Hyundai Tucson: Input shaft speed sensor- Removal

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / DCT (Dual Clutch Transmission) System / DCT (Dual Clutch Transmission) System (SBW) / Input shaft speed sensor- Removal

Removal

- Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

- Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air cleaner")

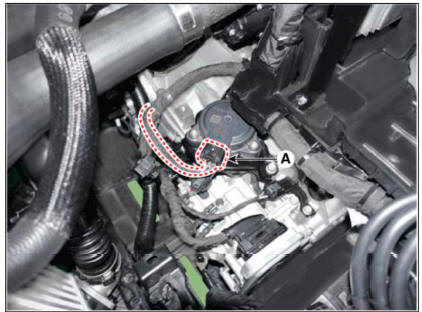

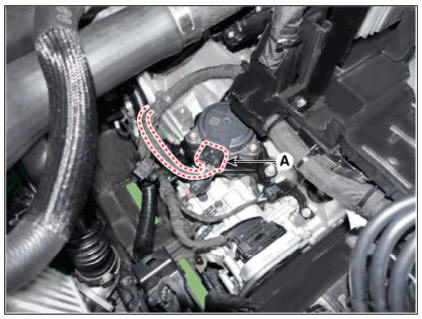

- Disconnect the electronic shift actuator connector (A).

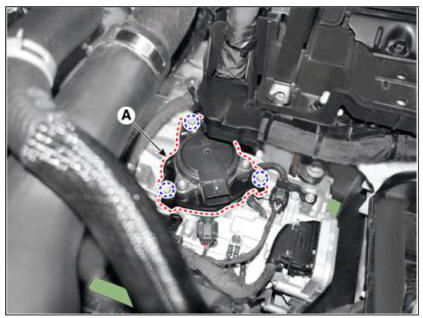

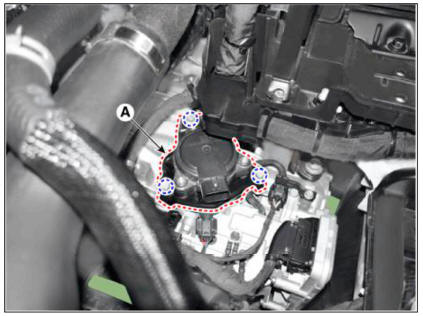

- Loosen the bolts and then removing the electronic shift actuator (A).

Tightening torque : 20.6 - 26.5 N.m (2.1 - 2.7 kgf.m, 15.2 - 19.5 lb-ft)

Installation

- To install, reverse the removal procedure.

Removal

Floor Console Assembly

Removal

- Turn ignition switch OFF and disconnect the negative (-) batteiy cable.

- Remove the console upper cover.

(Refer to Body (Interior and Exterior) - "Floor Console Assembly")

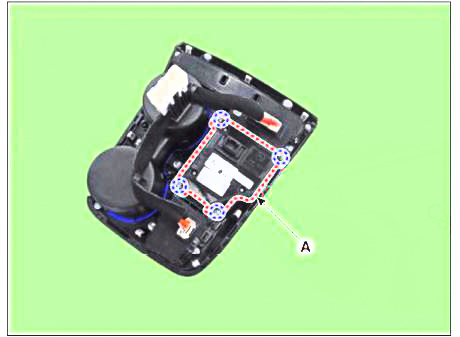

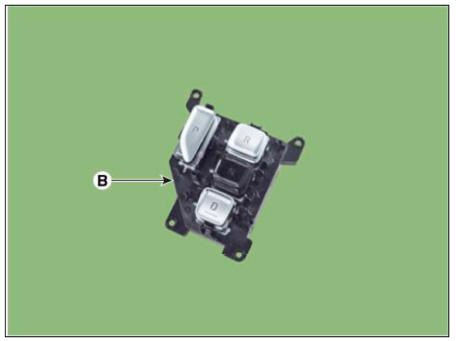

- Loosen the screw and then removing the electric shift button (A).

- Loosen the screw and then removing the upper cover (A) from electric shift button (B).

Installation

- To install, reverse the removal procedure.

Description

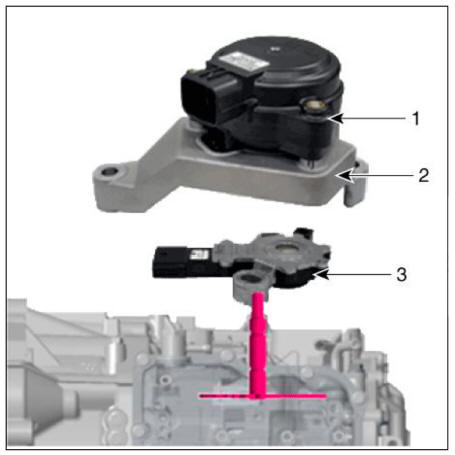

- Output position signal(P,R.N,D) by the actuator operation to the controller (SBW Control Unit_SCU).

- Electronic Shift Actuator

- Bracket

- Position sensor

Troubleshooting

Major Symptom/ Expected Cause/ Items to Check and Measures

Shock when shifting to and from D/R Motor run-up when shifting to and from D/R

- Faulty position sensor "N" setting

- Use the "N" setting jig and adjust the "N" setting.

- (Refer to "Automatic Transaxle System - Position Sensor")

- Faulty oil pressure in the valve body

- Replace valve body assembly or inspect/replace transaxle assembly

Faulty engine start Current gear not indicated in the Cluster Warning Lamp ON Engine stall while stopped Creeping not possible Auto parking release disabled

- Faulty CAN terminating resistance/circuit

- Check TCM/'battery management system module.

- Check TCM wiring connector connection.

- Faulty position sensor circuit fuse

- Check fuse and junction box terminal, and repair.

- Faulty position sensor wiring connector

- Check for foreign substance in the wiring connector, and check for gap on the terminal.

- Check sealing on unused pin, and check for corrosion on the terminal.

- Faulty reverse lamp circuit

- Check reverse lamp ground, and reassemble if necessary.

- Faulty position sensor wiring ground

- Check wiring ground, and reassemble if necessary.

- Position sensor faulty code

- Inspect in accordance with the inspection flow, then replace position sensor if necessary.

Specification

Removal

WARNING

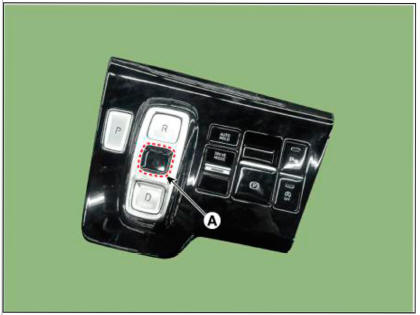

- Before removal, press the brake pedal while the ignition switch

is ON and press the N button (A) for a

long time to position it in the N position, then remove the battery (-)

terminal.

- Turn ignition switch OFF and disconnect the battery negative (-) terminal.

- Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air cleaner")

- Disconnect the electronic shift actuator connector (A).

- Loosen the bolts and then removing the electronic shift actuator (A).

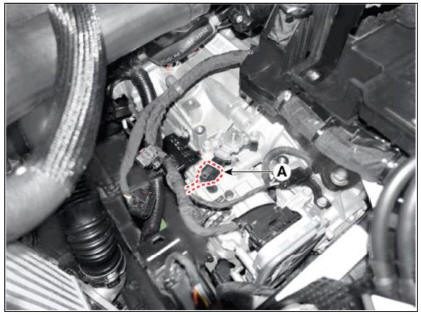

- Disconnect the position sensor connector (A).

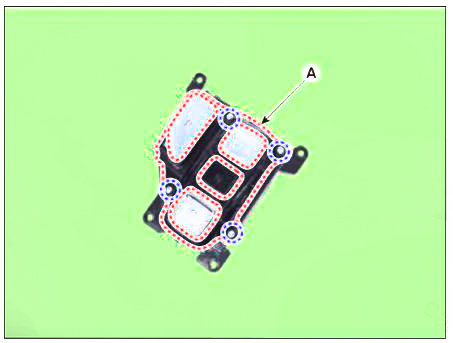

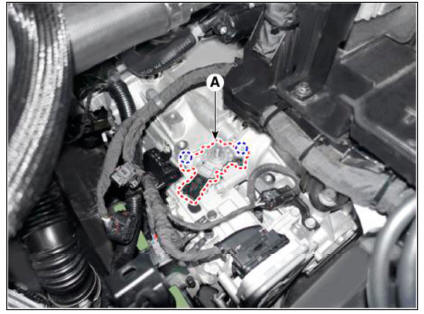

- Loosen the bolts and then removing the position sensor (A).

READ NEXT:

Input shaft speed sensor- Installation

Input shaft speed sensor- Installation

Installation

Check that the shaft is in the "N" position.

Install the position sensor (A) and then lightly tighten the bolts.

Install the position sensor "N" fixing SST(No.:09430-2Cl 10).

Tighten position

Clutch fork and clutch bearing

Clutch fork and clutch bearing

Components

Clutch housing

Engagement bearing 2 (Even)

Egnagement bearing 1 (Odd)

Engagement bearing sleeve

Clutch engagement fork

Removal

Remove the dual clutch transmission from the vehicle

(Refer to Dual Clutch Transmissio

SEE MORE:

Rear Cross-Traffic Collision Warning (RCCW)

Rear Cross-Traffic Collision Warning (RCCW)

RCCW activating conditions

(1) User Setting Menu (USM): Select 'Driver Assist Parking Safety' - 'Rear Cross-Traffic Safety'

(2) Shift lever position: R

(3) Vehicle speed: 0 ~ 8 km/h

(4) Speed of opponent vehicle: 5 km h or faster

Body Control Module Controls The Followings

Body Control Module Controls The Followings

Description

Body Control Module Controls The Followings

Wiper & Washer Control

Defroster Control

Driving Control

Tailgate Control

Window Control

Interior Control

Exterior Control

Panic alarm Control

MTS

Flasher output Contr

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual