Hyundai Tucson: 48V Battery System - Repair procedures (Removal)

- Turn ignition switch OFF and disconnect the battery (-) terminal.

- Remove the 48V battery assembly.

(Refer to 48V Battery System - "Repair procedures")

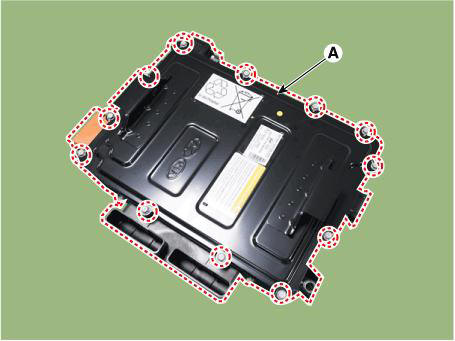

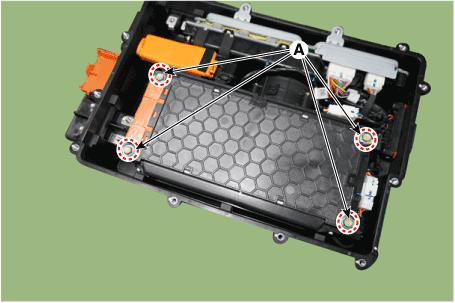

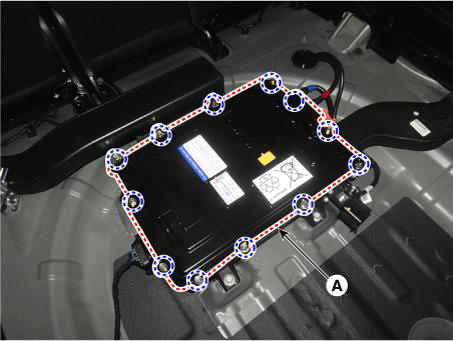

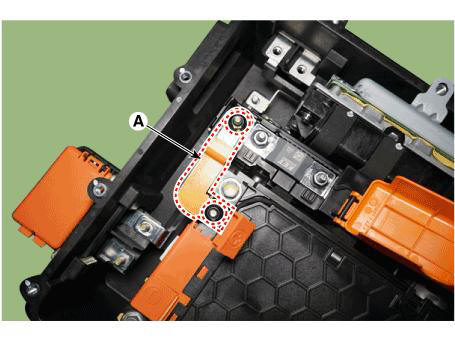

- Remove the battery cover (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

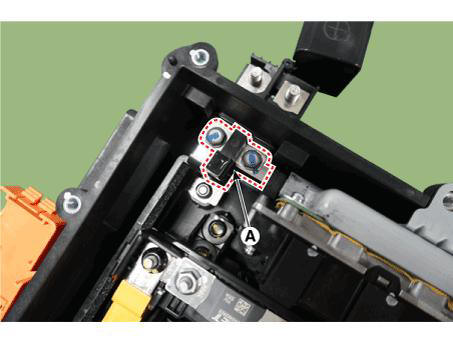

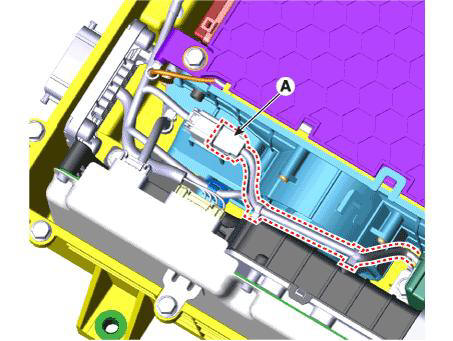

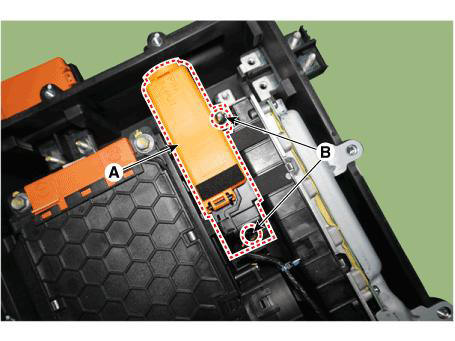

- Remove the terminal capacitor (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

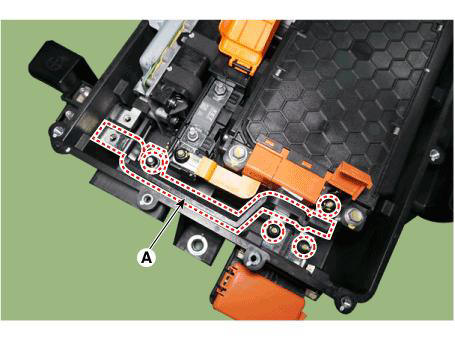

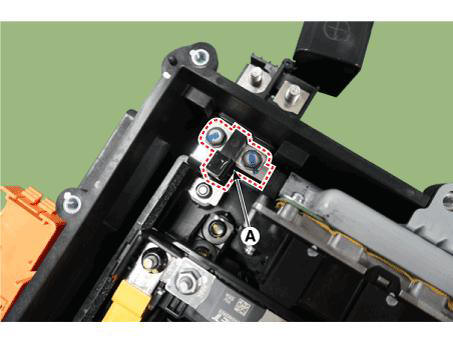

- Remove the mounting nuts and remove the battery module (-) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

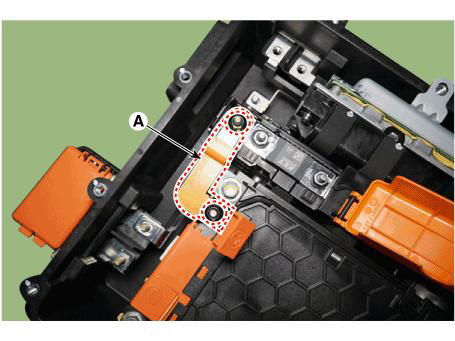

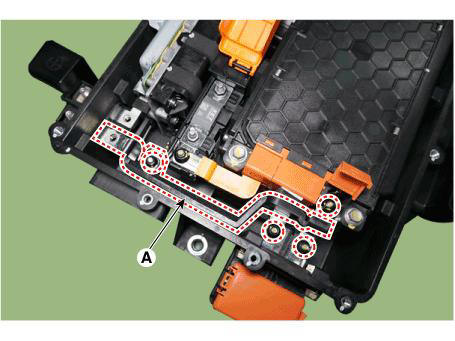

- Remove the mounting nuts and remove the battery module (+) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the BMS wiring harness terminal after loosening the mounting bolts (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the 48V battery case assembly after loosening the mounting bolts (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

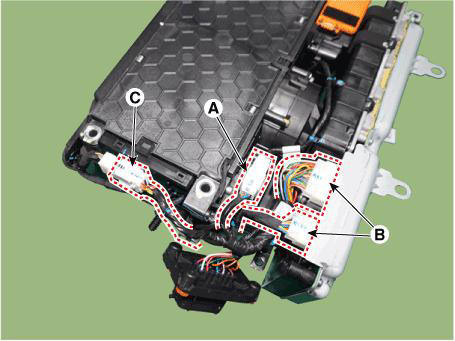

- Disconnect the PRA extension connector (A) and the BMS & LDC connectors (B).

- Disconnect the battery temperature sensor extension connector (C).

- Disconnect the cooling blower fan connector (A).

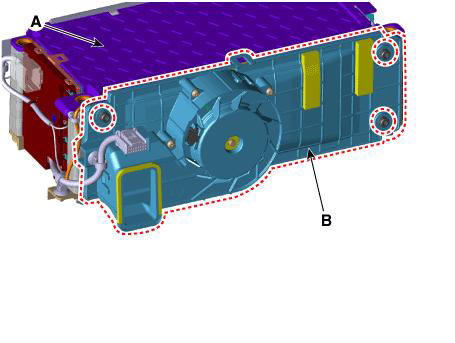

- Remove the battery cooling blower unit (B) from the battery module (A).

Tightening torque : 5.9 - 9.8 N.m (0.6 - 1.0 kgf.m, 4.3 - 7.2 lb-ft)

- Remove the battety module lnlet duct (A) after loosening mountin bolts.

Tightening torque : 3.4 - 6.4 N.m (0.35 - 0.65 kgf.m, 2.5 - 4.7 lb-ft)

Installation

- Install in the reverse order of removal.

Description

The Power Relay Assembly (PRA) consists of the positive main relay. It is located inside the battery pack assembly and controls the high voltage power circuit between the high voltage battery and inverter by the control signal of BMS ECU.

Removal

- Turn ignition switch OFF and disconnect the battery (-) terminal.

- Remove the battery cover (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Disconnect the PRA extension connector (A).

- Remove the terminal capacitor (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the mounting nuts and remove the battery module (-) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the mounting nuts and remove the battery module (+) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the PRA assembly (A) after loosening the mounting bolts (B).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

Installation

- Install in the reverse order of removal.

READ NEXT:

BMS ECU Terminal and Input/Output Signal

BMS ECU Terminal and Input/Output Signal

Terminal Function

Connector B10-A

Connector B01-B

Removal

Turn ignition switch OFF and disconnect the battery (-) terminal.

Remove the 48V battery assembly.

(Refer to 48V Battery System - "Repair procedures")

Power Relay Assembly (PRA) - Removal

Power Relay Assembly (PRA) - Removal

Removal

Remove the PRA assembly.

(Refer to 48V Battery System - "Power Relay Assembly (PRA)")

Remove the PRA cover.

Remove the mounting bolts and remove the power relay busbar (A).

Disconnect the main relay connector

Battery Pack Assembly Inlet Duct/ Battery Pack

Assembly Outlet Duct

Battery Pack Assembly Inlet Duct/ Battery Pack

Assembly Outlet Duct

Removal and

Installation

Battery Pack Assembly Inlet Duct

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Remove the luggage board (A).

Separate the inlet cooling duct (A) in the direction of the arrow.

Tigh

SEE MORE:

Gear acmator assembly- Description

Gear acmator assembly- Description

Components location : DCT (Dual Clutch Transmission)

Function

The input shaft speed sensor is important in that it detects the input shaft

RPM and sends this

information to the Transmission Control Module (TCM).

It provides important

Engine Mechanical System - Removal

Engine Mechanical System - Removal

Removal

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

Remove the engine room under cover.

(Refer to Engine Mechanic

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual