the lower of driver side crash pad to self - diagnosis device.

- Turn the self - diagnosis device after key is ON.

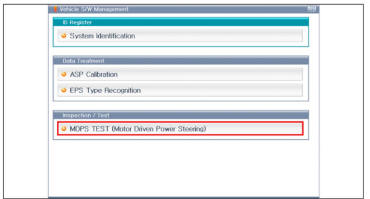

- After Selectmg the "vehicle model" and "system", select the "MDPS TEST"

on GDS vehicle selection screen.

- Prepare a vehicle according to the required vehicle's conditions.

- Search the DTCs relevant to the MDPS and then erase them if found.

- Perform me MDPS

TEST.

- If the results of MDPS performance inspection are "OK": click "OK" and

then finish the service work.

- If the results of MDPS inspection are "Check", click "Inspection" and then inspect below items.

(1) MDPS Warning light illuminated

- Inspect DTCs relevant to the steering system.

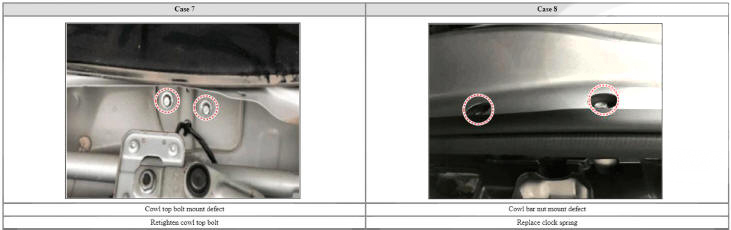

(2) Vibration and Noise

- Inspect MDPS portions where are mounted to the body. (Checking tightenmg conditions of bolts and nuts)

- Inspect universal joint mounting bolts.

(3) Inspection for heavy steering effort

- Inspect tire pressure and width.

- Check that the heavy steering effort occurs or not when vehicle speed is not received.

- Check DTCs relevant to the CAN communication error.

(4) MDPS common problems

WARNING

Cautions to be taken when handling the MDPS (Motor Driven Power Steering)

- Failure occurs due to internal damage because of the drop of and shock and excessive external force on the new partial component.

→ Be cautious of shock on the partial component and replace the damaged part (due to drop, etc.) with a new one.

- When fastening the steering, excessive impact may result in twisting the center point of the torque sensor.

- When removing installing the connector the wiring may be damaged (deformed) by excessive external force.

- Be cautious when storing and replacing the partial components under the abnormal temperature and humidity conditions.

A S Repair Procedures RMDPS

READ NEXT:

Column & Housing Noise Repair Guide

Column & Housing Noise Repair Guide

R-MDPS Warning lamp Diagnosis Guide

Inspection Items per DTC

Checking Connectors and Wiring

Checking Connectors and Wiring.

Check for damage, push-back, or improper connection in each connector and

wiring.

(1) Check th

Motor Driven Power Steering- Replacement

Motor Driven Power Steering- Replacement

Replacement

Turn the steering wheel so that the front wheels are placed in the

straight ahead position.

Turn the ignition switch OFF and disconnect the battery negative (-)

cable.

Remove the driver airbag (DAB).

(Refer to Restraint -

EPS Type Recognition

EPS Type Recognition

WARNING

When missing the EPS Type Recognition, occure a problem with motor

driven power steering performance

EPS Type Recognition procedures

Connect self-diagnosis connector(16pins) located in the lower of driver

side crash pad to self-dia

SEE MORE:

Reverse Parking Collision- Avoidance Assist Settings

Reverse Parking Collision- Avoidance Assist Settings

Reverse Parking Collision-Avoidance

Assist will warn the driver or will

assist with braking to help reduce the

possibility of collision with a pedestrian

or an object when backing up.

Detecting sensor

[1] : Rear view camera,

[2] : Rear ult

Power Relay (Type A)

Power Relay (Type A)

Component Location

Engine room junction block

ICU Junction block

Inspection

Power Relay (Type A)

There should be continuity between the No.30 and No.87 terminals when

power and ground are

connected to the No.85 and No.86

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual