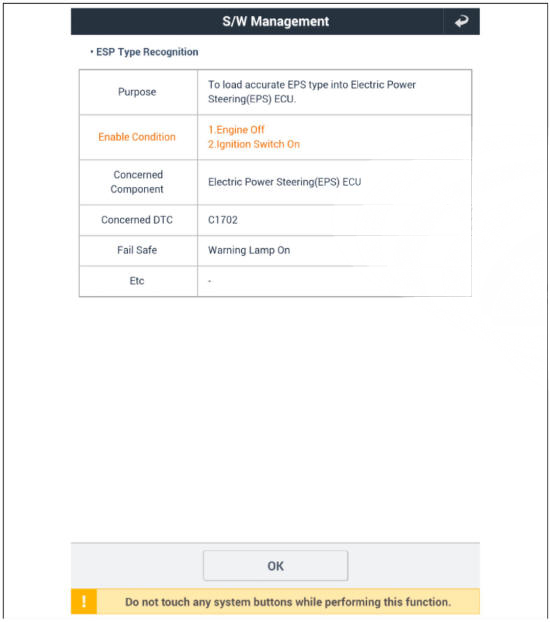

Hyundai Tucson: EPS Type Recognition

WARNING

When missing the EPS Type Recognition, occure a problem with motor driven power steering performance

EPS Type Recognition procedures

- Connect self-diagnosis connector(16pins) located in the lower of driver side crash pad to self-diagnosis device.

- Turn the self-diagnosis device after key is ON.

- Turn the steering wheel to straight ahead position.

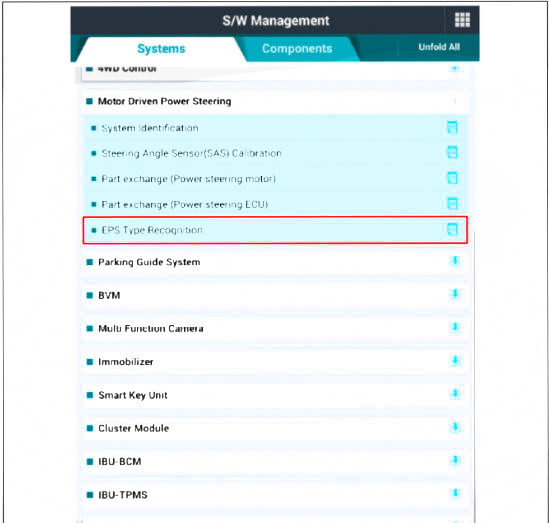

- After Selecting the "vehicle model" and "system", select the "EPS Type Recognition" on diagnostic tool vehicle selection screen.

- Remove the DTC.

- Turn off the IG switch and wait for 20 seconds or more before starting the engine. And then make sure that MDPS works properly.

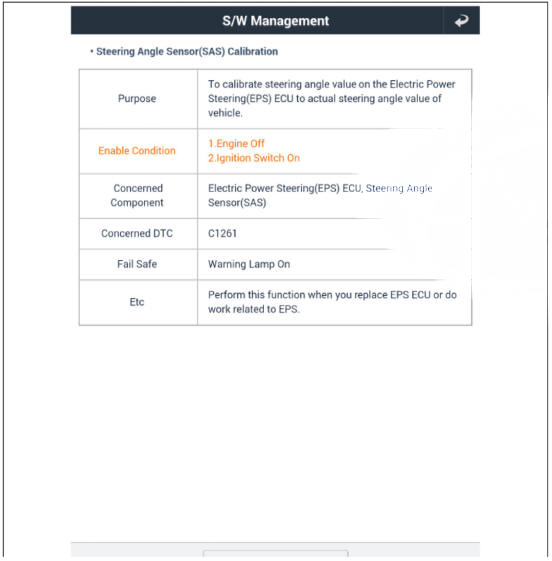

SAS Calibration

- Steering-angle sensor detects the steering angle and steering angle speed. Steering angle and steering angle speed are used for steering wheel damping and return controls in addition to providing assistance torque.

WARNING

- You can use a scan tool to (diagnostic tool) check if the battery voltage is proper before perform the "SAS Calibration".

- Make sure that no connector engaged to the vehicle or scan tool is disconnected during the "SAS Calibration".

- Once the "SAS Calibration" is complete, turn off the IG switch and wait for 10 seconds or more before starting the engine to check the operation.

SAS Calibration procedures

- Connect self - diagnosis connector (16pins) located in the lower of driver side crash pad to self - diagnosis device.

- Turn the self - diagnosis device after key is ON.

- Turn the steering wheel to straight ahead position.

- After Selecting the "vehicle model" and "system", select the "SAS Calibration" on diagnostic tool vehicle selection screen.

- Remove the DTC.

- Turn off the IG switch and wait for 10 seconds or more before starting the engine. And then make sure that MDPS works properly.

Replacement

C-MDPS

- Turn the steering wheel so that the front wheels are placed in the straight ahead position.

- Turn the ignition switch OFF and disconnect the battery negative (-) cable.

- Remove the driver airbag (DAB).

(Refer to Restraint - "Driver Airbag (DAB) Module and Clock Spring")

- Remove the steering wheel.

(Refer to Steering System - "Steering wheel")

- Remove the clock spring.

(Refer to Restraint - "Driver Airbag (DAB) Module and Clock Spring")

- Remove the multifunction switch.

(Refer to Body Electrical System - "Multifunction switch")

- Remove the steering column shroud lower panel.

(Refer to Body - "Steering Column Shroud lower Panel")

- Remove the crash pad lower pannel.

(Refer to Body - "Crash Pad Lower Pannel")

- Remove the brake pedal.

(Refer to Brake System - "Brake Pedal")

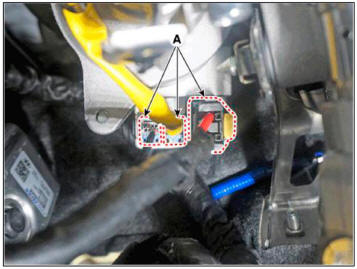

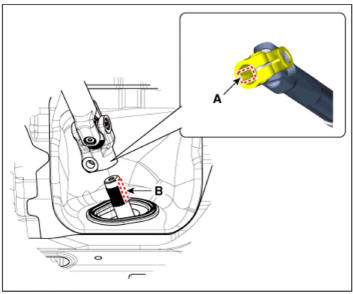

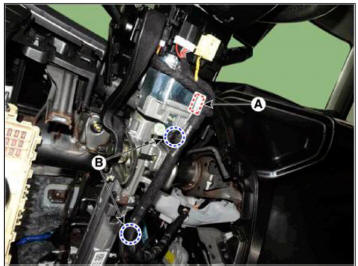

- Disconnect the MDPS connector (A. B).

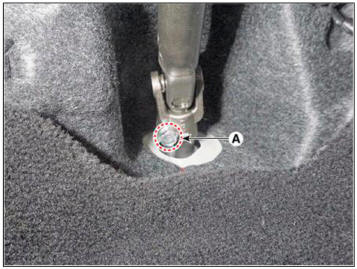

- Separate the universal joint from the steering gear box after loosening the universal joint mounting bolt (A).

Tightening torque : 53.9 - 58.8 N.m (5.5 - 6.0 kgf.m. 39.8 - 43.4 lb-ft)

WARNING

- Lock the steering wheel in the straight ahead position to prevent the damage of the clock spring inner cable.

- When mounting, securely insert the universal joint into the steering gear box pinion shaft.

- Do not reuse the universal joint bolt.

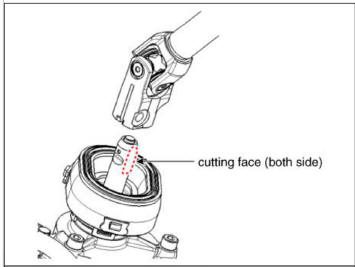

- Assemble so that pinion shaft shark pin can be inserted between the joint slots.

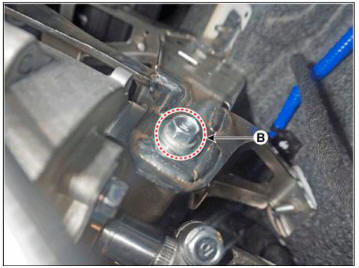

- Install by aligning the machining surface (A) of the universal

joint and the machining surface (B) of the steering

gearbox pinion shaft.

- Remove the steering column assembly after loosening the mounting nuts (A) and bolt (B).

Tightening torque :

(A): 25.0 - 29.4 N.m (2.5 - 3.0 kgf.m, 14.5 - 21.7 lb-ft)

(B): 53.9 - 58.8 N.m (5.5 - 6.0 kgf.m. 39.8 - 43.4 lb-ft)

- To install, reverse the removal procedures.

WARNING

When installing a new power pack, be sure to check whether the coupling is assembled before installing it.

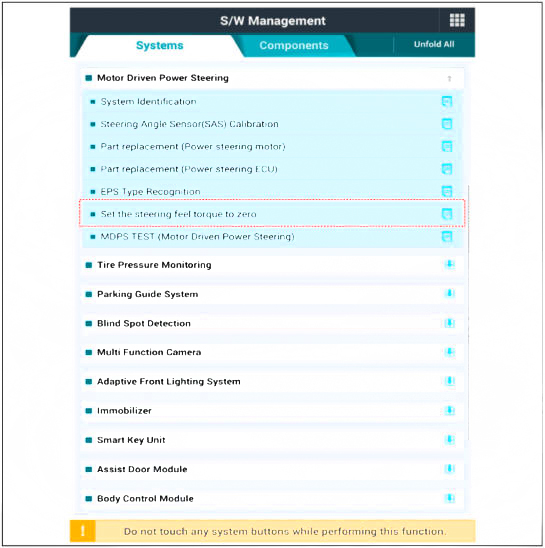

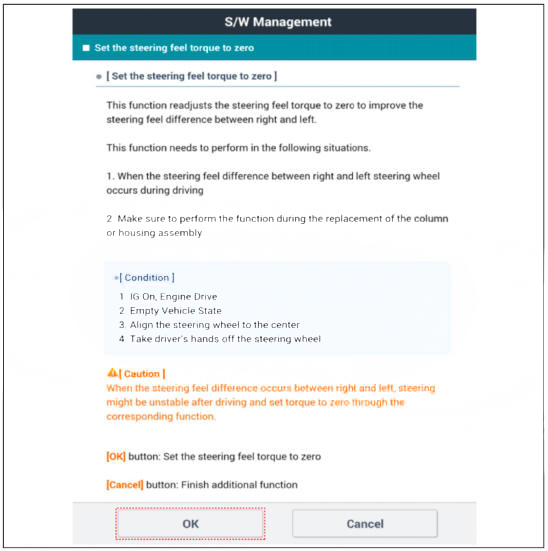

- Set the Steering angle zero point by using the diagnostic tool.

- Conduct the "EPS Type Recognition" by diagnostic tool.

(Refer to MDPS PowerPack Assembly - "Diagnosis with diagnostic tool")

- Conduct the "ASP Calibration" by diagnostic tool.

(Refer to MDPS PowerPack Assembly - "Diagnosis with diagnostic tool")

- Conduct the MDPS Performance Inspection using the diagnostic tool.

(Refer to Motor Driven Power Steering - "Repair procedures")

- Check the DTC.

- Turn off the IGN switch and wait for 20 seconds or more. Then check the operation after starting the engine.

R-MDPS

- Turn the steering wheel so that the front wheels are placed in the straight ahead position.

- Turn the ignition switch OFF and disconnect the battery negative (-) cable.

- Remove the driver airbag (DAB).

(Refer to Restraint - "Driver Airbag (DAB) Module and Clock Spring")

- Remove the steering wheel.

(Refer to Steering System - "Steering wheel")

- Remove the clock spring.

(Refer to Restraint - "Driver Airbag (DAB) Module and Clock Spring")

- Remove the multifunction switch.

(Refer to Body Electrical System - "Multifunction switch")

- Remove the steering column shroud lower panel.

(Refer to Body - "Steering Column Shroud lower Panel")

- Remove the crash pad lower pannel.

(Refer to Body - "Crash Pad Lower Pannel")

- Remove the brake pedal.

(Refer to Brake System - "Brake Pedal")

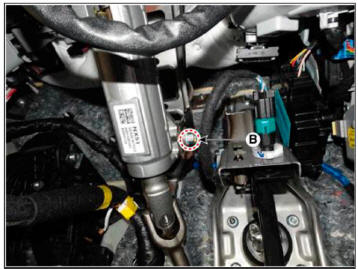

- Disconnect the electric steering column lock switch connector (A).

- Remove the fixing clip (B) from the steering column.

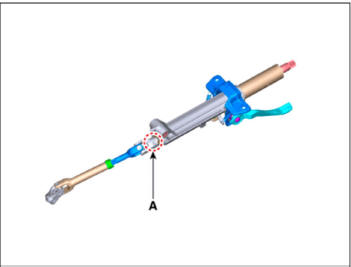

- Separate the universal joint from the steering gear box after loosening the universal joint mounting bolt (A)

Tightening torque : 53.9 - 58.8 N.m (5.5 - 6.0 kgf.m. 39.8 - 43.4 lb-ft)

WARNING

- Do not reuse the bolt.

- Lock the steering wheel in the straight ahead position to prevent the damage of the clock spring inner cable.

- Assemble so that the universal joint hole is inserted matching

the cut surface of the pinion shaft.

- Remove the MDPS assembly by loosening the mounting nuts (A) and bolt (B).

Tightening torque

(A): 25.0 - 29.4 N.m (2.5 - 3.0 kgf.m, 14.5 - 21.7 lb-ft)

(B): 53.9 - 58.8 N.m (5.5 - 6.0 kgf.m. 39.8 - 43.4 lb-ft)

- To install, reverse the removal procedures.

Disassembly

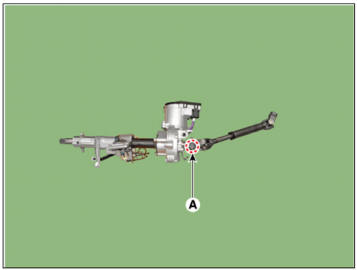

- Loosen the bolt (A) and then disconnect the universal joint assembly from the steering column assembly.

Tightening torque : 49.0 - 58.8 N.m (5.0 - 6.0 kgf.m, 39.8 - 43.4 lb-ft)

C-MDPS

R-MDPS

WARNING

Do not reuse the universal joint bolt.

- Reassembly is the reverse of the disassembly.

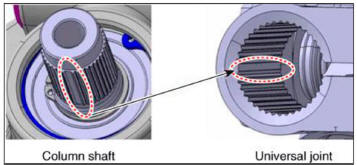

WARNING

When assembling, match the gear teeth as the below illustration.

READ NEXT:

Motor Driven Power Steering - Removal and installation

Motor Driven Power Steering - Removal and installation

WARNING

When lifting a vehicle using a lift, be careful not to damage the

lower parts of the vehicle (floor under cover, fuel filter, fuel

tank, canister).

(Refer to General Information - "Lift Point")

Loosen the front wheel nuts

Tie rod end

Tie rod end

Remove the tie rod end after loosening the nut.

Tightening torque :

49.0 - 53.9 N.m (5.0 - 5.5 kgf.m, 36.2 - 39.8 lb-ft)

WARNING

Before removing the tie rod end, note by measuring the length of the

thread or marked with paint.

Repl

SEE MORE:

Lighting System - Removal

Lighting System - Removal

Troubleshooting

Specifications

Removal

Disconnect the negative (-) battery terminal.

Remove the front bumper assembly.

(Refer to Body - "Front Bumper Assembly")

Disconnect the head lamp connector (A).

Loo

Rear wheel speed sensor - Inspection

Rear wheel speed sensor - Inspection

Inspection

Measure the output voltage between the terminal of the wheel speed

sensor and the body ground.

WARNING

In order to protect the wheel speed sensor, when measuring output

voltage, a 100Q resister must be used as shown.

C

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual