Hyundai Tucson: Power Relay Assembly (PRA) - Removal

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / Engine Electrical System / 48V Battery System / Power Relay Assembly (PRA) - Removal

Removal

- Remove the PRA assembly.

(Refer to 48V Battery System - "Power Relay Assembly (PRA)")

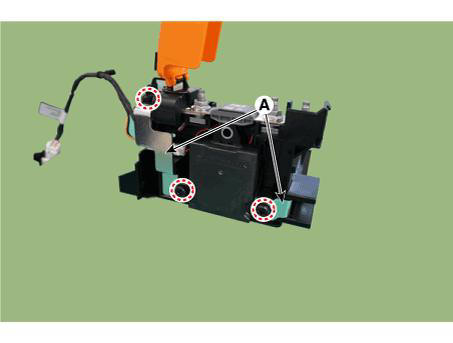

- Remove the PRA cover.

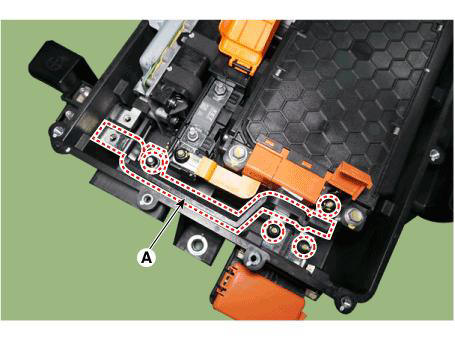

- Remove the mounting bolts and remove the power relay busbar (A).

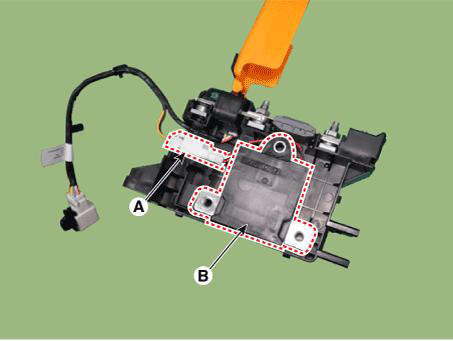

- Disconnect the main relay connector (A).

- Remove the main relay (B).

Installation

- Install in the reverse order of removal.

Removal

- Turn ignition switch OFF and disconnect the battery (-) terminal.

- Remove the 48V battery assembly.

(Refer to 48V Battery System - "Repair procedures")

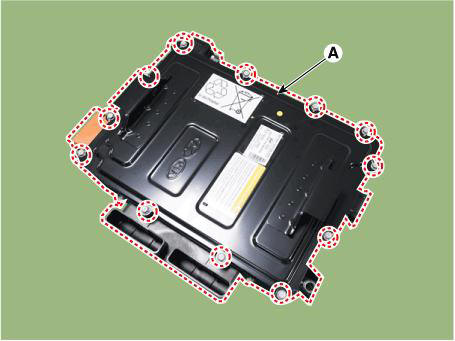

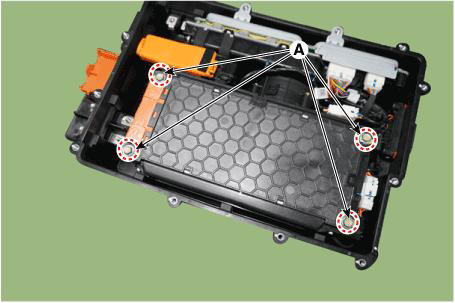

- Remove the battery cover (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

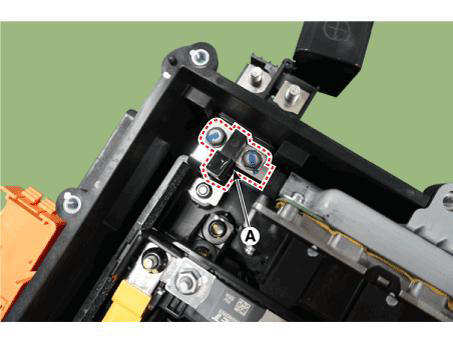

- Remove the terminal capacitor (A) after loosening the mounting bolts.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the mounting uuts and remove the battery module (-) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the mounting nuts and remove the battery module (+) busbar (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the BMS wiring harness terminal after loosening the mounting bolts (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Remove the 48V battery case assembly after loosening the mounting bolts (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

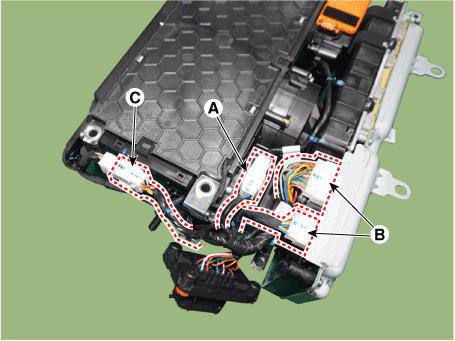

- Disconnect the PRA extension connector (A) and the BMS & LDC connectors (B).

- Disconnect the battery temperature sensor extension connector (C).

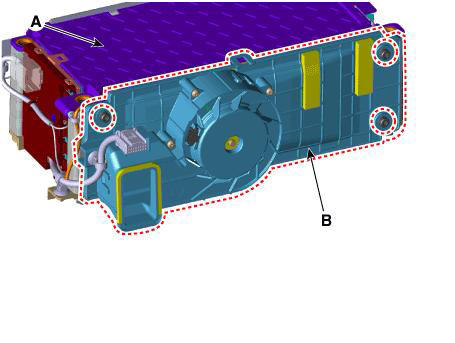

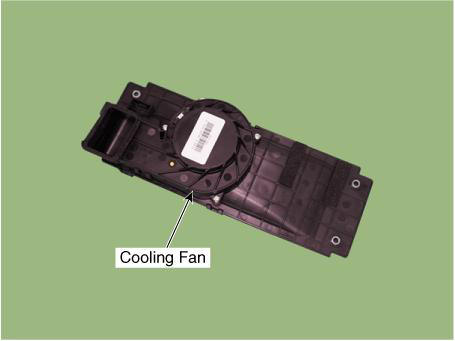

- Disconnect the cooling blower fan connector (A).

- Remove the battery cooling blower unit (B) from the battery module (A).

Tightening torque : 5.9 - 9.8 N.m (0.6 - 1.0 kgf.m, 4.3 - 7.2 lb-ft)

Installation

- Install in the reverse order of removal.

READ NEXT:

Battery Pack Assembly Inlet Duct/ Battery Pack

Assembly Outlet Duct

Battery Pack Assembly Inlet Duct/ Battery Pack

Assembly Outlet Duct

Removal and

Installation

Battery Pack Assembly Inlet Duct

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Remove the luggage board (A).

Separate the inlet cooling duct (A) in the direction of the arrow.

Tigh

Battery Module Inlet Duct

Battery Module Inlet Duct

Turn ignition switch OFF and disconnect the battery (-) terminal.

Remove the 48V battery assembly

(Refer to 48V Battery System - "Repair procedures")

Remove the battery cover (A) after loosening the mounting bolts.

Tightening

Battery Module Inlet B Duct

Battery Module Inlet B Duct

Remove the 48V battery assembly.

(Refer to 48V Battery System - "Repair procedures")

Remove the battery pack assembly inlet duct B (A) after loosening the

mounting bolts.

Install in the reverse order of removal.

Sp

SEE MORE:

Timing System - Replacement

Timing System - Replacement

Components

Variable force solenoid valves

Timing chain cover

Cam to cam guide

Timing chain

Timing chain tensioner arm

Timing chain tensioner arm

Timing chain tensioner

Crankshaft sprocket

Oil pump chain

Oil pump chain tensio

Automatic heating and air conditioning

Automatic heating and air conditioning

Driver's temperature control button/

knob

Passenger's temperature control

button/knob

AUTO (automatic control) button

Air intake control button

OFF button

Front windshield defroster button

A/C (air conditioning) button

Fan sp

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual