Hyundai Tucson: Shift Lever

Removal

- Turn ignition switch OFF and then disconnect the battery (-) cable.

- Remove the floor console assembly.

(Re fer to Body (Interior and Exterior) - " Floor Console")

- Remove the floor air duct (A).

- Separate the wiring clips (A. B).

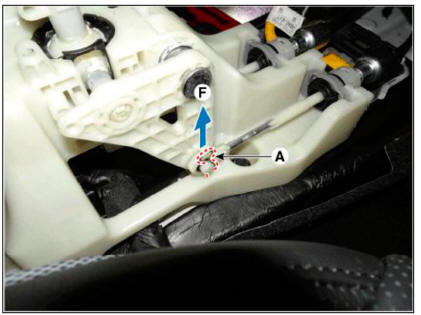

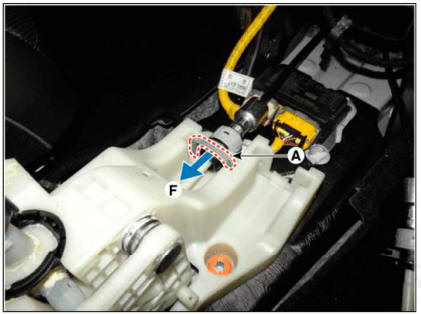

- Remove the snap pin (A) in the arrow "F" direction.

- Separate the select cable end (A) in the arrow "F" direction.

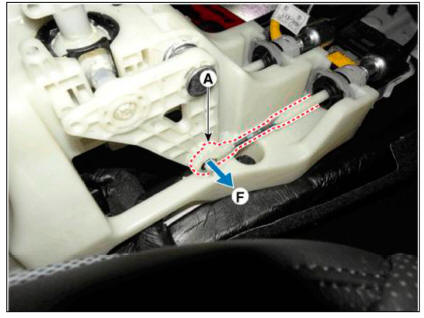

- Separate the select cable socket.

(1) Pull the select cable socket clip (A) in the arrow "F" direction.

(2) Pull the select cable socket (A) in the arrow "F" direction.

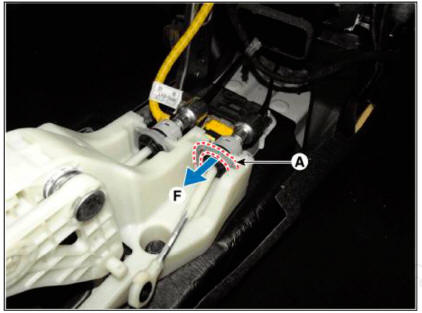

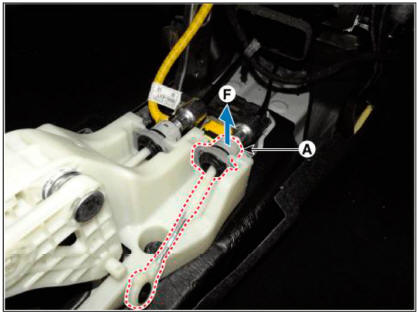

- Separate the shift cable socket.

(1) Pull the shiftt cable socket clip (A) in the arrow "F" direction.

(2) Pull the shiftt cable socket (A) in the arrow "F" direction.

- Loosen the bolts and then separate the shift lever (A).

Tightening torque : 8.8 - 13.7 N.m (0.9 - 1.4 kgf.m, 6.5 - 10.1 lb-ft)

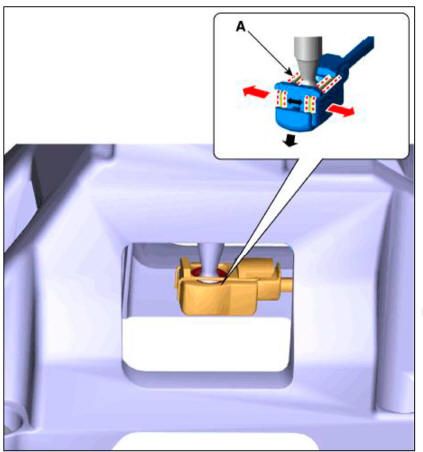

- Remove the clip, in the shape of a "U"(A), from the shift cable end by spreading it towards both sides

- Remove the shift lever (A) from shift cable end.

Installation

- To install, reverse the removal procedures.

WARNING

- New shift lever assembly is mounted in the 4th fixing pin.

- After installation, remove the 4th fixed pin.

- Check operating of lever of transaxle side when operating shift lever after assembly. (1~6,R)

READ NEXT:

Control Cable - Removal

Control Cable - Removal

Turn OFF ignition switch and disconnect the negative (-) batteiy cable.

Remove the air duct and air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

Remove the batteiy and batteiy tray.

(Refer to Engine E

Control Cable- Installation

Control Cable- Installation

Installation

WARNING

Check if the 4th fixing pin (A) is installed.

Install the control cable retainer (B) and then tightening the nuts (A).

Tightening torque:

11.8 - 14.7 N.m (1.2 - 1.5 kgf.m, 8.7 - 10.8 lb-ft)

Install the clip, i

SEE MORE:

Compressor - Installation

Compressor - Installation

Make sure that the compressor (A) mounting bolt of the correct length is

screwed in. Tighten the mounting bolts in the

specified tightening order.

Install in the reverse order of removal.

f you install a new compressor, drain

Driveshaft Assembly- Installation

Driveshaft Assembly- Installation

Installation

To install, reverse the removal procedures.

Check the alignment.

(Refer to Suspension System - "Alingment")

Removal

Remove the front drive shaft.

(Refer to Driveshaft Assembly - "Front Driveshaft")

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual