Hyundai Tucson: Suction & Liquid Pipe Assembly

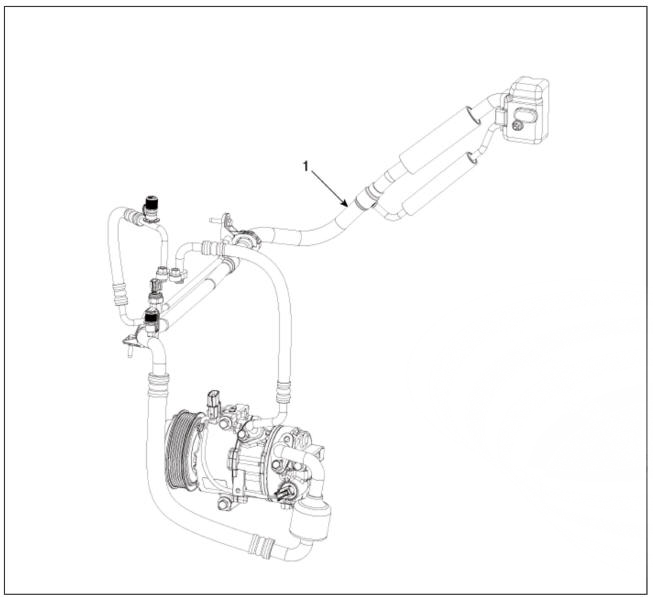

Components

- Suction & Liquid Pipe Assembly

Replacement

- If a compressor is available, the air conditioner is operated for a few minutes in the engine idle state and then the engine is stopped.

- Disconnect the negative (-) batteiy terminal.

- Recover the refrigerant with a recovery/charging station.

(Refer to Air conditioning System - "Repair procedures")

- Remove the engine cover.

(Refer to Engine Mechanical System - "Engine Cover")

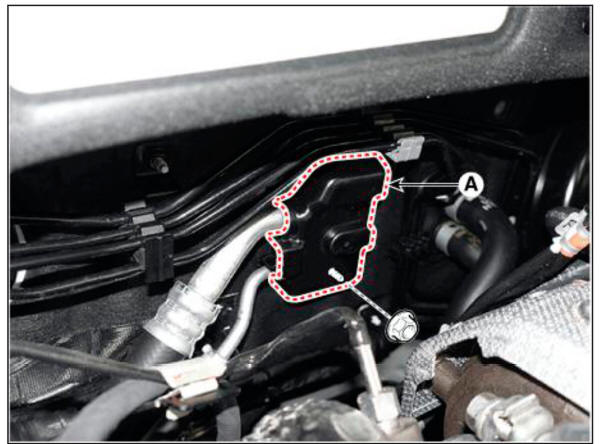

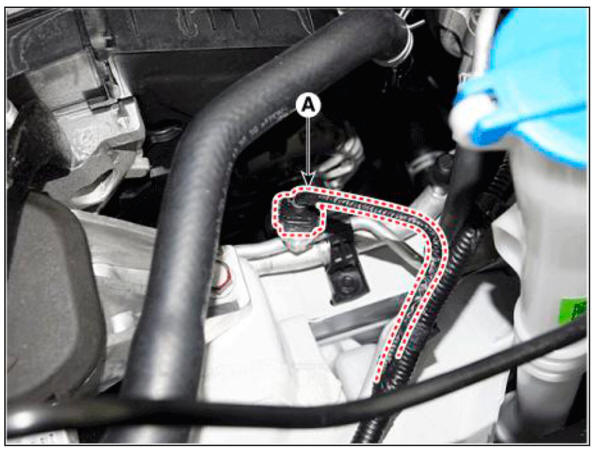

- Loosen the mounting nut and separate the expansion valve cover (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

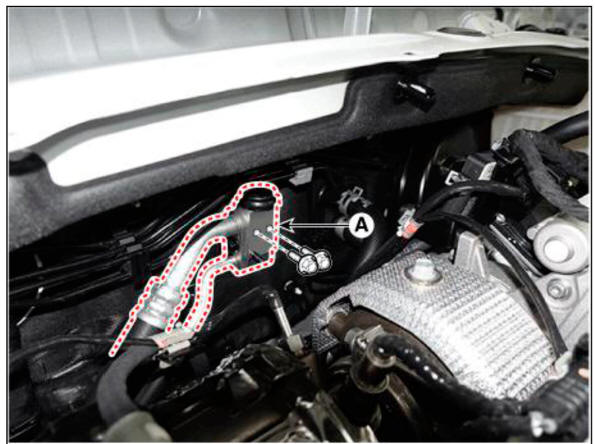

- Loosen the mounting bolts and separate the expansion valve (A) fron evaporator core.

Tightening torque : 21.6 - 32.4 N.m (2.2 - 3.3 kgf.m, 15.9 - 23.9 lb-ft)

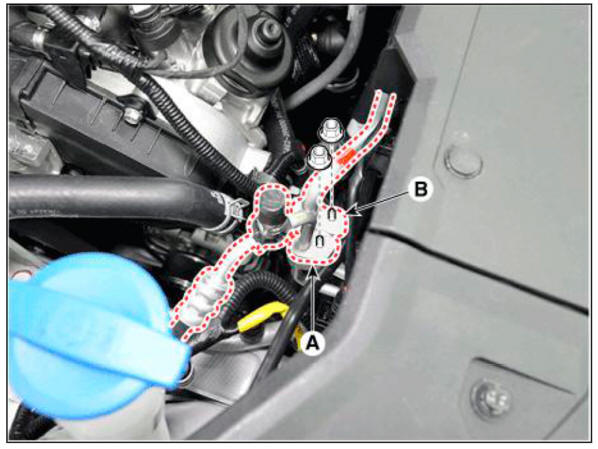

- Loosen the mounting nuts and separate the suction line (A), discharge line (B).

Tightening torque : 19.6 - 23.5 N.m (2.0 - 2.4 kgf.m. 14.5 - 17.4 lb-ft)

- Disconnect the APT sensor connector (A).

- Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

- Remove the engine mounting braket.

(Refer to Engine Mechanical System - "Engine Mounting")

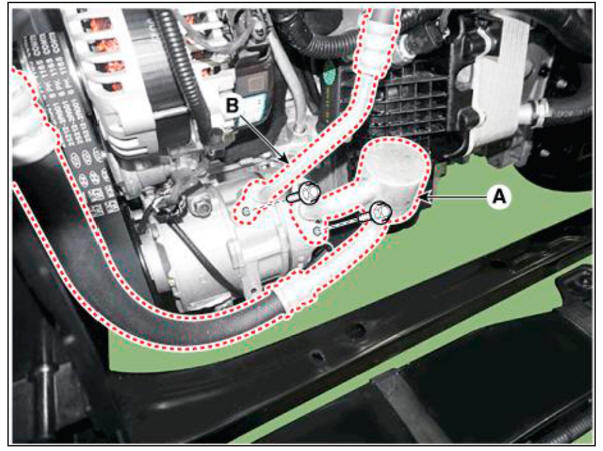

- Separate the compressor suction line (A) and discharge line (B) connection nuts and disconnect the line.

Tightening torque : 21.6 - 32.4 N.m (2.2 - 3.3 kgf.m, 15.9 - 23.9 lb-ft)

WARNING

Be care fill not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.

(Refer to General Information - "Lift and Support Points")

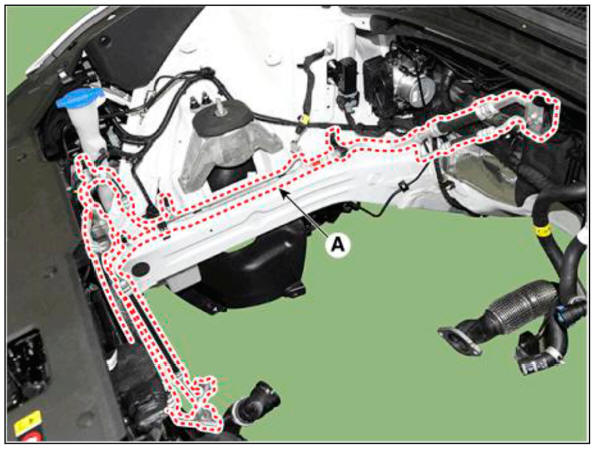

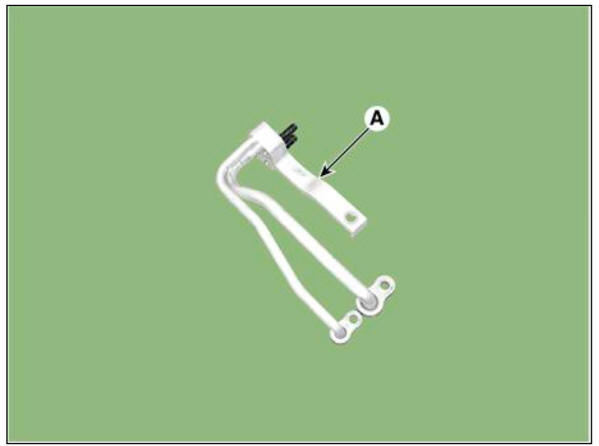

- Loosen the mounting bolt and remove the Front suction & Liquid pipe assembly (A).

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Install in the reverse order of removal.

WARNING

- Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

- Tighten the bolt or nut joint to the specified torque.

- Using a gas leak detector, check for refrigerant leakage.

- Evacuate air in the refrigeration system and charge system with refrigerant.

Capacity :

R-1234yf: 550 +- 25g (17.7 = 0.88oz)

R-134a : 600 +- 25g (19.29 +- 0.88oz)

Refrigerant Line (Condenser)

- Remove the front bumper assembly.

(Refer to Body (Interior and Exterior) - "Front Bumper Assembly")

- Recover the refrigerant with a recovery/charging station.

(Refer to Air conditioning System - "Repair procedures")

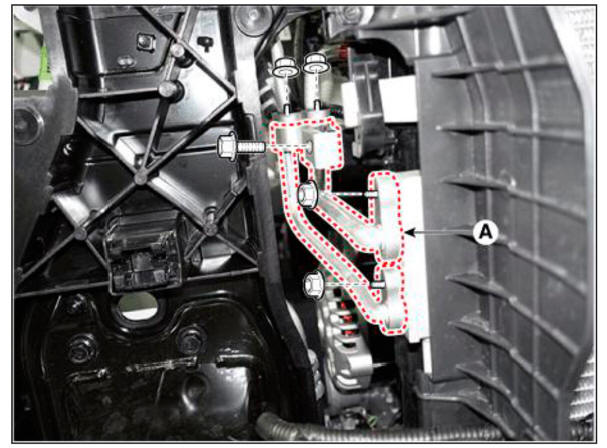

- Loosen the mounting nuts, and then disconnect the liquid line (A) from the condenser.

Tightening torque : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

- Install in the reverse order of removal.

WARNING

- Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

- Tighten the bolt or nut joint to the specified torque.

- Using a ga s leak detector," check for refrige rant leakage.

- Evacuate air in the refrigeration system and charge system with refrigerant.

Capacity : R-1234yf: 550 +- 25g (17.7 +- 0.88oz)

R-134a : 600 +- 25g (19.29 +- 0.88oz)

Description

The compressor is the power unit of the A/C system.

It is located on the side of engine block and driven by a V-belt of the engine.

The compressor changes low pressure and low temperature refrigerant gas into high pressure and high temperature refrigerant

Variable Swash Plate Compressor

The compressor has a swash plate that rotates to reciprocate pistons, which compress refrigerant.

The variable swash plate compressor controls the swash plate angle to change the refrigerant displacement. It achieves precise cooling capability control in accordance with vehicle interior and driving conditions.

The internally controlled variable swash plate compressor changes the swash plate angle by a MCV (Mechanical Control Valve) in accordance with fluctuation of a suction pressure.

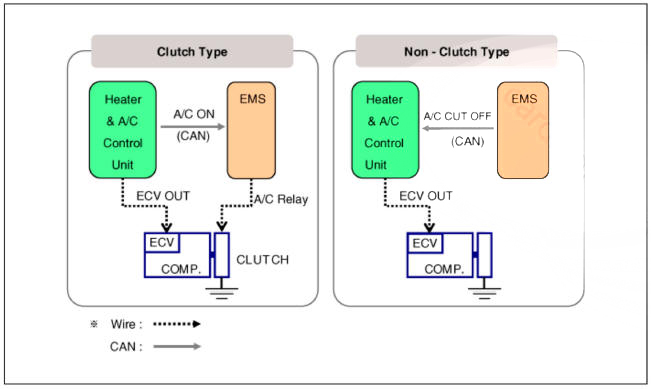

The externally controlled variable swash plate compressor changes the swash plate angle by an ECV (Electric Control Valve) in accordance with an electrical signal from the heater & A/C control unit. This enables stable temperature control and improved driving sensation.

ECV Control Diagram

READ NEXT:

Compressor

Compressor

Components

Compressor

Components

Clutch bolt

Disc & Hub assembly

Snap ring (Rotor)

Pulley

Snap Ring (Stator)

Clutch spacer

Compressor

Electric Control Valve (ECV)

Electric Control Valve (ECV) snap ring

Removal

Compressor - Installation

Compressor - Installation

Make sure that the compressor (A) mounting bolt of the correct length is

screwed in. Tighten the mounting bolts in the

specified tightening order.

Install in the reverse order of removal.

f you install a new compressor, drain

External Control Valve Compressor Inspection (GDS)

External Control Valve Compressor Inspection (GDS)

Compressor type: Fixed type compressor, External control valve, Internal

control valve.

In cases of fixed type and internal control valve, it is possible to inspect

compressor's operation with clutch noise.

When it comes to External con

SEE MORE:

Fuel Pressure Control Valve (FPCV)

Fuel Pressure Control Valve (FPCV)

Description

Installed on the high pressure fuel pump, the Fuel Pressure Regulator Valve

controls the fuel amount

flowing into the injectors in accordance with the ECM signal calculated based on

various engine

conditions.

Specification

EGR cooler- Removal and Installation

EGR cooler- Removal and Installation

Disconnect the battery negative terminal.

Remove the front bumper beam.

(Refer to Body(Interior and Exterior) - "Front Bumper Beam Assembly")

Remove the intercooler mounting bracket (A), and then disconnect the

intake temperat

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual