Hyundai Tucson: Differential Carrier Assembly - Reassembly

Reassembly

Pinion drive gear assembly

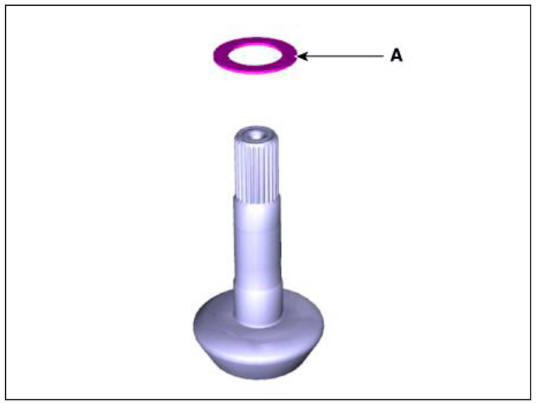

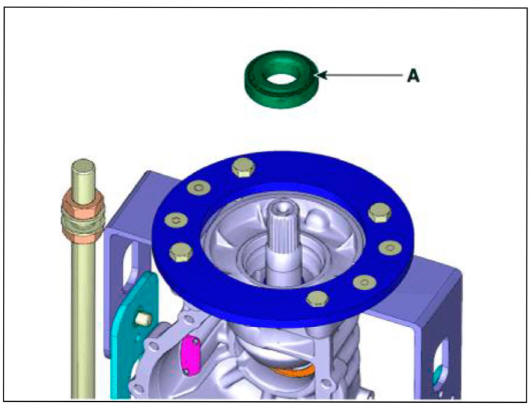

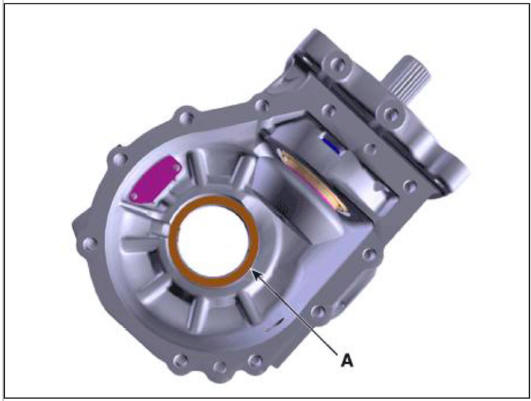

- Install the inner pinion bearing adjustment shim (A) 011 the pinion drive gear assembly.

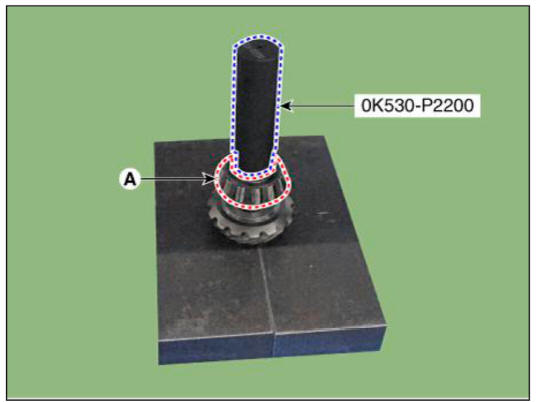

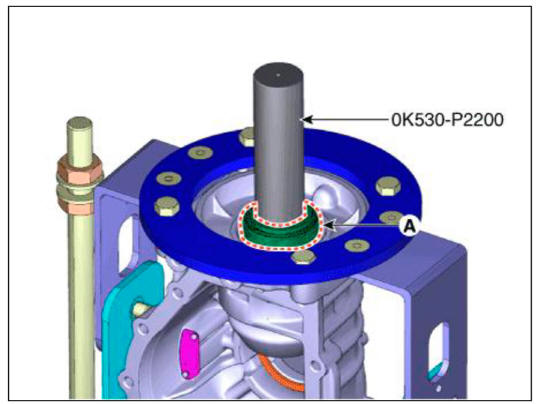

- Install the inner pinion bearing (A) on the pinion drive gear using SST (0K530-P2200) and press.

WARNING

Do not reuse the removed bearing.

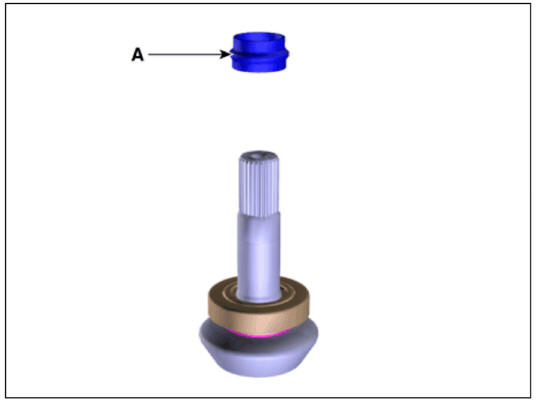

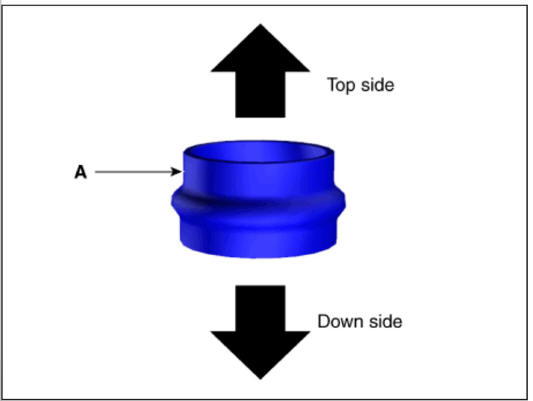

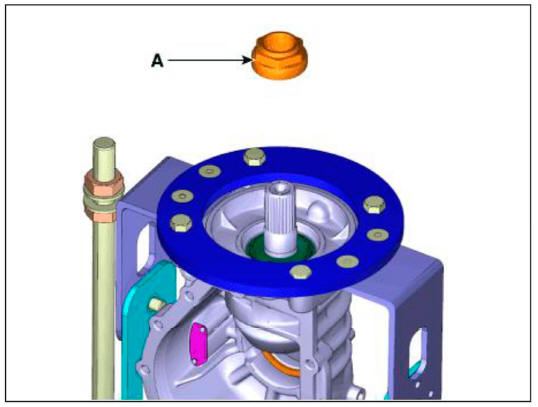

- Install the spacer (A) in the pinion drive gear assembly.

WARNING

When installing, make sure the spacer (A) is in the top side

direction.

Differential gear assembly

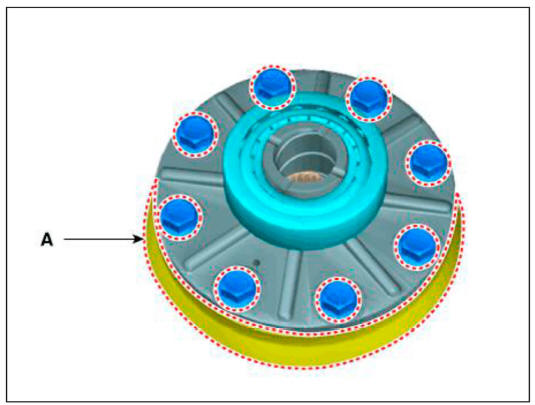

- Install the ring gear (A) on the gear carrier.

Tightening torque : 78.4 - 88.2 N m (8.0 - 9.0 kgf-m, 57.8 - 65.0 lb ft)

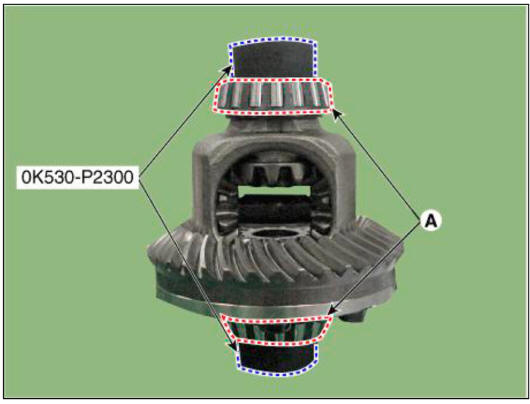

- Install the differential gear bearings (A) on both sides using the SST (0K530-P2300) and press.

WARNING

Do not reuse the removed bearing.

Differential carrier case

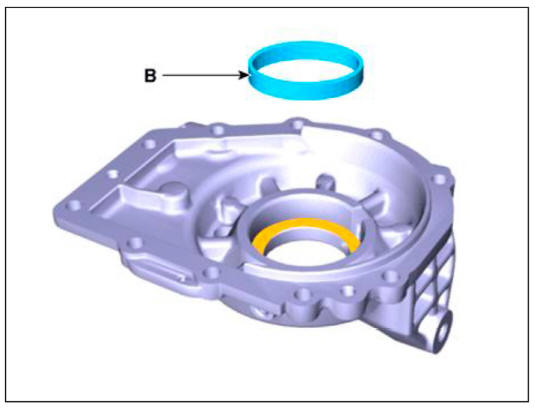

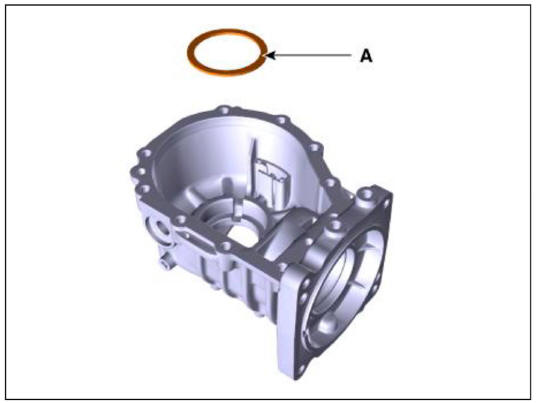

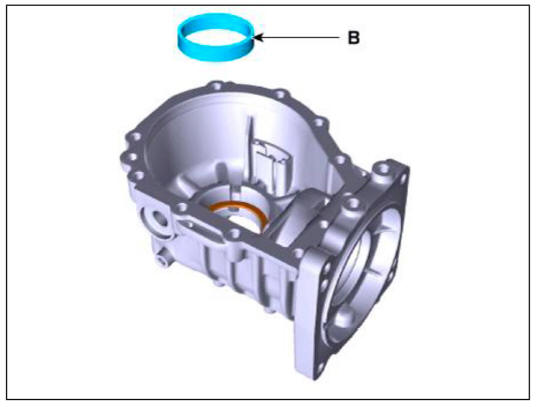

- Install the differential carrier case side cover bearing adjustment shim (A) and race (B).

- Install the differential carrier case side bearing adjustment shim (A) and race (B).

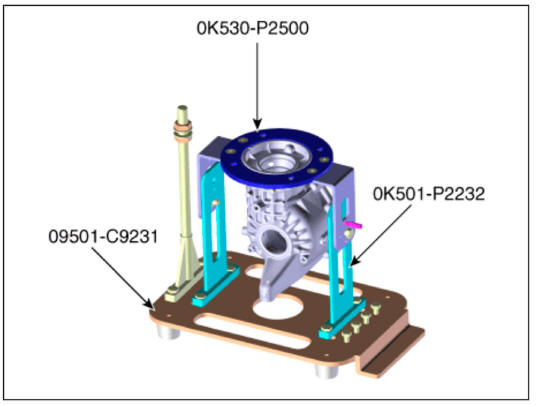

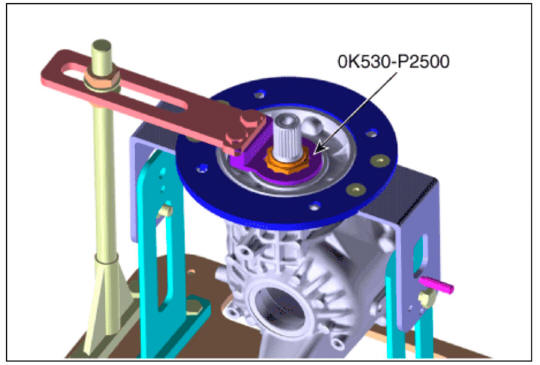

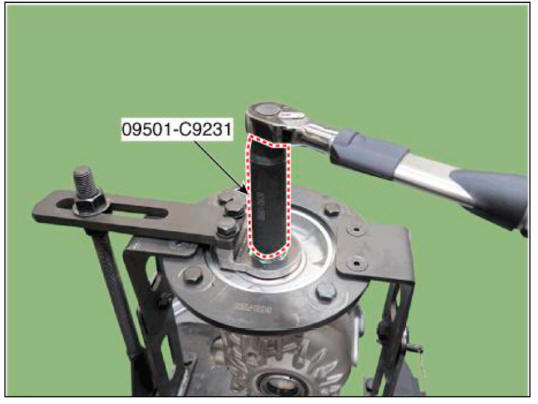

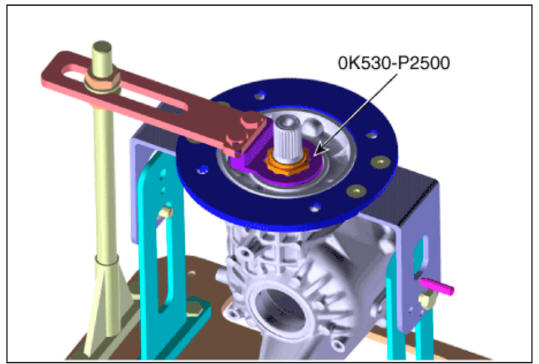

- Hold the differential carrier assembly using the SST (09501-C9231, 0K530-P2500, 0K501-P2232).

- Install the outer, inner pinion bearing race using SST (0Sb01-C9340).

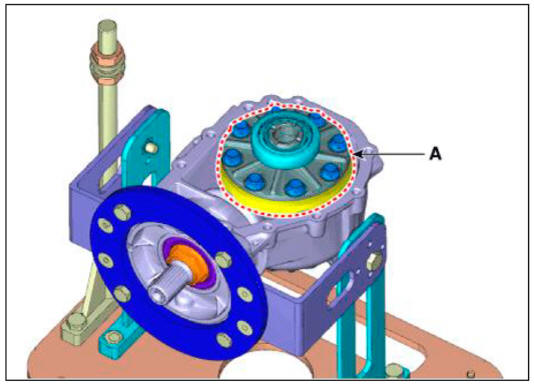

WARNING

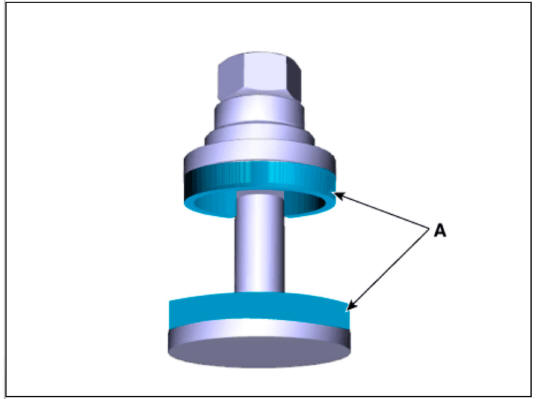

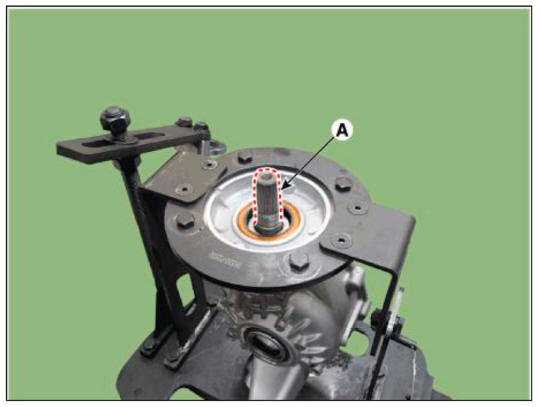

When installing, attach the race (A) with

a special tool as follows.

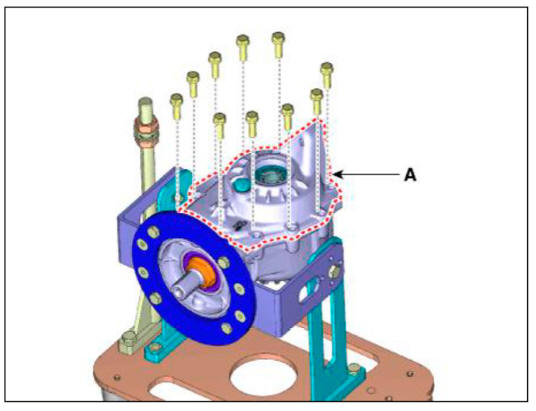

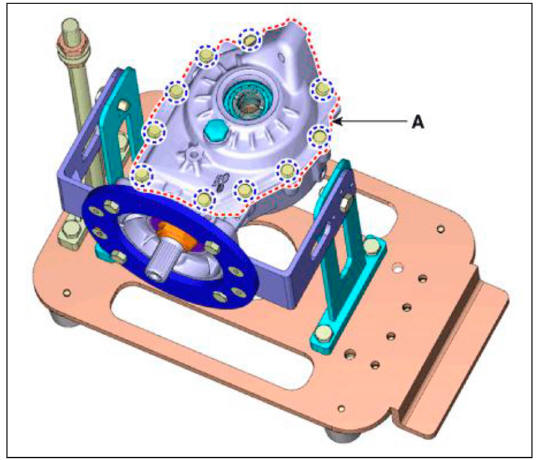

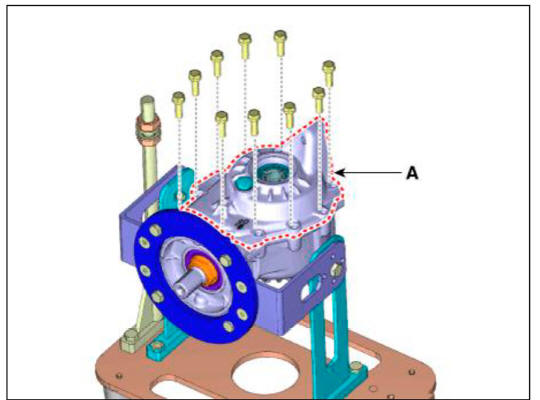

- Install the pinion drive gear assembly (A).

- Install outer pinion bearing (A) on pinion gear assembly.

WARNING

Do not reuse the removed bearing.

- Place the SST (0K530-P2200) on the pinion gear spline side and press the bearing (A) of the until the thread can engages the lock nut.

- Pre-tighten the pinion lock nut (A) to the thread 011 the side of the pinion gear spline.

WARNING

When you installing lock nut (A), replace lock nut with a new one.

- Fix the lock nut using the SST (0K530-P2500).

- Tighten the pinion gear lock nut using SST (09501-C9231) to press the outer bearing.

- Remove the SST (0K530-P2500).

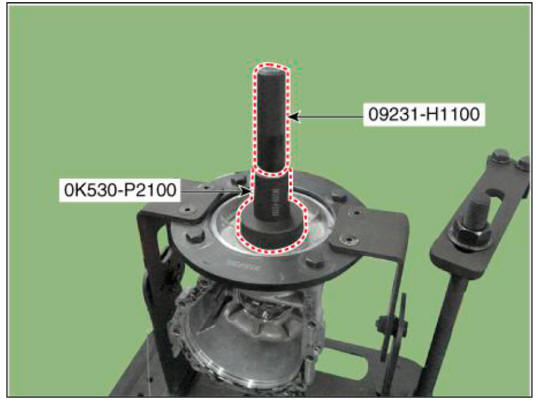

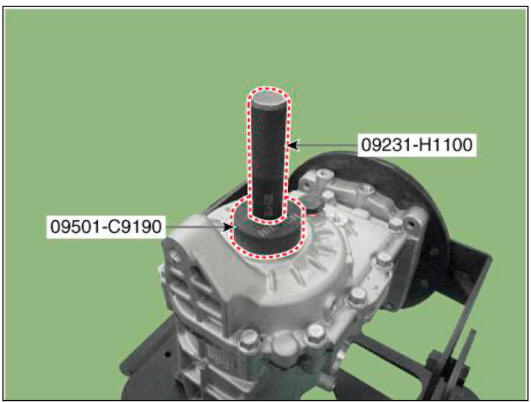

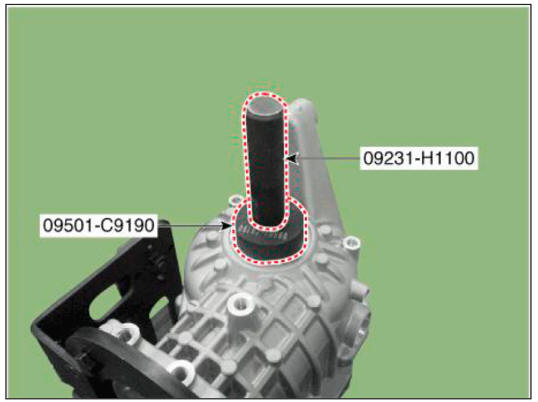

- Press the pinion oil seal using SST (0K530-P2100, 09231-H1100).

WARNING

- Make sure that the gap between the differential carrier case and the pinion oil seal is 0 - 0.5 mm.

- When installing oil seal, replace oil seal with a new one.

- Install the differential gear assembly (A) in the differential carrier case.

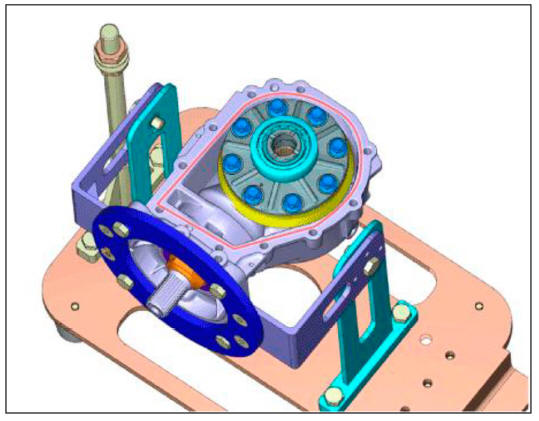

- Install the differential carrier case side cover (A).

Tightening torque : 39.2 - 49.0 N m (4.0 - 5.0 kgf rn, 28.9 - 36.1 lb ft)

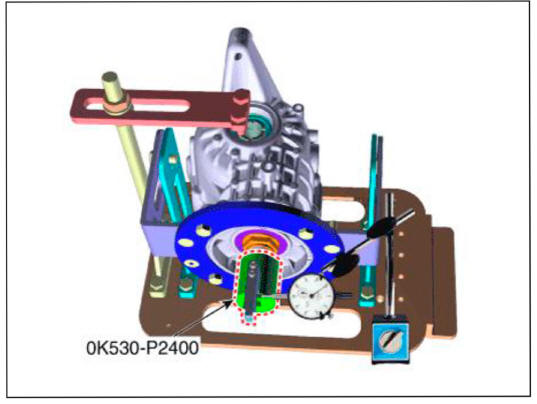

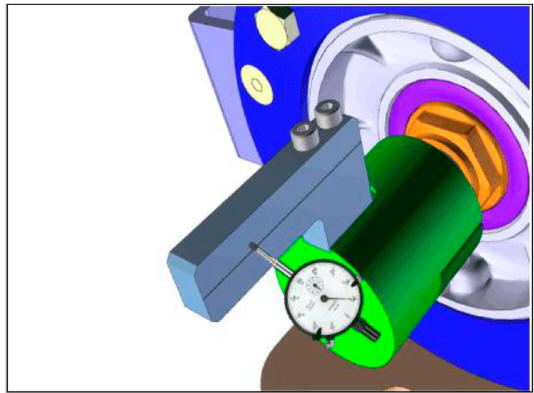

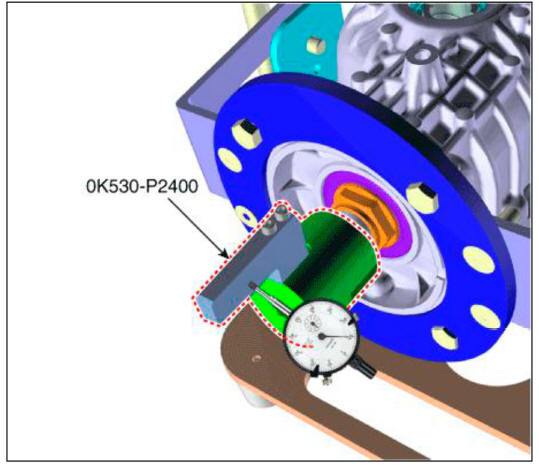

- Install SST (0K530-P2400) on the pinion drive gear spline side and set the dial gauge on the case.

WARNING

- After setting the dial gauge on the gear to be measured, adjust the dial gauge to zero.

- Secure the dial gauge to the housing to prevent it from moving or shaking.

- When measuring, be care fill that the dial gauge or jig does not interfere with the gear.

- Make the measuring surface part and dial gauge at right angles.

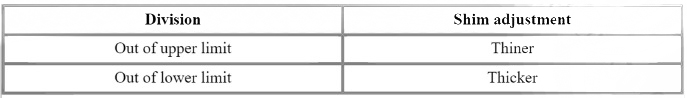

- After moving the SST (0K530-P2400) left and right, read the dial gauge and measure the backlash

WARNING

- After reading dial gauge, adjust backlash to be within the

standard value range below.

- If the measured value deviates from the

standard value specification, bearing adjustment shim (A) 011

the differential carrier case side.

- Measure the total preload.

Tightening torque : 114.7 - 262.8 N-rn (11.7 - 26.8 kgf m. 84.6 - 193.8 lb ft)

WARNING

- Maintain constant rotation while measuring (about 60 RPM).

- If the measured value deviates from the

standard value specification, bearing adjustment shim (A) on

the differential carrier case side.

- Loosen the bolt and remove the differential carrier case side cover (A).

Tightening torque : 39.2 - 49.0 N m (4.0 - 5.0 kgf rn, 28.9 - 36.1 lb ft)

- Apply the sealant on the adhesive side between differential carrier case and side cover.

WARNING

- Remove the used sealant before applying the sealant.

- Apply evenly 2 - 3mm along the surface of the case.

- Install the differential case side cover (A).

Tightening torque : 39.2 - 49.0 N m (4.0 - 5.0 kgf rn, 28.9 - 36.1 lb ft)

- Install the oil seal on both sides of the differential carrier case using the SST (09501-C9190, 09231-H1100).

WARNING

When installing oil seal, replace oil seal with a new one.

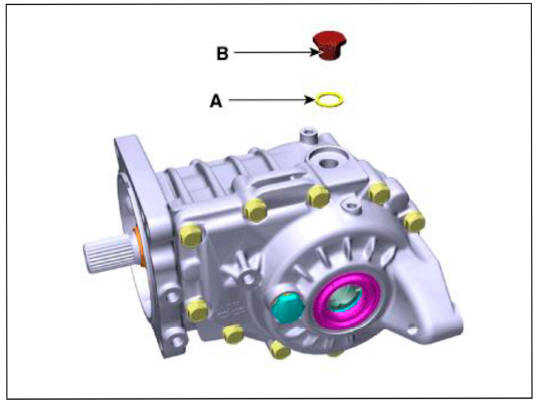

- Install the drain plug packing (A) and drain plug (B) on the differential carrier case.

Tightening torque : 49.0 - 68.6 N-m (5.0 - 7.0 kgfrn, 36.2 - 50.6 lb ft)

WARNING

When installing drain plug packing (A), replace drain plug packing (A) with a new one.

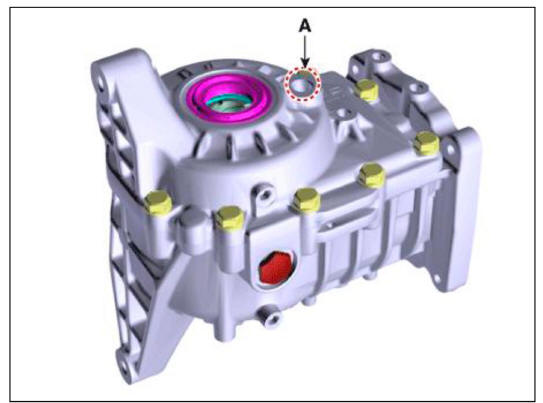

- Add new gear oil through filler plug hole (A).

Hypoid gear oil API GL-5, SAE 75W/85

(SK HCT-5 gear oil 75w/85 or equivalent oil)

0.58+-0.05

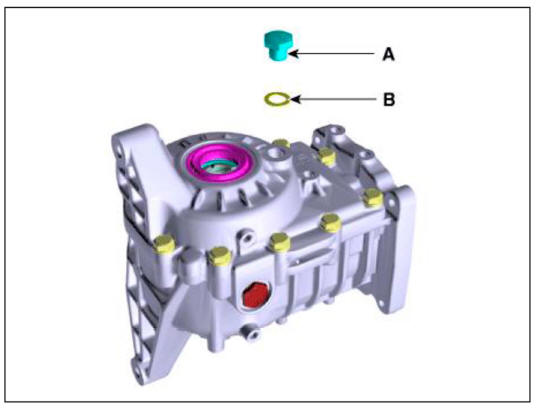

- Install the filler plug (A) and filler gascket (B).

Tightening torque : 39.2 - 58.8 N m (4.0 - 6.0 kgfm, 28.9 - 43.4 lb ft)

WARNING

When installing filler plug gascket (A), replace filler plug gascket (A) with a new one.

READ NEXT:

Differential Carrier Assembly- Installation

Differential Carrier Assembly- Installation

Installation

Install the differential carrier bracket (A).

Install the jack and intall the differential carrier assembly (A).

Tightening torque :

68.6 - 88.3 N m (7.0 - 9.0 kgf m , 50.6 - 65.1 lb ft)

Install the coupling ass

General Information

General Information

Troubleshooting

Wheel and tire diagnosis

Rapid wear at the center

Center-tread down to fabric due to

excessive over inflated tires

Lack of rotation

Excessive toe on drive wheels

Heavy acceleration on drive

Rapid wear at both sh

SEE MORE:

Transmission Control Module (TCM) Inspection Procedure - Installation

Transmission Control Module (TCM) Inspection Procedure - Installation

Installation

To install, reverse the removal procedure.

WARNING

The existing O-rings (A) must be replaced with a new one. (Do not

reuse it.)

Perform the clutch compensation value setting procedure using the

diagnostic tool after rep

Brake Pedal

Brake Pedal

Components

Brake member assembly

Stop lamp switch

Brake pedal arm assembly

Brake pedal pad

Schematic Diagram

System circuit diagram

Terminal Function

Adjustment

Turn ignition switch OFF and disconnect the negat

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual