Hyundai Tucson: Initializing Method of the Safety Power Window

- Initializing of Battery Connection

When the battery power is removed for over 5 minutes, safety power window switch need the initializing.

(1) Power window operation before initializing

- Manual-Up/Down function is available

- Auto-Up function is not available (When holding the auto-up/down switch, window is operated as a manual-up/down.)

(2) Initializing method

Close the window in window open position, and holding the switch in window full close position over the 0.2 second.

(If start the closing the window in window full close position, initializing could be failed.)

(3) If initialize the safety power window in jamming status, could occur below conditions.

- Safety function is not available

- Initializing of fail safe mode

(1) If the window moved by compulsion and motor have a problem, power window switch could be entering the fail safe mode for user's safety.

(2) Power window operation in fail mode

- Auto/Manual-Down function is available

- Auto/Manual-Up function is not available

(When auto/manual-up is operated, window is rising 20mm and is stopped the moving.)

Inspection

Front Power Window Motor

- Disconnect the negative (-) battery terminal.

- Remove the front door trim.

(Refer to Body - "Front Door Trim")

- Disconnect the motor connector from the motor.

- Connect the motor terminals directly to battery voltage (12V) and check that the motor operates smoothly. Next, reverse the polarity and check that the motor operates smoothly in the reverse direction. If the operation is abnormal, replace the motor.

Safety Window Motor

- Connect the motor terminals directly to battery voltage (12V) and check that the motor operates smoothly. Next, reverse the polarity and check that the motor operates smoothly in the reverse direction. If the operation is abnormal, replace the motor.

Standard Window Motor

Rear Power Window Motor

- Disconnect the negative (-) battery terminal.

- Remove the rear door trim.

(Refer to Body - "Rear Door Trim")

- Disconnect the motor connector from the motor.

- Connect the motor terminals directly to battery voltage (12V) and check that the motor operates smoothly. Next, reverse the polarity and check that the motor operates smoothly in the reverse direction. If the operation is abnormal, replace the motor.

Safety Window Motor

- Connect the motor terminals directly to battery voltage (12V) and check that the motor operates smoothly. Next, reverse the polarity and check that the motor operates smoothly in the reverse direction. If the operation is abnormal, replace the motor.

Standard Window motor

Driver Power Window Main Switch

Removal

- Disconnect the negative (-) battery terminal.

- Remove the front door trim.

(Refer to Body - "Front Door Trim")

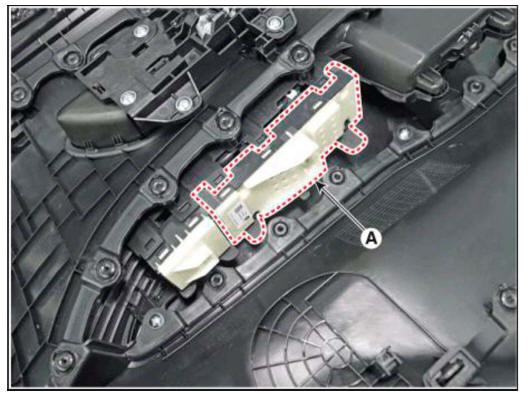

- Remove the power window main switch assembly (A).

Assist Rear Power Window Switch

- Disconnect the negative (-) battery terminal.

- Remove the door trim.

(Refer to Body - "Front Door Trim") (Refer to Body - "Rear Door Trim")

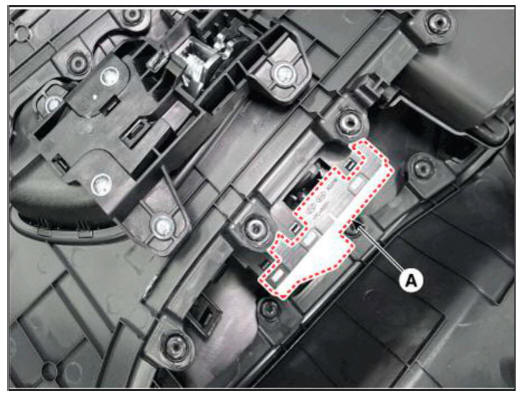

- Remove the assist/rear power window switch assembly (A).

Installation

Power Window Switch

- Install the power window switch assembly.

- Install the front/rear door trim after connecting the connector.

- Connect the negative (-) battery terminal.

Inspection

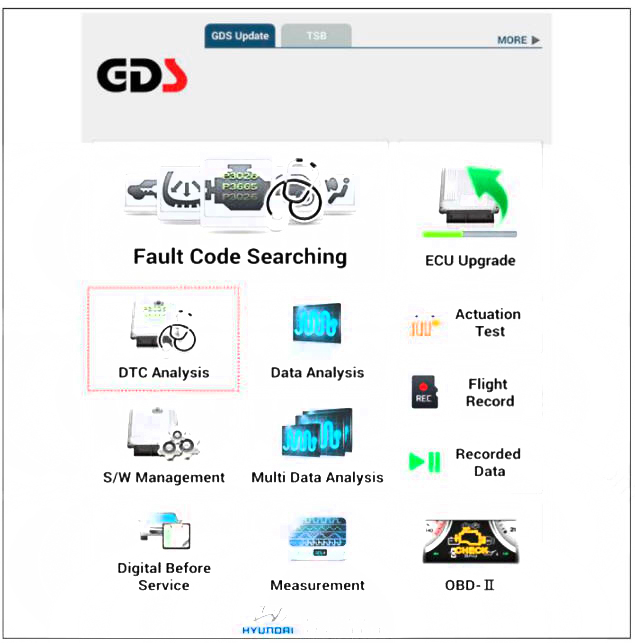

Diagnosis with diagnostic tool

- In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system (diagnostic tool).

The diagnostic system (diagnostic tool) provides the following information.

(1) Fault Code Searching : Checking failure and code number (DTC)

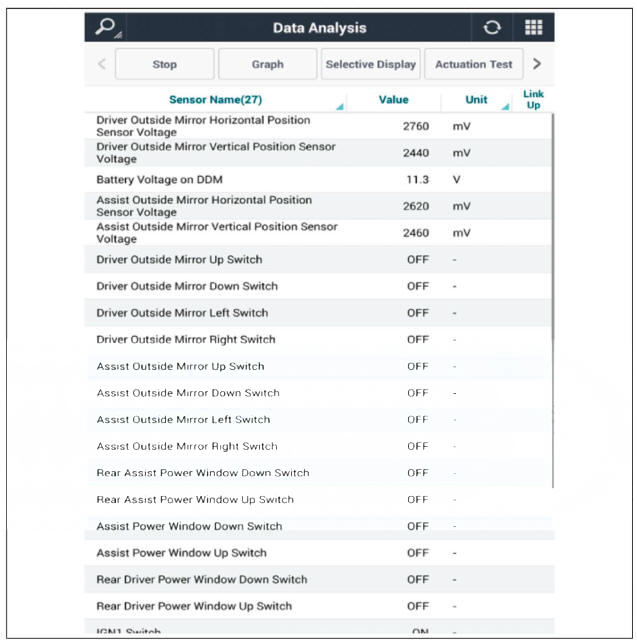

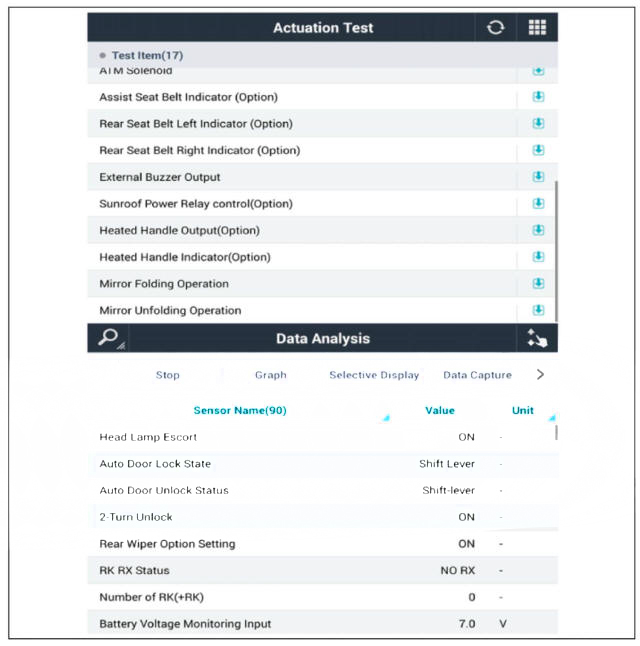

(2) Data Analysis : Checking the system input/output data state

(3) Actuation test: Checking the system operation condition

(4) S/W Management: Controlling other features including system option setting and zero point adjustment

- If diagnose the vehicle by diagnostic tool, select "DTC Analysis" and "Vehicle".

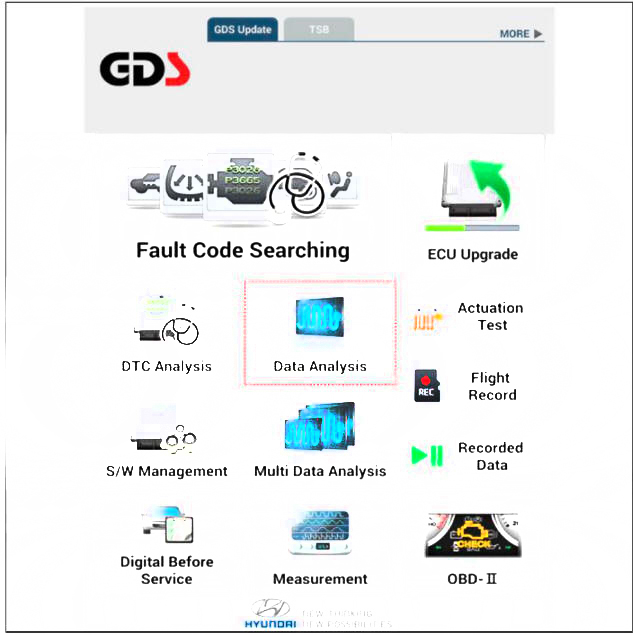

- Select the 'Data Analysis' and 'Car model'.

- Select the 'DDM' to search the current state of the input/output data.

- To forcibly actuate the input value of the module to be checked, select option 'Actuation Test'.

READ NEXT:

Rear Glass Defogger

Rear Glass Defogger

Inspection

Wrap tin foil around the end of the voltmeter test lead to prevent damaging

the heater line. Apply

finger pressure on the tin foil, moving the tin foil along the grid line to

check for open circuits.

Turn on the defogger swit

Tailgate Position And Direction

Tailgate Position And Direction

Description

Power tailgate is an electro-mechanical system designed to provide power

opening and closing of the tailgate through the

push of a button of a remote key (fob), console switch, inner switch or an

outside handle switch of the tailgat

SEE MORE:

ICU (Integrated Central Control Unit)

ICU (Integrated Central Control Unit)

Dscription and Operation

ICU (Integrated Central Control Unit) is an integrated model of smart

junction block and central gateway.

It performs the function of conventional "Smart junction block" and the function

of communication med

Rear door outside handle

Rear door outside handle

Component Location

Rear door outside handle

Replacement

Rear Door Outside Handle Assembly

WARNING

When removing with a flat-tip screwdriver or remover, wrap

protective tape around the tools to prevent

damage to components.

Put

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual