Hyundai Tucson: Engine Control Module (ECM)

ECM Terminal And Input/Output signal

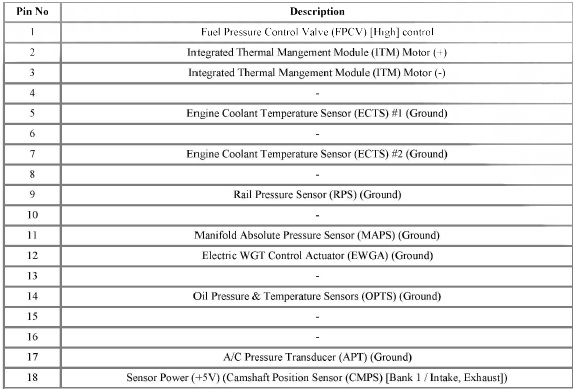

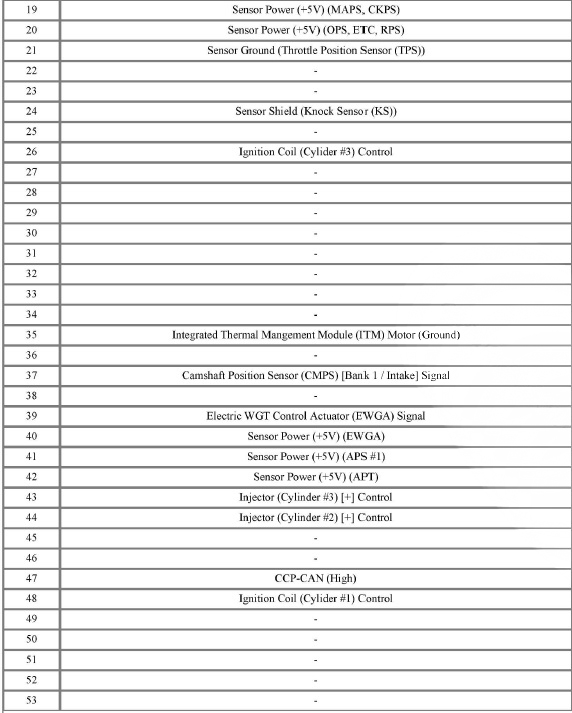

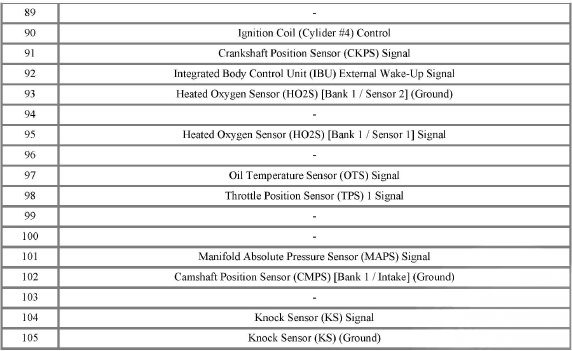

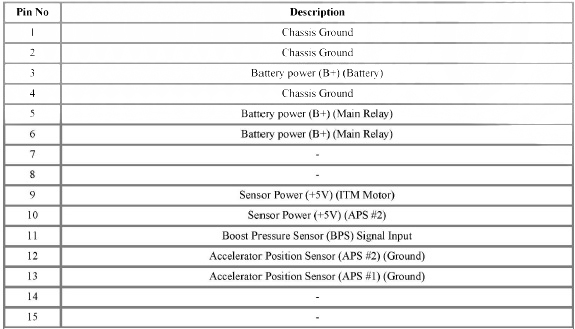

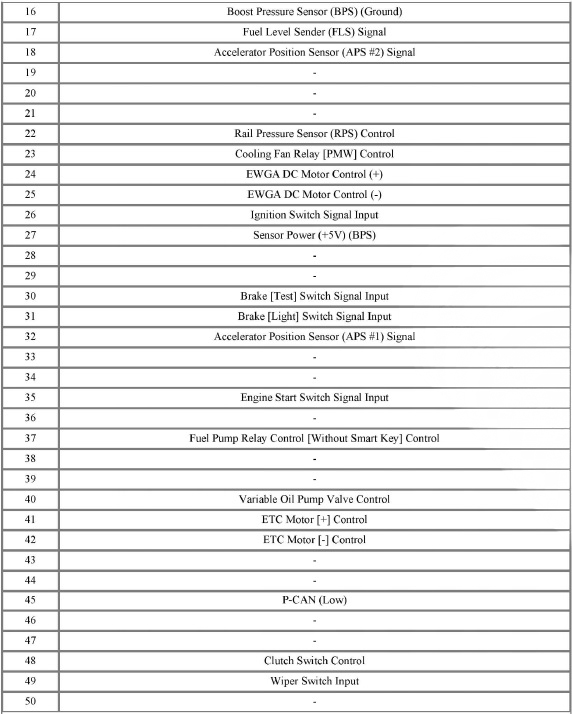

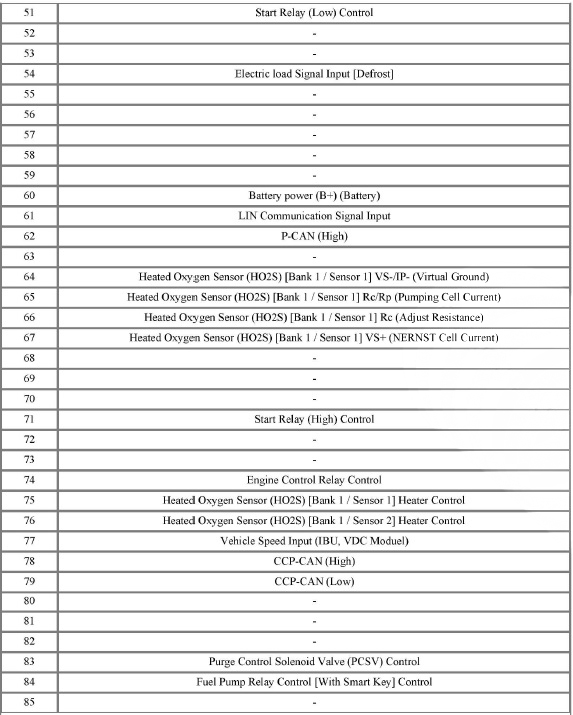

ECM Terminal Function

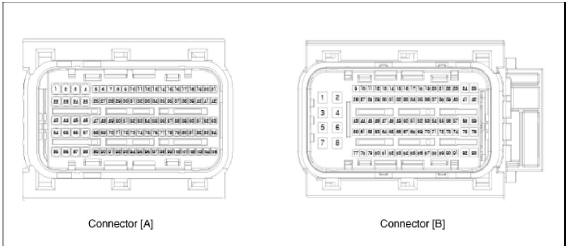

Connector A

Connector B

Engine Control Module (ECM) - Removal

Removal

- Turn ignition switch OFF and disconnect the battery negative (-) terminal.

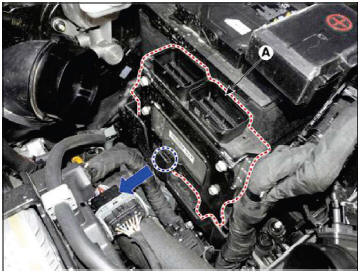

- Disconnect the ECM Connector (A).

- Remove the air cleaner assembly.

(Refer to Engine Mechanical - "Air Cleaner")

- Remove the ECM (A) after releasing the fixing hooks.

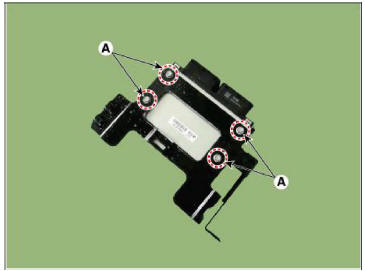

- Remove the ECM (B) after loosening the mounting bolts (A).

Tightening Torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

Engine Control Module (ECM)- Installation

Installation

- Install in the reverse order of removal.

Inspection

- TEST ECM GROUND CIRCUIT : Measure resistance between ECM and chassis ground using the backside of ECM harness connector as ECM side check point. If the problem is found, repair it.

Specification : Below 1

- TEST ECM CONNECTOR : Disconnect the ECM connector and visually check the ground terminals on ECM side and harness side for bent pins or poor contact pressure. If the problem is found, repair it.

- If problem is not found in Step 1 and 2, the ECM could be faulty. If so, make sure there were no DTC's before swapping the ECM with a new one, and then check the vehicle again. If DTC's were found, examine this first before swapping ECM.

- RE-TEST THE ORIGINAL ECM : Install the original ECM (may be broken) into a known-good vehicle and check the vehicle. If the problem occurs again, replace the original ECM with a new one. If problem does not occur, this is intermittent problem.

(Refer to "Intermittent Problem Inspection Procedure" in Basic Inspection Procedure)

Adjustment

ECM neutralization procedure (With immobilizer)

- When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below.

In the case of installing used ECM

1)Perform "ECM Neutral mode" procedure with diagnostic tool.

(Refer to Body Electrical System - "Immobilizer System")

2)After finishing "ECM Neutral mode", perform "Keyteaching" procedure with diagnostic tool.

(Refer to Body Electrical System - "Immobilizer System")

In the case of installing new ECM

- Perform "Key teaching" procedure with diagnostic tool.

(Refer to Body Electrical System - "Immobilizer System")

ECM Neutralization procedure (With smart key)

WARNING

When replacing the ECM, the vehicle equipped with the smart key system (Button start) must be performed procedure as below.

In the case of installing used ECM

1)Perform "ECM Neutral mode" procedure with diagnostic tool.

(Refer to Body Electrical System - "Smart Key Diagnostic")

2)After finishing "ECM Neutral mode", insert the key (or press the start button) and turn it to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

In the case of installing new ECM

- Insert the key (or press the start button) and turn it to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

ETC Module Learning Process

After replacing or re-installing the ECM, if you do not perform the ETC module learning procedure, the ETC module learning procedure must be performed since shift shock or failure code may be displayed.

(Refer to Engine Control System - "ETC System")

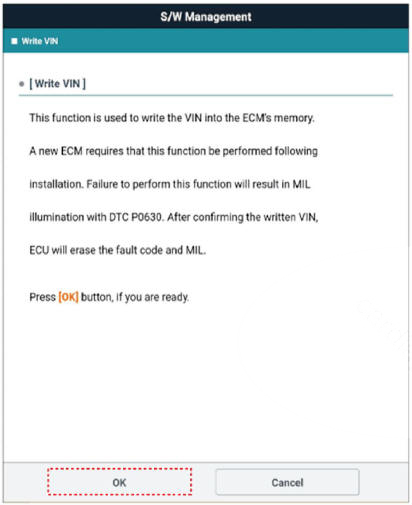

VIN Programming Procedure

VIN (Vehicle Identification Number) is a number that has the vehicle's information (Maker, Vehicle Type, Vehicle Line/Series.

Body Type, Engine Type, Transmission Type, Model Year, Plant Location and so forth. For more information, please refer to the group "GI" in this SERVICE MANUAL). When replacing an ECM, the VIN must be programmed in the ECM. If there is no VIN in ECM memory, the fault code (DTC P0630) is set.

WARNING

The programmed VIN cannot be changed. When writing the VIN, confirm the VIN carefully.

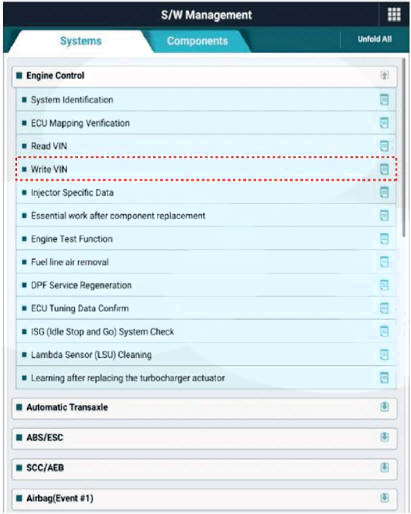

- Turn the ignition switch OFF.

- Connect the diagnostic tool to Data Link Connector (DLC).

- Turn the igntion switch ON.

- Select "Vehicle, Model Year, Engine, System".

- Select "Vehicle S/W Management".

- Select "Write VIN".

READ NEXT:

Mass Air Flow Sensor (MAFS)

Mass Air Flow Sensor (MAFS)

Description

MAFS uses a hot-film type sensing element to measure the mass of intake air

entering the engine, and

send the signal to ECM.

A large amount of intake air represents acceleration or high load conditions

while a small amount of

in

Boost Pressure Sensor (BPS)

Boost Pressure Sensor (BPS)

Description

Boost pressure sensor (BPS) is installed on top of intercooler output pipe to

measures the pressure of

supercharged air in the turbocharger.

Specification

Circuit Diagram

Harness Connector

Inspection

Connect th

ETC (Electronic Throttle control) System

ETC (Electronic Throttle control) System

Description

The Electronic Throttle Control (ETC) System consists of a throttle body with

an integrated control motor and throttle

position sensor (TPS). Instead of the traditional throttle cable, an Accelerator

Position Sensor (APS) is used to

SEE MORE:

Tires and wheels

Tires and wheels

WARNING

Tire failure may cause loss of

vehicle control resulting in an

accident. To reduce risk of SERIOUS

INJURY or DEATH, take the

following precautions:

Inspect your tires monthly for

proper inflation as well as wear

and damage.

&nb

Roll rod bracket

Roll rod bracket

Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

Remove the roll rod bracket (A).

Tightening torque :

Bolt (B): 107.9 - 127.5 N.m (11.0 - 13.0 kgf.m, 79.6 - 94.0 lb-ft)

Information

- Home

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Owner's Manual

- Hyundai Tucson - Fourth generation (NX4) - (2020-2023) - Workshop Manual