Hyundai Tucson: Gear acmator assembly

Components

- Gear acmator assembly

Specification

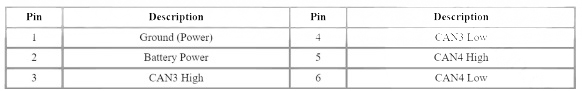

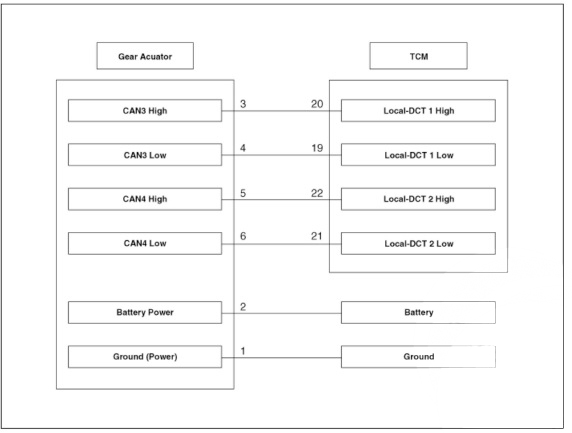

Connector and Terminal Function

Circuit Diagram

Inspection

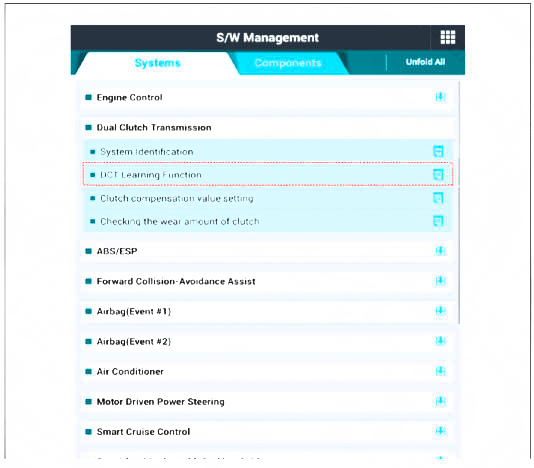

- The DCT system can be more quickly diagnosed for troubles by using the vehicle diagnostic system (diagnostic tool). (Refer to DTC guide) diagnostic tool provides the following information.

1) Self diagnosis : Inspects and displays diagnostic trouble code (DTC)

2)CAN signals: Checks the system input/output value status

3)Forced operation : Checks the system operating stams

4)Additional function : Controls system options, zero point adjustment and other functions

Removal

- Turn ignition switch OFF and disconnect the negative (-) battery cable.

- Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air cleaner")

- Remove the ECM.

(Refer to Engine Control / Fuel System - "Engine Control Module (ECM)")

- Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

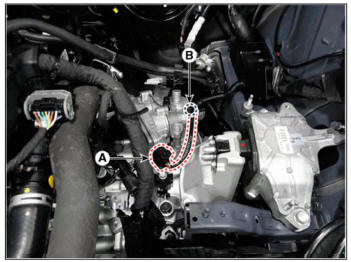

- Disconnect the gear actuator connector (A).

- Loosen the gear actuator wiring bracket mounting bolts (B).

Tightening torque : 9.8- 11.8 N.m (1.0- 1.2 kgf.m. 7.2 - 8.7 lb-ft)

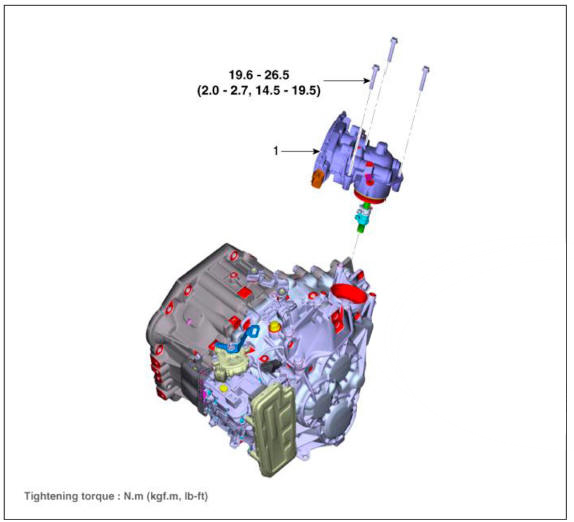

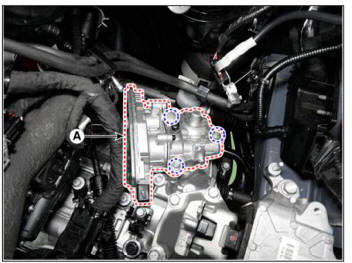

- Loosen the bolts and then removing the gear actuator (A).

Tightening torque : 19.6 - 26.5 N.m (2.0 - 2.7 kgf.m, 14.5 - 19.5 lb-ft)

Installation

- To install, reverse the removal procedure.

WARNING

- Check the details below before installing the gear acmator assembly.

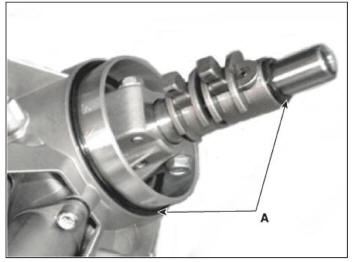

1)Check that the gear acmator is placed in the "neutral" state.

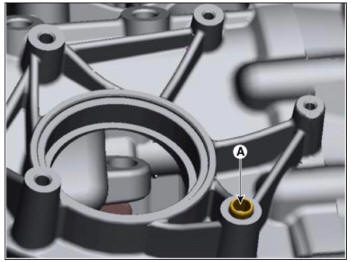

2)Check the assembled state of the O-rings (A).

3)Apply gear oil to the surface of O- rings.

4)Check the assembled state of the dowel pins (A).

- Perform the clutch touch point learning procedure using the diagnostic tool after replacing the clutch acmator assembly.

READ NEXT:

Gear acmator assembly- Description

Gear acmator assembly- Description

Components location : DCT (Dual Clutch Transmission)

Function

The input shaft speed sensor is important in that it detects the input shaft

RPM and sends this

information to the Transmission Control Module (TCM).

It provides important

Inhibitor switch/ Manual control lever

Inhibitor switch/ Manual control lever

Components

Inhibitor switch

Manual control lever

Fault Diagnosis

Fault Diagnosis for Symptom

Specifications

Signal Code Table

Inspection

WARNING

Thoroughly check connectors for looseness, poor connection, bending,

cor

Inhibitor switch/ Manual control lever- Removal

Inhibitor switch/ Manual control lever- Removal

Turn ignition switch OFF and disconnect the batteiy negative (-)

terminal.

Make sure vehicle does not roll before setting shift lever to "N"

position.

Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical

SEE MORE:

Wireless power charging

Wireless power charging

Components

Wireless power charging unit

Wireless power charging lamp

Troubleshooting

Wireless Power Charger System Troubleshooting

R-l. Check the wireless power charger system operation

If the placement of a mobile phone is not

Description of ESP

Description of ESP

Electronic Stability Control (ESC) recognizes critical driving conditions,

such as panic reactions in dangerous situations, and

stabilizes the vehicle by individual wheel braking and engine control input.

ESC adds an additional function known a

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual