Hyundai Tucson: Electrical Circuit Inspection Procedure

- Check Open Circuit

- Procedures for Open Circuit

- Continuity Check

- Voltage Check

If an open circuit occurs (as seen in FIG. 1), it can be found by performing Step 2 (Continuity Check Method) or Step 3 (Voltage Check Method) as shown below.

- Continuity Check Method

WARNING

When measuring for resistance, lightly shake the wire harness above and below or from side to side.

Specification (Resistance)

1 or less

→ Normal Circuit

1M

or less

→ Normal Circuit

1M or Higher

→ Open Circuit

or Higher

→ Open Circuit

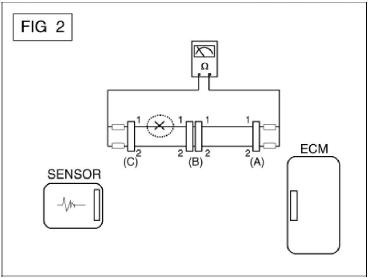

a.Disconnect connectors (A), (C) and measure resistance between connector (A) and (C) as shown in FIG. 2.

In FIG.2. the measured resistance of line 1 and 2 is higher than 1M and below 1

and below 1 respectively.

Specifically the open

circuit is line 1 (Line 2 is normal). To find exact break point, check sub line

of line 1 as described in next step.

respectively.

Specifically the open

circuit is line 1 (Line 2 is normal). To find exact break point, check sub line

of line 1 as described in next step.

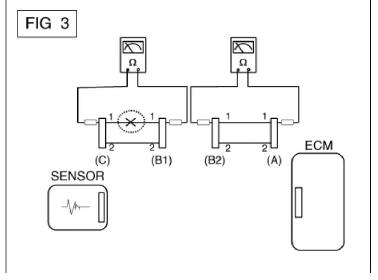

b.Disconnect connector (B), and measure for resistance between connector (C) and (B1) and between (B2) and (A) as shown in FIG. 3.

In this case the measured resistance between connector (C) and (B1) is higher than 1MQ and the open circuit is between terminal 1 of connector (C) and terminal 1 of connector (B1).

- Voltage Check Method

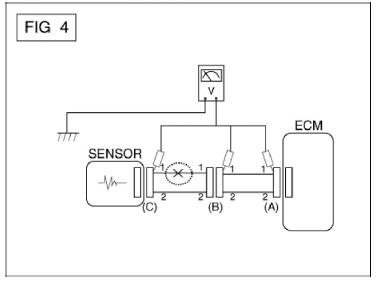

a.With each connector still connected, measure the voltage between the chassis ground and terminal 1 of each connectors (A), (B) and (C) as shown in FIG. 4.

The measured voltage of each connector is 5V, 5V and 0V respectively. So the open circuit is between connector (C) and (B).

Check Short Circuit

- Test Method for Short to Ground Circuit

- Continuity Check with Chassis Ground

If short to ground circuit occurs as shown in FIG. 5, the broken point can be found by performing Step 2 (Continuity Check Method with Chassis Ground) as shown below.

- Continuity Check Method (with Chassis Ground)

WARNING

Lightly shake the wire harness above and below, or from side to side when measuring the resistance.

Specification (Resistance)

1 or less

→ Short to Ground Circuit

1M

or less

→ Short to Ground Circuit

1M or Higher

→ Normal Circuit

or Higher

→ Normal Circuit

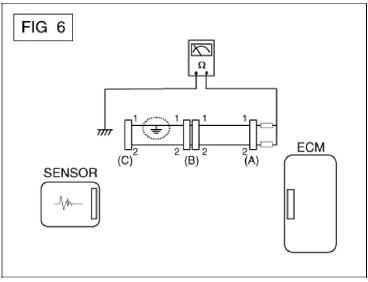

a. Disconnect connectors (A), (C) and measure for resistance between connector (A) and Chassis Ground as shown in FIG. 6.

The measured resistance of line 1 and 2 in this example is below 1 and higher than 1M

and higher than 1M respectively.

Specifically the

short to ground circuit is line 1 (Line 2 is normal). To find exact broken point,

check the sub line of line 1 as described

in the following step.

respectively.

Specifically the

short to ground circuit is line 1 (Line 2 is normal). To find exact broken point,

check the sub line of line 1 as described

in the following step.

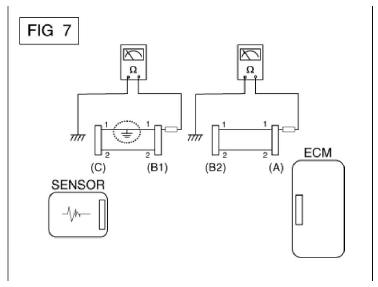

b. Disconnect connector (B), and measure the resistance between connector (A) and chassis ground, and between (B1) and chassis ground as shown in FIG. 7.

The measured resistance between connector (B1) and chassis ground is 1

or less. The short to ground

circuit is

between terminal 1 of connector (C) and terminal 1 of connector (B1).

or less. The short to ground

circuit is

between terminal 1 of connector (C) and terminal 1 of connector (B1).

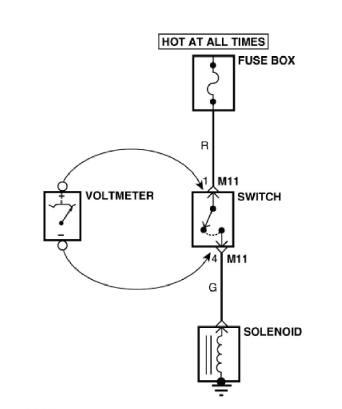

Testing For Voltage Drop

This test checks for voltage drop along a wire, or through a connection orswitch.

- Connect the positive lead of a voltmeter to the end of the wire (or to the side of the connector or switch) closest to the battery.

- Connect the negative lead to the other end of the wire. (or the other side of the connector or switch)

- Operate the circuit.

- The voltmeter will show the difference in voltage between the two points. A difference, or drop of more than 0.1 volts (50mV in 5 V circuits), may indicate a problem. Check the circuit for loose or dirty connections.

READ NEXT:

Symptom Troubleshooting Guide Chart

Symptom Troubleshooting Guide Chart

Specifications

Fuel Delivery System

Sensors

Manifold Absolute Pressure Sensor (MAPS)

Type : Piezo-Resistive Pressure

Sensor type

Specification

Intake Air Temperature Sensor (IATS)

Type : Termistor type

Specific

Engine Control - Fuel System - Description and Operation

Engine Control - Fuel System - Description and Operation

Description

If the Gasoline Engine Control system components (sensors, ECM, injector, etc.)

fail, interruption to the fuel supply or failure

to supply the proper amount of fuel for various engine operating conditions will

result. The following

Components and Components Location

Components and Components Location

Components Location

Engine Control Module (ECM)

Mass Air Flow Sensor (MAFS)

Manifold Absolute Pressure Sensor (MAPS)

Intake Air Temperature Sensor (IATS)

Boost Pressure Sensor (BPS)

Engine Coolant Temperature Sensor (E

SEE MORE:

Rear Glass Defogger

Rear Glass Defogger

Inspection

Wrap tin foil around the end of the voltmeter test lead to prevent damaging

the heater line. Apply

finger pressure on the tin foil, moving the tin foil along the grid line to

check for open circuits.

Turn on the defogger swit

Lane Keeping Assist Malfunction and Limitations

Lane Keeping Assist Malfunction and Limitations

Lane Keeping Assist malfunction

When Lane Keeping Assist is not working

properly, the 'Check Lane Keeping Assist

(LKA) system' warning message will

appear and the yellow indicator

light will illuminate on the cluster. If this

occurs, have

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual