Hyundai Tucson: Filling check

WARNING

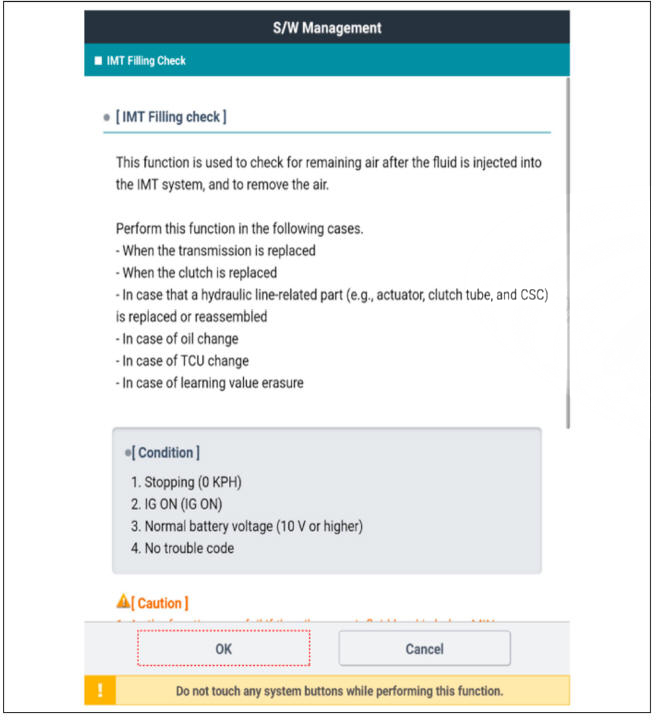

- The procedure below shows about residual air check and removing it if necessary by using the diagnostic tool after refilling the IMT system with clutch fluid.

- The "IMT filling check" procedure should be performed after reinstalling the hydraulic line related parts such as Concentric Slave Cylinder, Clutch Tube, IMT System Actuator.

- The "IMT filling check" procedure should be performed after removing and reinstalling the transmission from the engine such as clutch and fly wheel replacement

- Fill the reservoir with clutch fluid to the "MAX" level.

Specified fluid : DOT4-LV (Recommended). DOT3 or DOT4 (Usable)

- Perform the "IMT filling check" using diagnostic tool.

WARNING

- To prevent accidents caused by vehicle movement, perform the "IMT filling check" after the engaging the parking brake.

- If fluid is below MIN level while performing air bleeding, replenish fluid with MAX level.

WARNING

- Check the below sensor data by using the diagnostic tool.

- Engine power on

- Current gear "N"

- Accel. Position Sensor 0 %

- Clutch pedal sensor 0 %

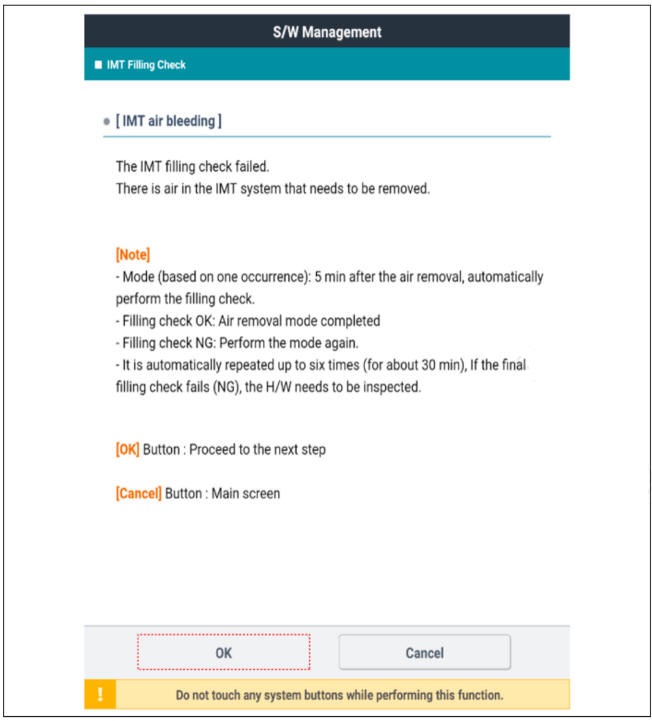

- If the IMT filling check failed, perfome the air bleeding procedures.

Ruuuiug-iu of actuator

WARNING

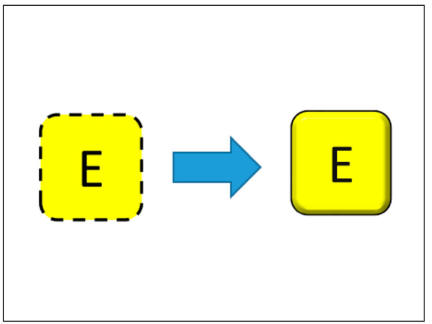

- Filling check status can be checked through the cluster lamp.

- Prior to filling check. E lamp blinks. After filling check is

completed, the "E" lamp lights up.

- IMT system actuator forced operation should be performed, if replaced IMT system actuator with a new one.

WARNING

After complete the filling check, selecting combo box pops up for choosing.

- When the engine power is turned on. the touch point learning would be performed automatically

WARNING

If driver interrupt the learning by manipulating any pedals, the learning would be stopped. When the condition of the learning is satisfied, the learning would be performed anytime.

Clutch touch-point learning

WARNING

- Clutch touch-point learning status can be checked through the cluster lamp.

- Prior to learning. "E" lamp turns on. After learning, the current gear position (N) replaces the "E" lamp and blinks.

- Check the below sensor data by using the diagnostic tool.

(1) Current gear "N"

(2) Accel. Position Sensor 0 %

(3) Clutch pedal sensor 0 %

WARNING

- Engine power on

- Current gear "N"

- Accel. Position Sensor 0 %

- Clutch pedal sensor 0 %

- When the engine power is turned on. the touch point learning would be performed automatically.

WARNING

If driver interrupt the learning by manipulating any pedals, the learning would be stopped. When the condition of the learning is satisfied, the learning would be performed anytime.

- Check a sensor data value.

"Touch-point learning finished"

WARNING

- If the shift lever is located "N" but the sensor data of

"Current gear" isn't displayed "N", inspection of the lever and

control cable is required.

(Refer to IMT(intelligent Manual Transaxle) Control System - "Control Cable")

Torque - Stroke learning

WARNING

- Clutch torque - Stroke learning status can be checked through the cluster lamp.

- Prior to learning, the current gear position (N) lamp blinks. After learning, the current gear position (4) lamp lights up.

- Drive the vehicle with below condition.

(1) Launch the vehicle and shift gear l→2→3 rapidly under 30 kph.

(2) Drive the vehicle with below APS 30% in 3rd gear for about 20 seconds up to 70 kph. (APS have to be keep the least of fluctuating)

(3) Shift the gear to 3rd → 4th above 70 kph vehicle speed.

- Check a sensor data value.

"Torque - stroke learning finished"

READ NEXT:

IMT Control Module (TCM)

IMT Control Module (TCM)

Description

Function

The transaxle Control Module (TCM) is like the brain for the Intelligent

Manual transaxle (IMT). It

receives information from various sensors for a wide range of transaxle controls

to provide an optimal

driving environmen

IMT System Actuator

IMT System Actuator

Components and Components Location

IMT system actuator

Connector and Terminal Information

Circuit Diagram

IMT System Actuator- Replacement

IMT System Actuator- Replacement

iMT system actuator fluid - when fluid suction tool is available

Remove the air cleaner assembly and the air duct.

(Refer to Engine Mechanical System - "Air Cleaner")

Remove the reservoir cap (A) and drain the imt system actuator

SEE MORE:

Surround View Monitor (SVM)

Surround View Monitor (SVM)

Surround View Monitor can help assist in

parking using the cameras installed on

the vehicle and displays images around

the vehicle through the infotainment

system screen.

Parking Assist View function helps

the driver to see the surround

Driver side temperature control actuator / Passenger side temperature

control actuator

Driver side temperature control actuator / Passenger side temperature

control actuator

Component Location

Driver side temperature control actuator

Passenger side temperature control actuator

Inspection

Turn the ignition switch OFF.

Disconnect the temperature control actuator connector.

Verify that the temperature c

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual