Hyundai Tucson: Gear actuator assembly

Components

- Gear actuator assembly

Specification

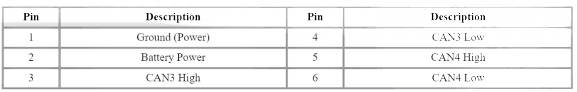

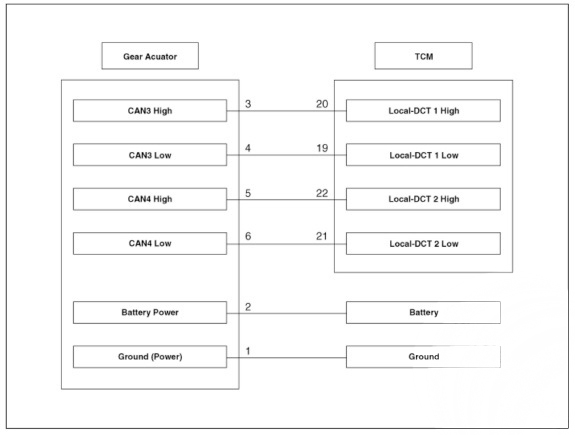

Connector and Terminal Function

Circuit Diagram

Removal

- Turn ignition switch OFF and disconnect the negative (-) battery cable.

- Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air cleaner")

- Remove the ECM.

(Refer to Engine Control / Fuel System - "Engine Control Module (ECM)")

- Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

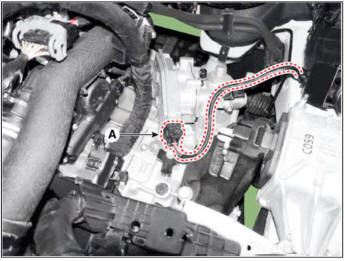

- Disconnect the gear actuator connector (A).

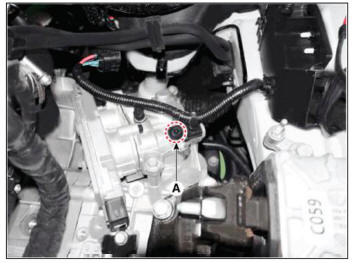

- Loosen the mounting bolts (A) and then remove the wiring bracket.

Tightening torque : 9.8- 11.8 N.m (1.0- 1.2 kgf.m. 7.2 - 8.7 lb-ft)

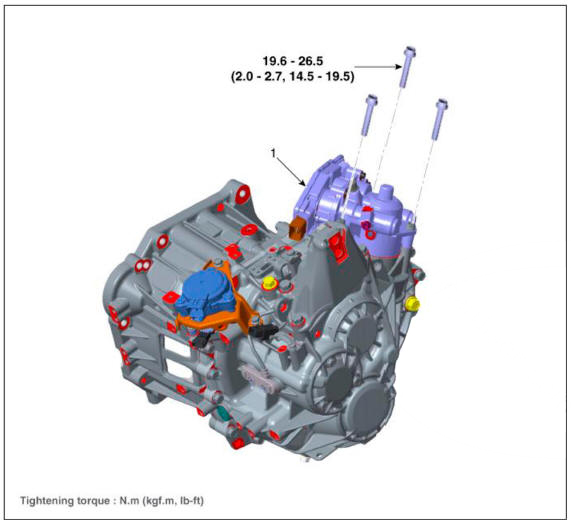

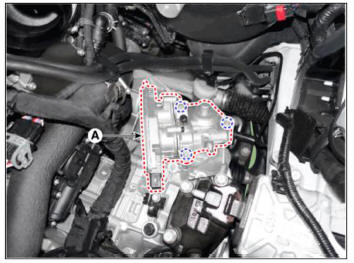

- Loosen the bolts and then removing the gear acmator (A).

Tightening torque : 19.6 - 26.5 N.m (2.0 - 2.7 kgf.m, 14.5 - 19.5 lb-ft)

READ NEXT:

Gear actuator assembly- Installation

Gear actuator assembly- Installation

To install, reverse the removal procedure.

WARNING

Check the details below before installing the gear acmator

assembly.

1)Check that the gear acmator is placed in the "neutral" state.

2)Check the assembled state of the O-ri

Input shaft speed sensor

Input shaft speed sensor

Components

Input shaft speed sensor 1 (Odd)

Input shaft speed sensor 2 (Even)

Specification

Circuit Diagram

Removal

Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

Remove the air cleaner assembly a

Input shaft speed sensor- Removal

Input shaft speed sensor- Removal

Removal

Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air cleaner")

Disconnect the electronic shift actuator connecto

SEE MORE:

Mass Air Flow Sensor (MAFS)

Mass Air Flow Sensor (MAFS)

Description

MAFS uses a hot-film type sensing element to measure the mass of intake air

entering the engine, and

send the signal to ECM.

A large amount of intake air represents acceleration or high load conditions

while a small amount of

in

Active Air Flap(AAF)

Active Air Flap(AAF)

Remove the front bumper.

(Refer to Body (Interior and Exterior) - "Front Bumper Cover")

Disconnect the active air flap connector (A).

RH

LH

Remove the active air flap (A) after loosening the mounting screws.

RH

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual