Hyundai Tucson: Transmission Control Module (TCM) Inspection Procedure

- Inspecting TCM ground circuit: Measure the resistance between the TCM

and chassis ground.

(Check the terminal connected to the chassis ground while using the back of the harness connector as the base point for TCM.)

Normal reading (resistance): Below 1

- Inspecting the TCM connector: Disconnect the TCM connector and visually inspect to see whether there is a bend on the ground terminal of the harness connector. Also visually check the connection pressure.

- If no problem is found during inspection in step 1 and step 2, then the problem is with the TCM itself. In this case, replace the TCM and inspect the vehicle again.

- Re-inspecting TCM: Install the TCM that was determined to have malfunctioned from step 3 in another vehicle. Reset the error code and then check the operation in that vehicle. If the vehicle operates without any problems, then inspect the first vehicle with the initial problem again.

Removal

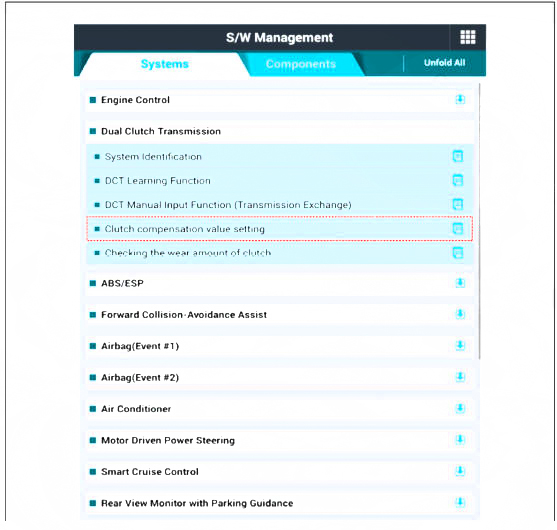

- Prior to replacing the TCM, check the TCM clutch compensation value with the diagnostic tool tool.

- Turn ignition switch OFF and disconnect the battery negative (-) terminal.

- Remove the clutch actuator assembly.

(Refer to Dual Clutch Transmission Control System - "Clutch Actuator & TCM Assembly")

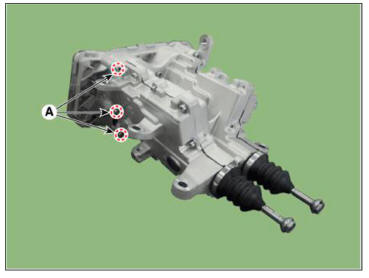

- Loosen the bolts (A) and then removing the TCM (B).

Tightenniug torque: 7.8 - 9.8 N.m (0.8 - 1.0 kgf.m. 5.8 - 7.2 lb-ft)

Installation

- To install, reverse the removal procedure.

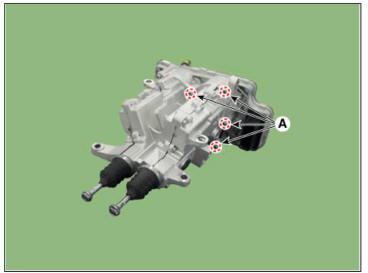

WARNING

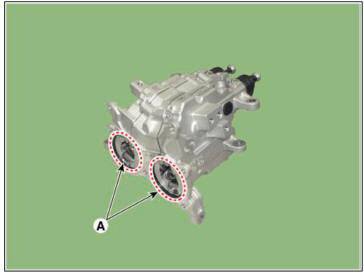

The existing O-rings (A) must be replaced with a new one. (Do not

reuse it.)

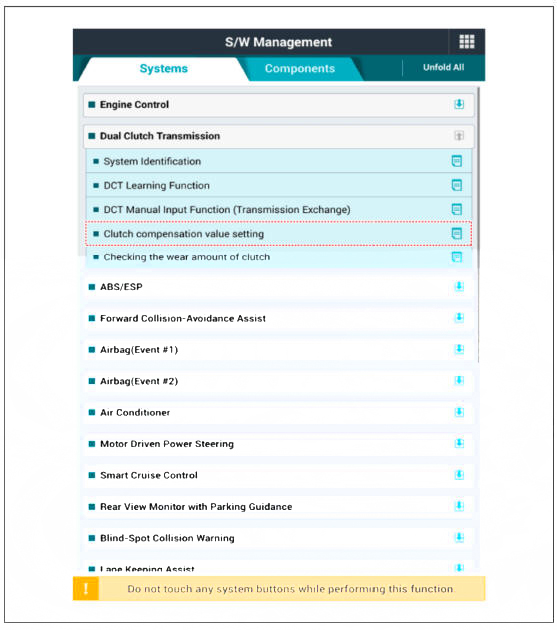

- Perform the clutch compensation value setting procedure using the diagnostic tool after replacing TCM.

WARNING

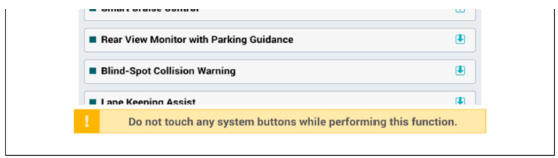

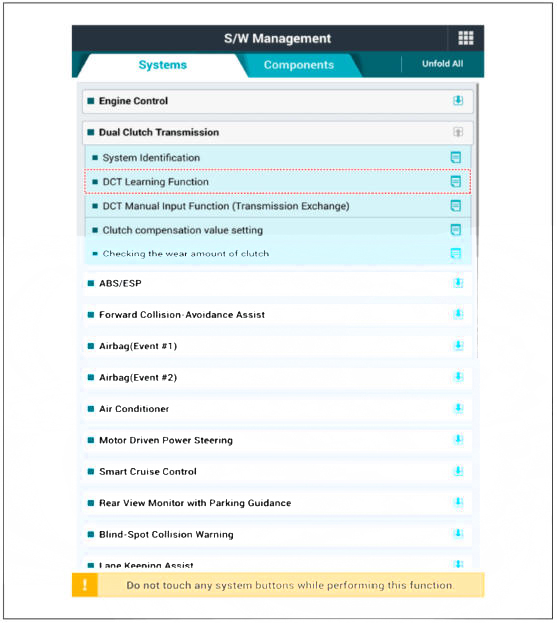

- Before performing the DCT learning procedure using diagnostic tool, perform the learning process after leaving for 5 minutes in the idle state. Because it may be a problem to operation of wear compensation device when entering the DCT learning function at battery low voltage condition.

- When performing the DCT learning function, Perform the DCT learning function twice to ensure accuracy and reliability of the clutch touch point.

- When the ignition is turned off after completing the 2 steps of the DCT learning procedure, the operation of wear compensation device will be performed. It takes up to 6 minutes for the operation of the wear compensation device to be completed, during which time it should not be started engine.

- The engine must be started after at least 6 minutes to ensure that the wear compensation device is fully operated, (keep the engine off for at least 6 minutes)

- If the engine is started while the wear compensation device is operating, sufficient operation of the wear compensation device is not possible, so the excessive operation of the wear compensation device may occur in the next engine starting cycle

- Perform the clutch touch point learning procedure using the diagnostic tool after replacing TCM

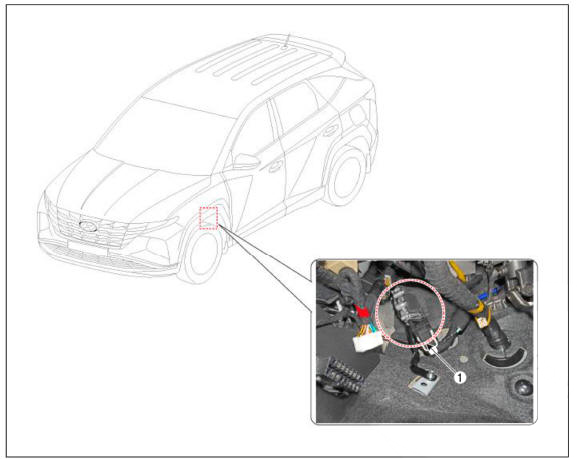

Component Location

- Shift by wire Control Unit (SCU)

Schematic Diagrams

Removal

- Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

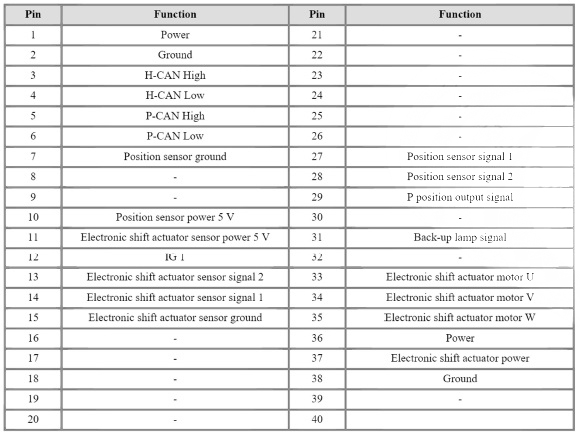

- Disconnect the SBW control unit connector (A).

- Loosen the nut and bolts and then removing the SBW control unit bracket assembly (A).

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

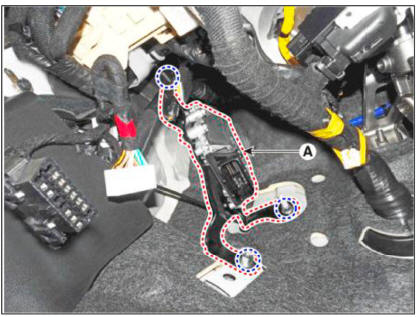

- Loosen the bolts and then removing the SBW control unit (A) from the bracket.

Tightening torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

Installation

- To install, reverse the removal procedure.

Description

- Components location : DCT (Dual Clutch Transmission)

- Function

The clutch actuator receives signals from the Transmission Control Module (TCM) and controls the clutch.

READ NEXT:

Clutch actuator assembly - Components

Clutch actuator assembly - Components

Components

Fork cover

Clutch actuator & TCM assembly

Clutch actuator assembly

O-ring

DCT control module (TCM)

Specification

Removal

Turn ignition switch OFF and disconnect the battery negative (-)

terminal.

Remove

Gear actuator assembly

Gear actuator assembly

Components

Gear actuator assembly

Specification

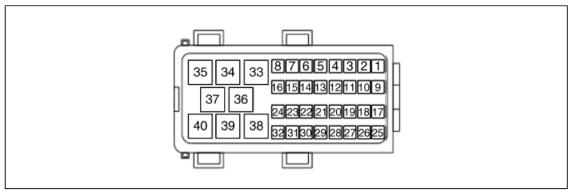

Connector and Terminal Function

Circuit Diagram

Removal

Turn ignition switch OFF and disconnect the negative (-) battery cable.

Remove the air cleaner assembly and ai

Gear actuator assembly- Installation

Gear actuator assembly- Installation

To install, reverse the removal procedure.

WARNING

Check the details below before installing the gear acmator

assembly.

1)Check that the gear acmator is placed in the "neutral" state.

2)Check the assembled state of the O-ri

SEE MORE:

Exterior Bumper Antenna

Exterior Bumper Antenna

Disconnect the negative (-) battery terminal.

Lift the vehicle.

Disconnect the antenna connector (A) from the rear bumper.

Remove the antenna (B) after loosening mounting nuts.

Buzzer

Disconnect the negative (-) battery terminal.

Heated Steering Wheel Control Module (Integrated Body Control Unit (IBU)

Heated Steering Wheel Control Module (Integrated Body Control Unit (IBU)

Turn the ignition switch OFF and disconnect the battery negative (-)

cable.

Remove the glove box.

(Refer to Body - "Glove Box")

Remove the heater control unit.

(Refer to Heating,Ventilation And Air Conditioning - "Hea

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual