Hyundai Tucson: Brake Booster Operating

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / Brake System / Braking System - operation and description / Brake Booster Operating

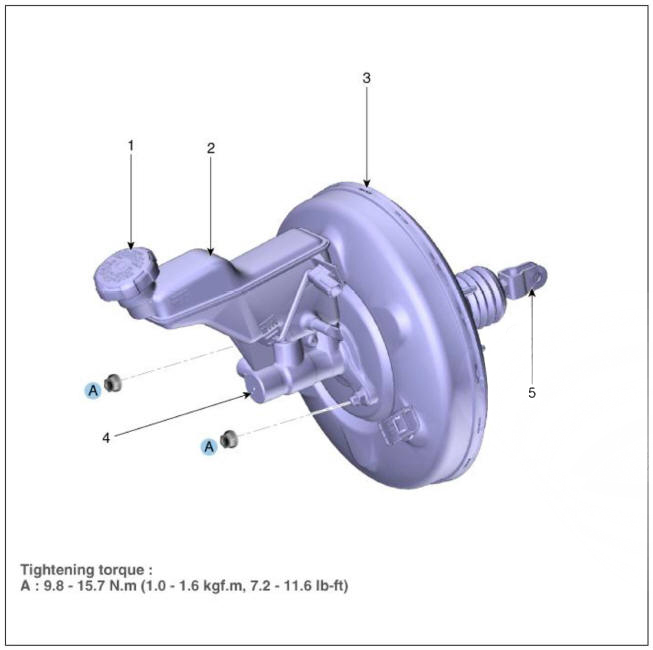

Components

- Reservoir cap

- Reservoir

- Brake booster

- Master cylinder

- Push rod

Test

- Run the engine for one or two minutes, and then stop it. If the pedal depresses fully the first time but gradually becomes higher when depressed succeeding times, the booster is operating properly, if the pedal height remains unchanged, the booster is inoperative.

- With the engine stopped, step on the brake pedal several times.

Then step on the brake pedal and start the engine. If the pedal moves downward slightly, the booster is in good condition. If there is no change, the booster is inoperative.

- With the engine running, step on the brake pedal and then stop the engine.Hold the pedal depressed for 30 seconds. If the pedal height does not change, the booster is in good condition, if the pedal rises, the booster is inoperative.

If the above three tests are okay, the booster performance can be determined as good.

Even if one of the above three tests is not okay, check the check valve, vacuum hose and booster for malfunction.

Removal

- Turn ignition switch OFF and disconnect the negative (-) battery cable.

- Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

- Remove the air duct and air cleaner assembly.

(Refer to Intake and Exhaust System - "Air Cleaner")

- Remove the master cylinder.

(Refer to Brake System - "Master Cylinder")

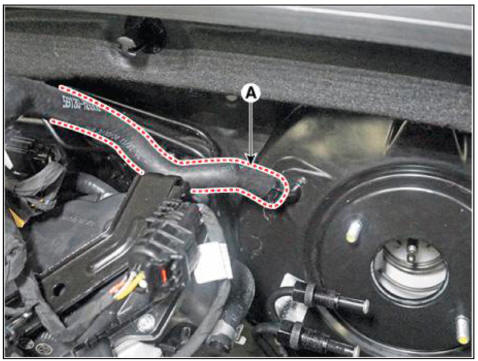

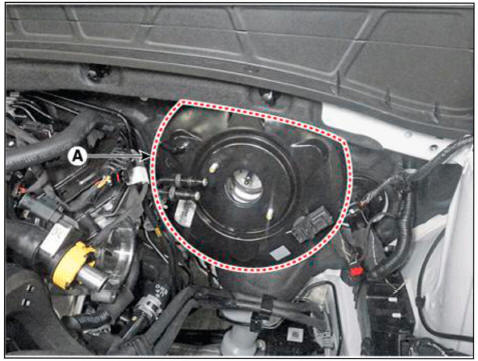

- Remove the fixing clip and the vacuum hose (A) from the brake booster.

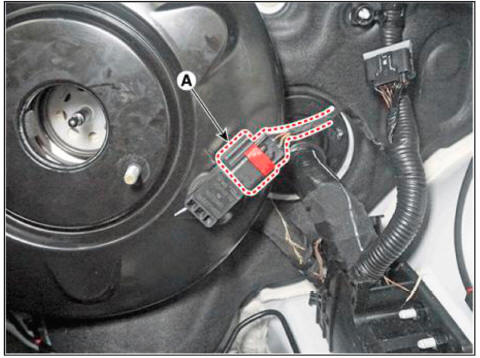

- Disconnect the brake booster vacuum pressure sensor connector (A).

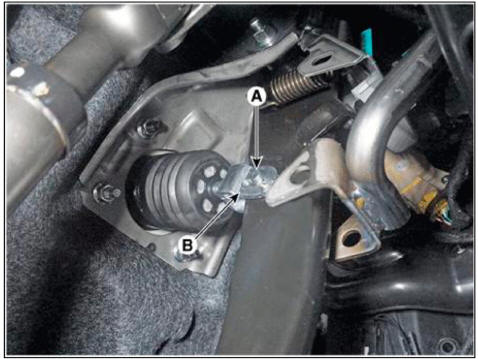

- Remove the snap pin (B) and the clevis pin (A).

- Remove the brake booster (B) after loosening the mounting nuts (A).

Tightening torque : 16.7 - 25.5 N.m (1.7 - 2.6 kgf.m, 12.3 - 18.8 lb-ft)

Inspection

- Inspect the vacuum hose.

- Check the boot for damage.

Installation

- Installation is the reverse of removal.

WARNING

- Before installing the pin. apply the grease to the joint pin.

- Use a new snap pin whenever installing.

- After installation, bleed the brake system.

(Refer to Brake System - "Brake Bleeding Procedures")

- Check the brake oil leakage and pedal operating condition.

READ NEXT:

Brake Booster - Removal

Brake Booster - Removal

Components

Reservoir cap

Reservoir

Brake booster

Master cylinder

Push rod

Removal

Turm ignition switch OFF and disconnect the negative (-) battery cable.

Remove the battery.

(Refer to Engine Electrical System - "Batter

Brake Tube Engine Room

Brake Tube Engine Room

Components

Removal

WARNING

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and

canister) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Su

Brake Tube- Replacement

Brake Tube- Replacement

Replacement

WARNING

Be careful not to damage the parts located under the vehicle (floor

under cover, fuel filter, fuel

tank and canister) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Support Points&q

SEE MORE:

Motor Driven Power Steering- Replacement

Motor Driven Power Steering- Replacement

Replacement

Turn the steering wheel so that the front wheels are placed in the

straight ahead position.

Turn the ignition switch OFF and disconnect the battery negative (-)

cable.

Remove the driver airbag (DAB).

(Refer to Restraint -

Timing System -

Removal

Timing System -

Removal

Disconnect the battery negative terminal.

Turn the crankshaft damper pulley clockwise, and align its groove with

the timing mark of the timing chain

cover.

Remove the timing chain cover.

(Refer to Timing System - "Timing C

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual