Hyundai Tucson: The DCT system- Installation

Installation

- To install, reverse the removal procedures.

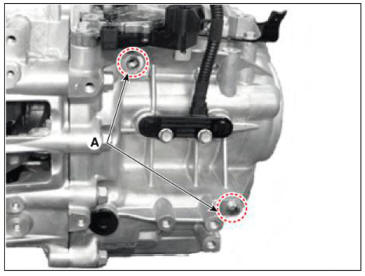

- Check the assembled state of the dowel pins (A) before installing the clutch acmator assembly.

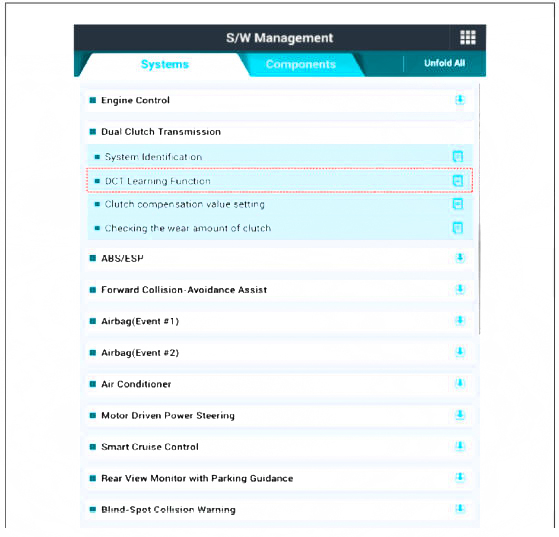

- Perform the clutch touch point learning procedure using the diagnostic tool.

WARNING

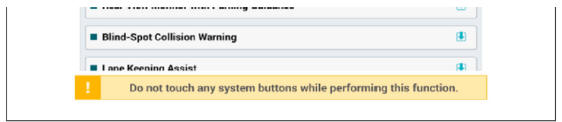

- Before performing the DCT learning procedure using diagnostic tool, perform the learning process after leaving for 5 minutes in the idle state. Because it may be a problem to operation of wear compensation device when entering the DCT learning function at battery low voltage condition.

- When performing the DCT learning function. Perform the DCT learning function twice to ensure accuracy and reliability of the clutch touch point.

- When the ignition is turned off after completing the 2 steps of the DCT learning procedure, the operation of wear compensation device will be performed. It takes up to 6 minutes for the operation of the wear compensation device to be completed, during which time it should not be started engine.

- The engine must be started after at least 6 minutes to ensure that the wear compensation device is fully operated, (keep the engine off for at least 6 minutes)

- If the engine is started while the wear compensation device is operating, sufficient operation of the wear compensation device is not possible, so the excessive operation of the wear compensation device may occur in the next engine starting cycle

WARNING

- Even if you removed and reinstalled the clutch acmator. be sure to perform the touch point learning.

- If you have replaced the dual clutch assembly or clutch acmator, be sure to perform the touch point learning.

READ NEXT:

The DCT system-Adjustment

The DCT system-Adjustment

Adjustment

WARNING

If you replaced the dual clutch assembly or clutch actuator, be

sure to perform wear compensation by referring to the

following table.

If the rod length is less than 52 mm (2.0472 in.), replace all

of the dual cl

Gear acmator assembly

Gear acmator assembly

Components

Gear acmator assembly

Specification

Connector and Terminal Function

Circuit Diagram

Inspection

The DCT system can be more quickly diagnosed for troubles by using the

vehicle diagnostic system (diagnosti

Gear acmator assembly- Description

Gear acmator assembly- Description

Components location : DCT (Dual Clutch Transmission)

Function

The input shaft speed sensor is important in that it detects the input shaft

RPM and sends this

information to the Transmission Control Module (TCM).

It provides important

SEE MORE:

Curtain Air Bag (CAB)

Curtain Air Bag (CAB)

Components Location

Curtain Air Bag (CAB)

Removal

Disconnect the batteiy negative terminal.

WARNING

After disconnecting the cables, wait at least 3 minutes.

Remove the roof trim.

(Refer to Body - "Roof Trim Assembly"

Components and Components Location

Components and Components Location

Components Location

Engine Control Module (ECM)

Mass Air Flow Sensor (MAFS)

Manifold Absolute Pressure Sensor (MAPS)

Intake Air Temperature Sensor (IATS)

Boost Pressure Sensor (BPS)

Engine Coolant Temperature Sensor (E

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual