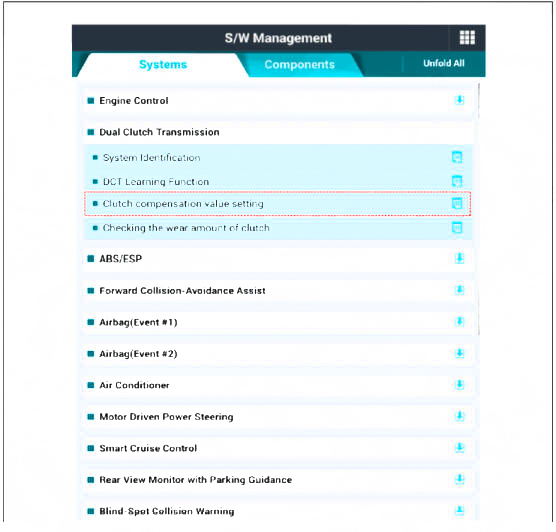

Hyundai Tucson: Transmission Control Module (TCM) Inspection Procedure

Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual / DCT (Dual Clutch Transmission) System / DCT (Dual Clutch Transmission) System (SBC) / Transmission Control Module (TCM) Inspection Procedure

Inspection

- Inspecting TCM ground circuit: Measure the resistance between the TCM

and chassis ground.

(Check the terminal connected to the chassis ground while using the back of the harness connector as the base point for TCM.)

Normal reading (resistance): Below 1

- Inspecting the TCM connector: Disconnect the TCM connector and visually inspect to see whether there is a bend on the ground terminal of the harness connector. Also visually check the connection pressure.

- If no problem is found during inspection in step 1 and step 2, then the problem is with the TCM itself. In this case, replace the TCM and inspect the vehicle again.

- Re-inspecting TCM: Install the TCM that was determined to have malfunctioned from step 3 in another vehicle. Reset the error code and then check the operation in that vehicle. If the vehicle operates without any problems, then inspect the first vehicle with the initial problem again.

Removal

- Prior to replacing the TCM, check the TCM clutch compensation value with the diagnostic tool tool.

- Turn ignition switch OFF and disconnect the battery negative (-) terminal.

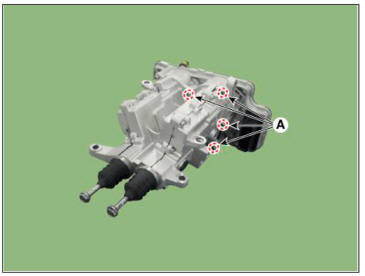

- Remove the clutch actuator assembly.

(Refer to Dual Clutch Transmission Control System - "Clutch Actuator & TCM Assembly")

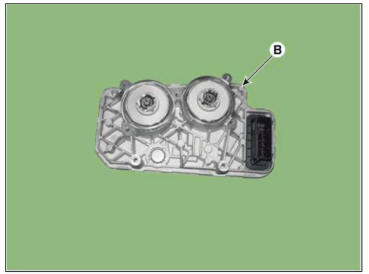

- Loosen the bolts (A) and then removing the TCM (B).

Tighteuning torque: 7.8 - 9.8 N.m (0.8 - 1.0 kgf.m. 5.8 - 7.2 lb-ft)

READ NEXT:

Transmission Control Module (TCM) Inspection Procedure - Installation

Transmission Control Module (TCM) Inspection Procedure - Installation

Installation

To install, reverse the removal procedure.

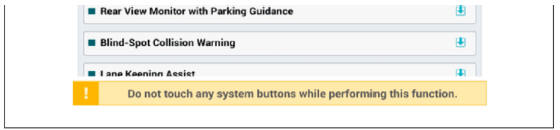

WARNING

The existing O-rings (A) must be replaced with a new one. (Do not

reuse it.)

Perform the clutch compensation value setting procedure using the

diagnostic tool after rep

The DCT system

The DCT system

Components

Fork cover

Clutch actuator & TCM assembly

Clutch actuator assembly

O-ring

DCT control module (TCM)

Specification

Inspection

The DCT system can be more quickly diagnosed for troubles by using the

vehicle diagn

The DCT system- Installation

The DCT system- Installation

Installation

To install, reverse the removal procedures.

Check the assembled state of the dowel pins (A) before installing the

clutch acmator assembly.

Perform the clutch touch point learning procedure using the diagnostic

tool.

SEE MORE:

Clutch Regulator

Clutch Regulator

Components and Components Location

Clutch pedal arm

Clutch pedal assembly

Reservoir hose

Regulator

Cluch tube

Clutch hose

Removal

Remove the air cleaner assembly and air duct.

(Refer to In case by Gasoline 1.6 T-GDI System

Free Running Inspection

Free Running Inspection

Place the starter motor in a vise equipped with soft jaws and connect a

fully-charged 12-volt battery to

starter motor as follows.

Connect a test ammeter (150-ampere scale) and carbon pile rheostats

shown is the illustration.

Connect a

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual