Hyundai Tucson: Electric WGT Control Actuator- Installation

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / Engine Control - Fuel System / Electric WGT Control Actuator / Electric WGT Control Actuator- Installation

WARNING

- When replacing the Electric WGT Control Actuator, perform the rod adjustment procedure.

- When install the electric WGT control actuator, do not reuse a C-Ring.

- Install in the reverse order of removal.

Adjustment

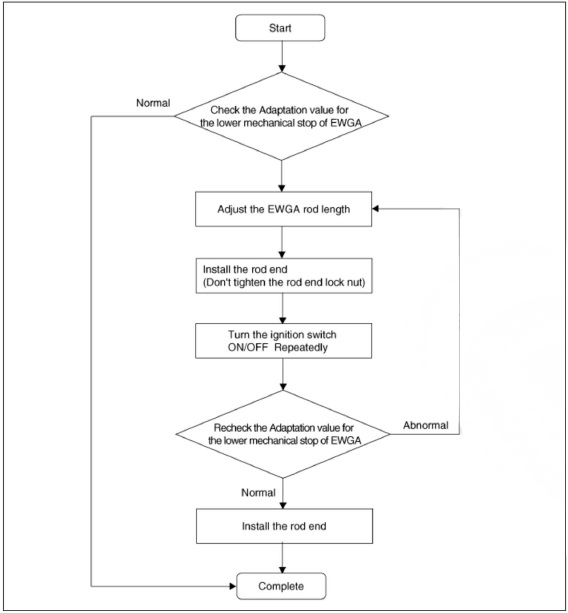

Rod Adjustment Procedure Flowchart

- Check that the waste gate turbo charger is coolenough to work.

WARNING

- Use an electric fan to cool down fast.

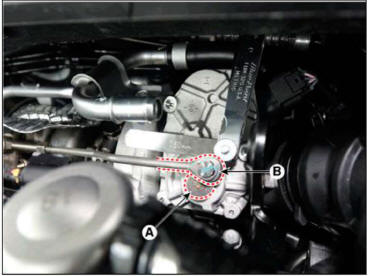

- The cooling part (A) and the wind direction (B) areas follows.

- Turn the ignition switch to OFF position.

- Connect the diagnostic tool to DLC connector (16pin) under the driver side instrument panel.

- Turn the ignition switch ON.

WARNING

Do not start the engine.

- Select VIN or Vehicle on the initial screen.

- Enter "Engine Control" menu after slelecting vehicleinformation (Vehicle model. Model year. Engine type)or entering the VIN number.

- Select the "Current Data".

- Without starting the engine, repeatedly turn theignition ON for 5

seconds and OFF for 5 seconds.and then check the

"Adaptation value for lowmechanical stop of EWGA" on the diagnostic tool.

Repeat this step until the amount of difference in theadaptation value from the previous cycle is below 0.05 V.

WARNING

Do not start the engine. This is a crucial step toread the correct adaptation value.

- Check that "Adaptation value for the lower mechanical stop of EWGA" is within the specified voltage value.

Voltage : 3.5 - 3.7V

- If the measured voltage value is not within the specified voltage value, ad just the EWGA rodlength. Otherwise, no further procedure is required.

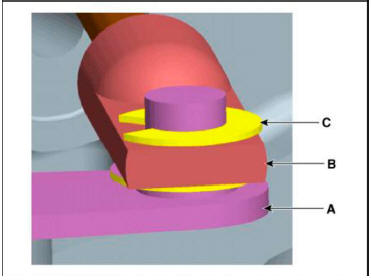

(1) Loosen the rod end lock nut (B) and remove the C-ring (A).

(2) Adjust the rod end part (C) by rotating it clockwise (D) or counterclockwise (E) to satisfy the specification.

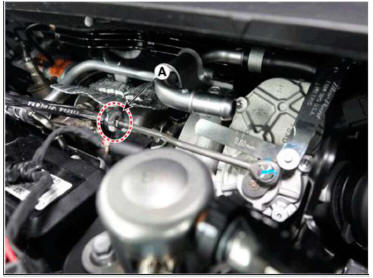

- Install the rod end (B) to the turbocharger lever (A) temporarily. Do not tighten the rod end lock nut (C) and C-ring (D).

- Check the "Adaptation value for the lower mechanical stop of EWGA" after selecting "Current Data" menu. Turn the ignition switch ON/OFF repeatedly until the changing value of the "Adaptation value for the lower mechanical stop of EWGA" is within 0.05V.

WARNING

Turn the ignition switch ON/OFF. But hold 5 seconds at each IG ON or OFF state.

- If the measured voltage value is not within the specified voltage value, repeat procedures 9 - 1 2 until the voltage value is within the specified voltage value.

- If it is within the specified voltage value, install the rod end to the turbocharger lever.

(1) Install the rod end (B) to the turbocharger lever (A) temporarily.

(2) Fix the C-ring (C).

- Install the 0.6mm filler gauge between EWGA lever (A) and rod end (B).

- Tighten the lock nut (A).

READ NEXT:

RCV Control Solenoid Valve

RCV Control Solenoid Valve

Description

RCV (Recirculation Valve) Control Solenoid Valve is installed on the

intercooler inlet pipe and

operates the RCV actuator which controls the by-pass passage of the turbocharger

compressor.When

the throttle is closed, while the engi

Electric Exhaust Gas Re-circulation (EEGR) Control Valve

Electric Exhaust Gas Re-circulation (EEGR) Control Valve

Description

The Electric EGR Control Valve is installed in between the EGR cooler and the

exhaust line and is a

solenoid valve. This valve controls EGR (Exhaust Gas Recirculation) amount by

the ECM's duty

control signal depending on engine

Integrated Thermal Management Module (ITM)

Integrated Thermal Management Module (ITM)

Description

Integrated Thermal Management Module (ITM) is a device that controls the

coolant flow rate according to coolant

temperature. At initial startup, the ITM quickly warms up the engine by

controlling the flow of the coolant and this fas

SEE MORE:

Timing System - Replacement

Timing System - Replacement

Components

Variable force solenoid valves

Timing chain cover

Cam to cam guide

Timing chain

Timing chain tensioner arm

Timing chain tensioner arm

Timing chain tensioner

Crankshaft sprocket

Oil pump chain

Oil pump chain tensio

High Pressure Fuel Line- Removal

High Pressure Fuel Line- Removal

WARNING

In case of removing the high pressure fuel pump, high pressure fuel

pipe, delivery pipe, and injector,

there may be injury caused by leakage of the high pressure fuel. So don't do any

repair work right after

engine stops.

Relea

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual